System start-up, Vii. system start-up – Burnham 20_PV_I User Manual

Page 13

13

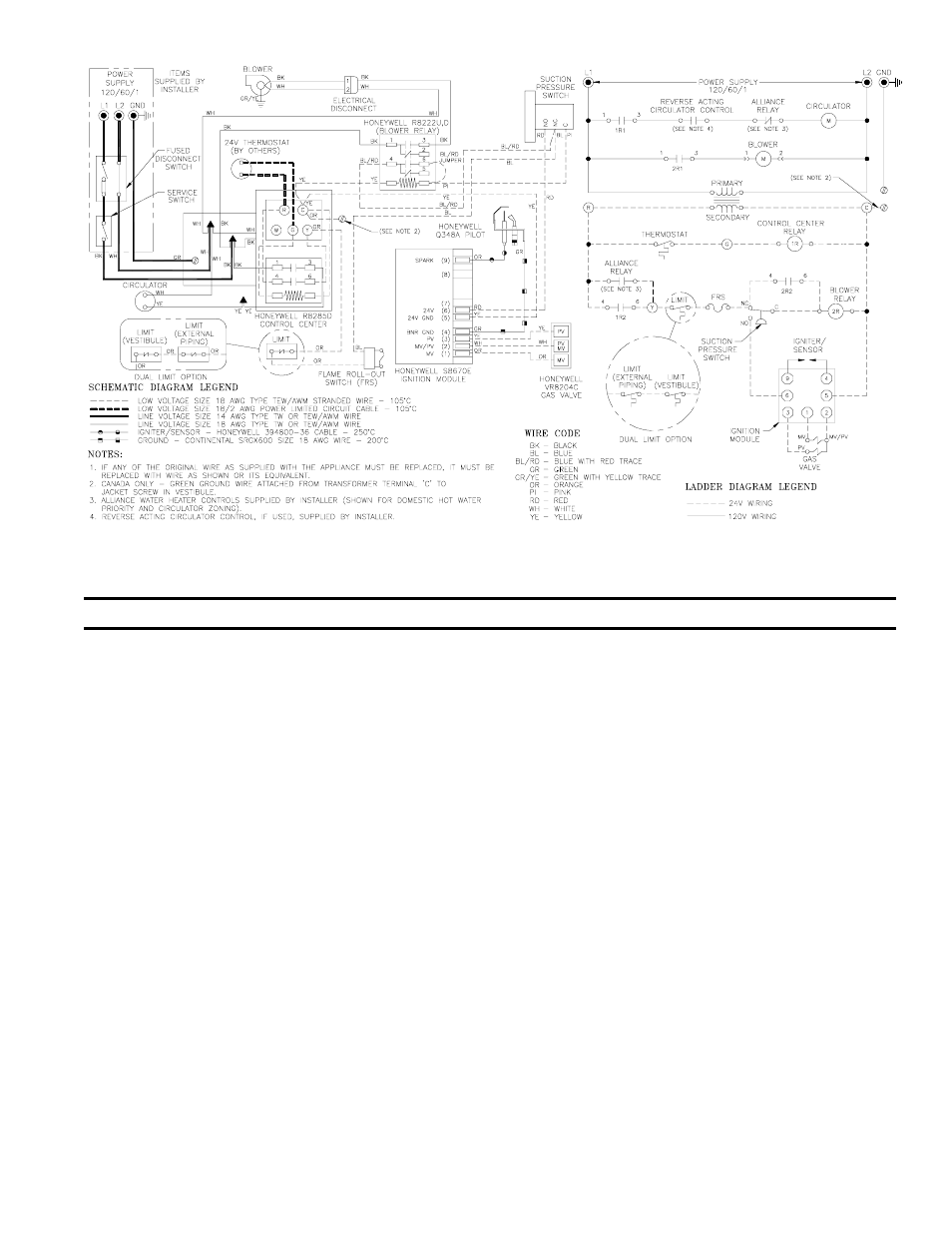

Figure 10: Wiring Diagram

Figure 11: Main Burner Installation

VII. System Start-up

A.

Safe operation and other performance criteria were

met with gas manifold and control assembly provided

on boiler when boiler underwent tests specified in

American National Standard for Gas-Fired Low-

Pressure Steam and Hot Water Boilers, ANSI Z21.13.

B.

Fill heating system with water and vent air from

system. Use the following procedure on a Series Loop

System equipped with zone valves. See Figure 3.

1. Close isolation valve in boiler supply piping.

2. Isolate all circuits by closing zone valves or

balancing valves.

3. Attach hose to bib cock located just below isolation

valve in boiler supply piping. Terminate hose in

five gallon bucket at a suitable floor drain or

outdoor area).

4. Starting with one circuit, open zone valve.

5. Open bib cock.

6. Open fill valve. Makeup water line should be

located directly above isolation valve in boiler

supply piping.

7. Allow water to overflow from bucket until

discharge from hose is bubble free for 30 seconds.

8. Open zone valve to second zone to be purged, then

close first. Repeat this step until all zones have been

purged, but always have one zone open. At

completion, open all zone valves.

9. Close bib cock, continue filling system until

pressure gauge reads 12 psi. Close fill valve.

Note: If makeup water line is equipped with

pressure reducing valve, system will automatically

fill to 12 psi. Leave globe valve open.

10.Open isolation valve in boiler supply piping.

11.Remove hose from bib cock.

C.

Check main burners. See Figure 11. Rear of burner

must be in vertical slot in rear of burner tray. Front of

burner must be seated on orifice.