Meltric PFQ User Manual

Pf/pfq, Operating instructions, Warning

gENERAL

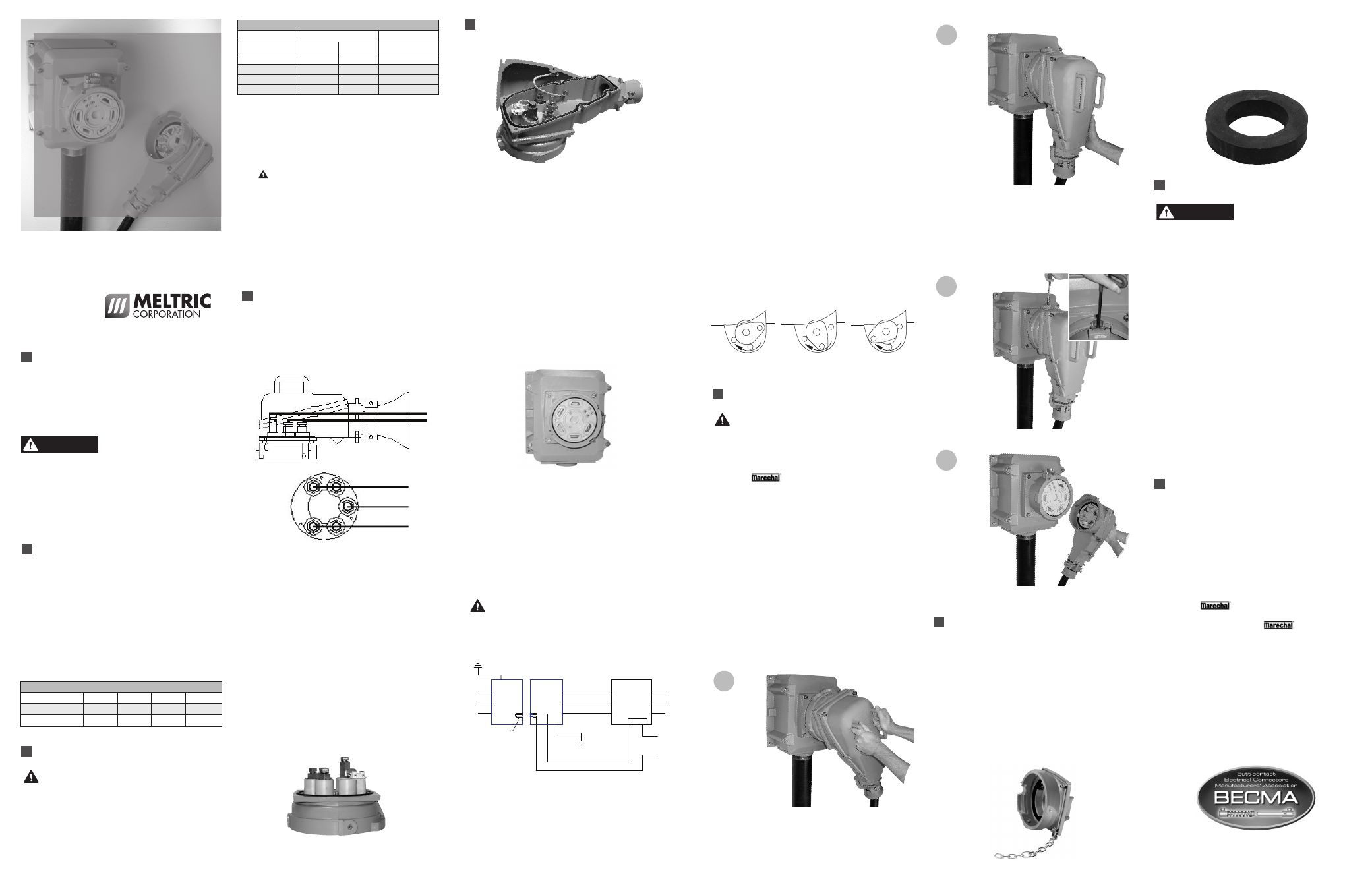

PF and PFQ Series plugs and receptacles are engi-

neered for use in high amperage applications where

routine plug insertion and high reliability are required.

To ensure proper installation and use of the product,

please follow all of the instructions carefully.

There are inherent dangers

associated with electrical

products. Failure to follow safety precautions can

result in serious injury or death. These instructions

must be followed to ensure the safe and proper

installation, operation and maintenance of the Meltric

devices. Before installation, disconnect all sources of

power to the circuit to eliminate the risk of electrical

shock. In order to prevent disconnection under

load, electrical interlocking is required.

RATINgS

PF and PFQ Series plugs and receptacles are UL

and CSA listed according to UL 1682 and CSA C22.2

No.182.1 These listings only apply for 300A and

400A devices at 600V or less. 600A devices are

not UL or CSA listed. WARNINg! All PF and PFQ

devices are provided with manually operated auxiliary

contacts that must be wired to the coil of a contactor

or similar switching device to prevent accidental con-

nection or interruption of live main power contacts.

See schematic for safety circuit example. The ratings

for auxiliary contacts are shown in Table 1.

INSTALLATION

PF and PFQ devices should be installed by

qualified electricians in accordance with all

applicable local and national electrical codes.

Before starting verify that the power is off, that the

product ratings are appropriate for the application,

and that the conductors meet NEC code require-

ments. Tools required for installation include 7/8”

(22mm) wrench or socket, 5/16” (8mm) allen wrench

and 10 mm wrench for PFQ only.

Recommended Torques:

Main Contacts: 30 ft-lb. (40 N-m)

Aux/Pilot Contacts: 15 in-lb (1.80 N-m).

general Notes & Precautions

1.

To prevent short circuiting the heat shrink

sleeves provided must be used over lugs and

terminals after wiring.

2. The PF and PFQ inlets and receptacles and

handles are symmetrical and thus they can be

mounted in any of four positions provided that

the locking cam on the receptacle remains easily

accessible.

3. Lugs are not included with devices unless ordered.

WIRINg INSTRUCTIONS

The cable sheath should extend at least 2 in. into

handle or junction box.

For Plug or Connector with Angled handle

or Receptacle on Box or Inlet on Box

• Use straight type compression lugs with 9/16”

or 5/8” hole.

• Run the neutral & ground wires above the phases.

• Apply heat shrink over lugs at terminals.

For Plug or Connector with Straight handle

• Use 90° lugs with 9/16” or 5/8” hole. Arrange

the 90° lugs to minimize the possibility of lugs

touching

• Run the neutral & ground wires above the phases.

• Apply heat shrink over lugs at terminals.

NOTICE: Lugs crimped on the conductors must be

bolted on the terminals with the supplied M14 screws

and washers. In order not to transmit this torque to

the molding, contact bodies should be held with a

suitable wrench when tightening the M14 screw.

The phase contacts are lower to allow the passage

of the ground and neutral above the phases.

ASSEMBLY

Angled handle to Inlet or Receptacle Assembly

1. Attach inlet or receptacle to handle body then

open cover on handle.

2. Connect the conductors to the terminals as

described previously in ‘wiring instructions.’

3. Attach handle cover using a 8mm allen tool and

6 screws supplied.

4. Compress grease coated cable gland by tightening

hub. NOTICE: The recommended torque to

achieve IP 67 is 150 to 280 ft-lb (200-400 N-m),

depending on cable jacket material and diameter.

5. Then tighten the cable clamps.

Junction Box to Inlet or Receptacle Assembly

1. Attach junction box to conduit. Attach cover to

junction box using bolts provided.

2. Connect conductors to terminals as described

previously in ‘wiring instructions.’

3. Mount receptacle or inlet to junction box cover

using bolts provided.

Auxiliary/Pilot Contacts

In order to prevent disconnection under load

electrical interlocking is required. Failure to do

so could result in death or serious injury.

Typical PF/PFQ Control Circuit

PF: The four pilot/auxiliary terminals are numbered

1 to 4 and color coded. Conductors must be stripped

by 0.5 in (12 mm) and fully inserted into their respec-

tive spring-assisted, tunnel type terminals. Tighten ter-

minal screws until hand tight with a 4 mm flat screw-

driver. Recommended torque is 13 in-lb (1.5 N-m).

Terminals will accept flexible conductors up to 10

AWG (6 mm

2

).

Table 2 - Wiring Terminal Capacity

Main Contacts Aux. Contacts

Device Minimum Maximum Maximum

PFQ - 300A 4/0 AWG 350 MCM 10 AWG

PF - 300A 250 MCM 600 MCM 10 AWG

PF - 400A 250 MCM 600 MCM 10 AWG

PF - 600A 250 MCM 600 MCM 10 AWG

FEMALE PILOT

CONTACTS

MALE PILOT

CONTACTS

PILOT CIRCUIT

C

B

A

PF/PFQ

LOAD

TO

LINE

SWITCH ETC.

POWER

COIL

PILOT CIRCUIT

PHASE

RECEPTACLE/

INLET/PLUG

PF/PFQ

C

B

A

CONNECTOR

CONTACTOR

OR

BREAKER WITH

UNDER VOLTAGE

TRIP

JUMPER 2 PILOT

CONTACTS TO

COMPLETE CIRCUIT

NOTE:

ROTATE RECEPTACLE LOCKING

CAM TO ENGAGE PILOTS

Table 1 - Auxiliary Contact Ratings

Device 120vAC 240vAC 480vAC 600vAC

PFQ300 7A 5A 2A* 2A*

PF series 10A* 10A* 10A* 10A*

* Rating is not UL or CSA listed.

PF/PFQ

OPERATING INSTRUCTIONS

Meltric Corporation

/ 4640 Ironwood Drive Franklin, WI 53132

Tel. : 800 433 7642 / Fax : 414 817 6161 / e-mail : [email protected]

INSPF_PFQ D

A manufacturer of products using Marechal technology

meltric

.com

PFQ: Eight pilot/auxiliary contacts are prewired and

identified. Pilots are marked P1 and P2, whereas

auxiliary contacts are numbered 3 to 8. Conductors

provided have a cross-section of 14 AWG (1.5 mm

2

).

Mechanical Locking: PF Series

The cam has two positions:

Position 1: Unlocked, auxiliary/pilot contacts opened.

Position 2: Locked, auxiliary/pilot contacts closed.

The plug is live and can not be removed.

Mechanical Locking: PFQ Series

The cam on the receptacle has three positions:

Position 1: Unlocked, auxiliary and pilot contacts

opened. The cover or plug can be removed.

Position 2: Locked, pilot contacts opened. The

cover or plug can not be removed but pilot

contacts remain open.

Position 3: Locked, auxiliary and pilot contacts

closed. The plug is live and can not be removed.

Cam can be locked out in any of the three positions.

OPERATION

To ensure safe and reliable operation Meltric

plugs and receptacles must be used in

accordance with their assigned ratings.

They can only be used in conjunction with mating

receptacles or plugs manufactured by Meltric or

another licensed producer of products bearing the

Marechal

technology trademark.

Meltric plugs and receptacles are designed with

different keying arrangements, so that only plugs and

receptacles with compatible contact configurations

and electrical ratings will mate with each other.

Connection

1. Insert the plug into the receptacle. This unlocks

the safety shutter on the receptacle and allows

it to rotate.

2. Rotate plug approximately 30° clockwise to

engage the phase contacts and to make the

unit watertight. Turn the cam/mechanical lock

to secure the receptacle and engage the pilot

contacts which energize the circuit.

Disconnection

1. Turn the cam/mechanical lock to disengage the

pilot contacts and deenergize the circuit.

2. Twist plug 30° counterclockwise to disengage

the phase contacts. Withdraw plug.

AChIEvINg RATED WATERTIghTNESS

NOTICE: Proper steps must be taken to maintain

water tightness at NPT fittings on the plug handles or

at the junction box. The use of a sealer tape is

recommended.

IP 66/67 rated ingress protection applies to the

device when the plug and receptacle are fully mated.

When not in use the plug/inlet or connector/receptacle

can be kept watertight by utilizing the protective cap.

Caps are fully engaged when inserted into

receptacle/inlet, rotated 30° clockwise and

secured in place with the locking cam.

Using the correct bushing and compression washer

size is important. The bushing must have as close

a size as possible to the outer cable diameter. The

portion of the cable that passes through the bushing

must be as circular as possible to maintain ingress

protection.

MAINTENANCE

Before inspecting, repairing, or

maintaining Meltric products,

disconnect electrical power to the receptacle to

eliminate the risk of electrical shock.

Meltric products require little ongoing maintenance.

However it is good practice to periodically perform

the following general inspections:

• Check the mounting screws for tightness.

• Verify the weight of the cable is supported by

the strain relief mechanism and not by the

terminal connections.

• Check the IP gaskets for wear and resiliency.

Replace as required.

• Verify the electrical continuity of the ground circuit.

• Check the contact surfaces for cleanliness.

Deposits of dust or similar foreign materials can be

rubbed off the contacts with a clean cloth. Sprays

should not be used, as they tend to collect dirt. If

any significant pitting of the contacts or other serious

damage is observed they should be replaced.

MANUFACTURER’S RESPONSIBILITY

Meltric’s responsibility is strictly limited to the repair

or replacement of any product that does not conform

to the warranty specified in the purchase contract.

Meltric shall not be liable for any penalties or conse-

quential damages associated with the loss of produc-

tion, work, profit or any financial loss incurred by the

customer.

Meltric Corporation shall not be held liable when its

products are used in conjunction with products not

bearing the technology trademark. The use

of Meltric products in conjunction with mating devices

that are not marked with the technology

trademark shall void all warranties on the product.

Meltric Corporation is an ISO 9001 certified company.

Its products are designed, manufactured and rated

in accordance with applicable UL, CSA and IEC

standards. Meltric is also a member of BECMA, the

international Butt-contact Electrical Connectors

Manufacturers’ Association. Like all members,

Meltric additionally designs and manufactures its

products in accordance with BECMA standards

established to ensure intermatablility with similarly

rated products manufactured by other members.

1

2

1

2

Position 1 Position 2 Postion 3

INSPF_PFQ D

WARNING

WARNING