Mvh-200gh — maintenance – Multiquip MVH200GH User Manual

Page 25

MVH-200GH PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #2 (09/22/06) — PAGE 25

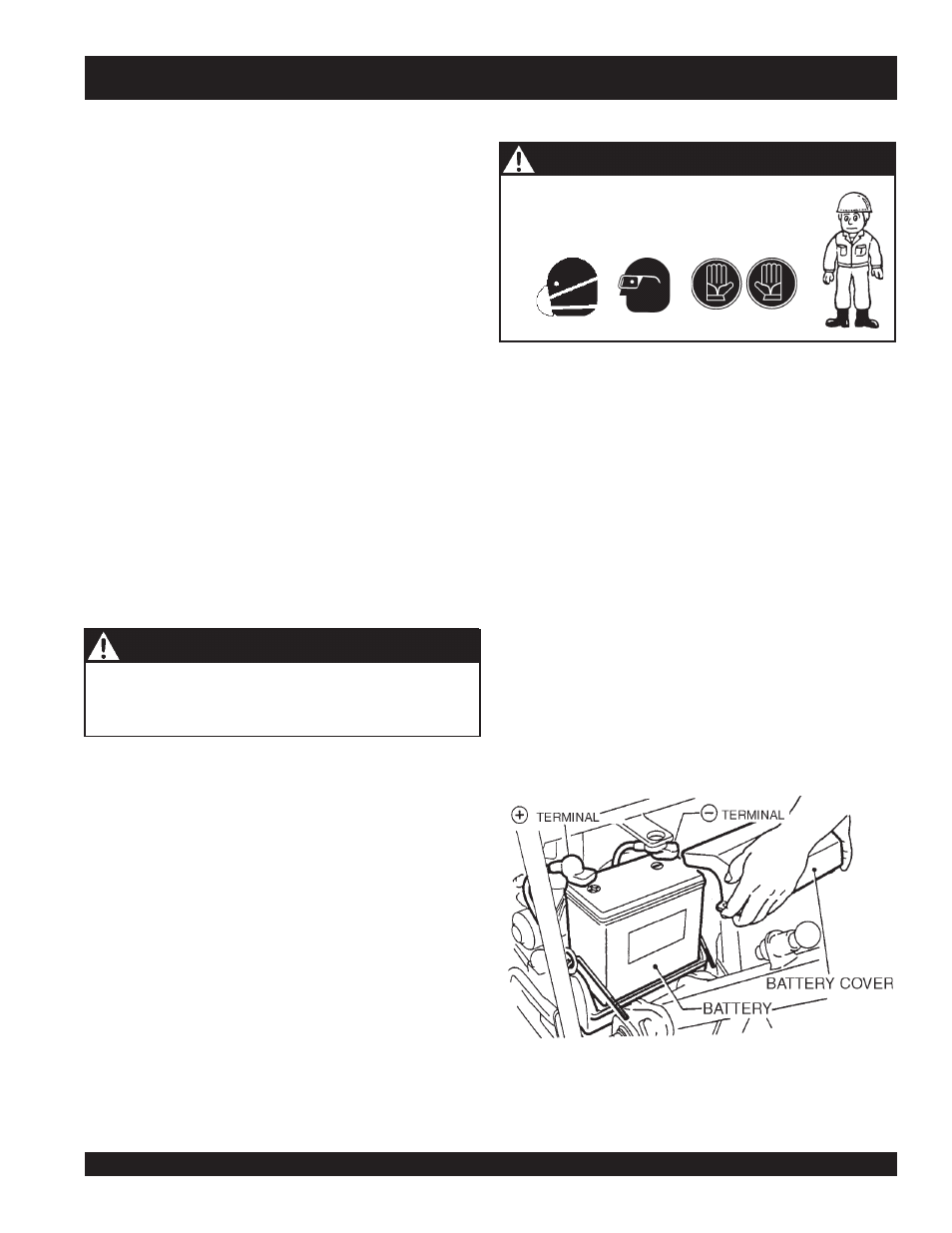

Figure 30. Battery Maintenance

Battery Cable Connection

1.

Take off the battery cover by removing the M6 nuts

(Figure 30).

2.

When removing cable, disconnect the ground side (normally

negative) first (Figure 30).

3.

When installing cable connect the ground side (normally

negative) last.

Battery Maitenance

MVH-200GH — MAINTENANCE

Make sure that hand pump is filled with hydraulic oil to the

specified level. Excessive oil may hinder bleed valve function,

resulting in poor reverse performance.

CAUTION - Overfilling the Hydraulic Oil Resevoir

5.

Filling the reverse travel circuit with oil

.

a. With the travel lever pushed forward (hydraulic circuit is

connected with reverse travel circuit), add oil into pump

and remove bleed plug of vibrator cylinder (opposite of

belt cover side). In a few seconds, oil will come out of

bleed plug.

b. When aeration disappears, reinstall the plug tightly.

c. Move the travel lever slowly until aeration in the hand

pump disappears (about 10 to 15 times).

6. When the aeration in the pump disappears, with the travel

lever pushed forward, reinstall the valve. Be careful not to

drop the packing into pump. The bleeding valve tightening

torque is 450 to 500 kg-gm.

7. After installing the bleed valve, moving the travel lever all the

way to reverse causes excess oil to be discharged into pump.

If valve fails to activate, aeration still remains in the circuit.

With the bleed valve removed, operate travel lever again to

bleed. If valve is activated, move the travel lever forward to

activate the valve inside spool before moving it to reverse to

activate the bleed valve. Repeat 3 to 4 times.

8. After making sure that the hydraulic oil in the pump is at the

specified level, reinstall the reservoir cover. Coat both sides

of packing with liquid packing (such as Threebond #1215).

9. After adding oil and reinstalling the reservoir cover, operate

the travel lever to make sure of the following:

a.

spool valve:

when pushed forward, resistance is felt in

two-stage motion.

CAUTION - Battery Maintenance Safety

1.

Check the battery terminals periodically to ensure

that they are in good condition.

2.

Use wire brush or sand paper to clean the battery

terminals.

3.

Check battery for cracks or any other damage. If white

pattern appears inside the battery or paste has

accumulated at the bottom, replace the battery.

4.

If the machine will not be in operation for a long

period of time, store in cool dry place and check the

battery charge level every month to maintain the

performance of the battery.

Wear

safety glasses

or

face mask, protective

clothes

, and

rubber gloves

when working with

battery.