Mtr-60l — operation – Multiquip MTR60L User Manual

Page 13

MTR-60L — PARTS & OPERATION MANUAL — REV. #7 (06/26/01) — PAGE 13

MTR-60L — OPERATION

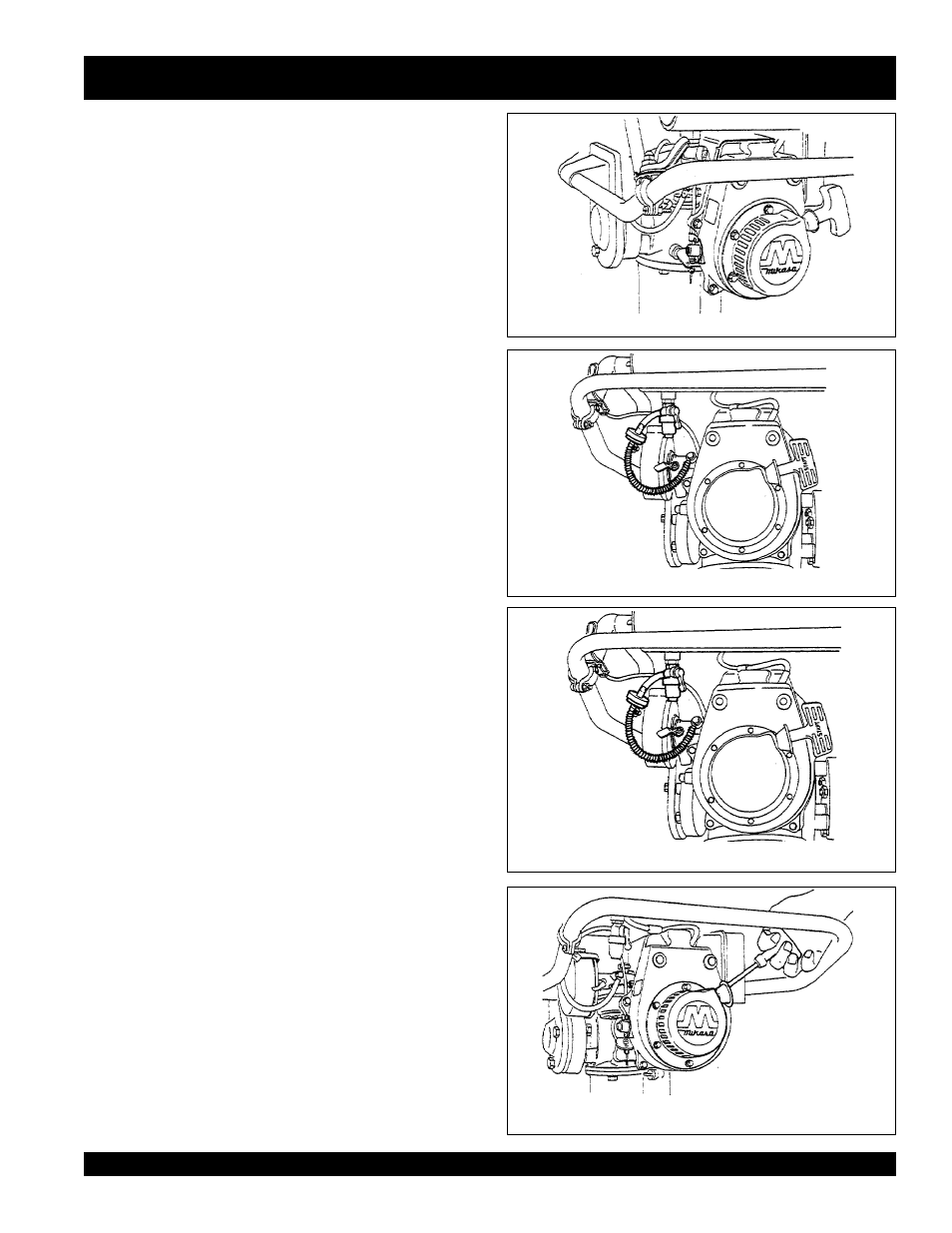

Fig. 5 — Clean around the recoil starter

3. Operation

3-1.

Move the throttle lever (Figure 10) from the “off” to the “on “

position.

Make sure that the throttle lever is moved to the fully

“on” position (Fig. 10).

Operating the rammer at half speeds can

result in damage to the clutch or springs.

3-2.

The rammer is designed to tamp the ground 550 to 600

times per minute at an engine speed of 4000 rpm.

NOTE:

Increasing the engine speed above the recommended operating

engine speed will not increase the effectiveness of the rammer.

Impact actually decreases

as a resonance is created rather than

a tamping effect.

Damage can result to the unit. Running the

rammer over hard surfaces such as concrete and asphalt are

not recommended as damage to the machine may result.

3-3.

In cold weather, the grease in the rammer is stiff and may

not allow the rammer to operate smoothly.

The tamper can be

warmed by moving the throttle lever from the “on” to the “off”

position several times until the grease is heated and the rammer

operates smoothly.

3-4.

The rammer is designed to travel forward while tamping.

To

increase the travel speed of the rammer, push down lightly on

the handle. Open blows or running the rammer without contacting

the soil is not recommended.

3.5.

Check for oil leaks and retighten bolts.

The tamping rammer

may be greased daily as paragraph 5-2; however, weekly

greasing is sufficient.

4. Stopping the engine

4-1.

Turn the throttle lever to the

“idle” position and allow the

engine to run at an idle speed for 2 to 3 minutes to allow the

temperature of the engine to cool, then stop the engine by pushing

the “stop” button (Fig. 11).

5. Service

5-1.

DAILY

Thoroughly remove mud, dirt, and oil from the machine.

Check

the air cleaner element and clean or replace it as necessary.

Check all bolts for tightness.

5-2.

WEEKLY (every 50 hours)

Remove the air cleaner element and wash it in a neutral detergent

solution.

Shake out excess moisture and dry the element.

Lubricate

the element with a two-cycle engine fuel mix and squeeze out the

excess moisture.

Reinstall the air cleaner element.

Under extreme

conditions, the tamping rammer may be greased daily.

Under normal

conditions, add 6 shots of grease to all three lubrication points every

2 weeks.

Be sure to use MQ HIGH TEMPERATURE GREASE

(PART #GRS2) or it’s generic equivalent Bentone base EP#2 grease.

(Shell Darina EP2)

Fig. 7 — Closing the choke lever

Fig. 8 — Pull the grip forcibly after slight

resistance is felt

Fig. 6 — Move the fuel cock downwards