Longevity MIGWELD 140 User Manual

Page 20

MigWeld 140 140 AMP MIG Welder

Page 20 of 27

6

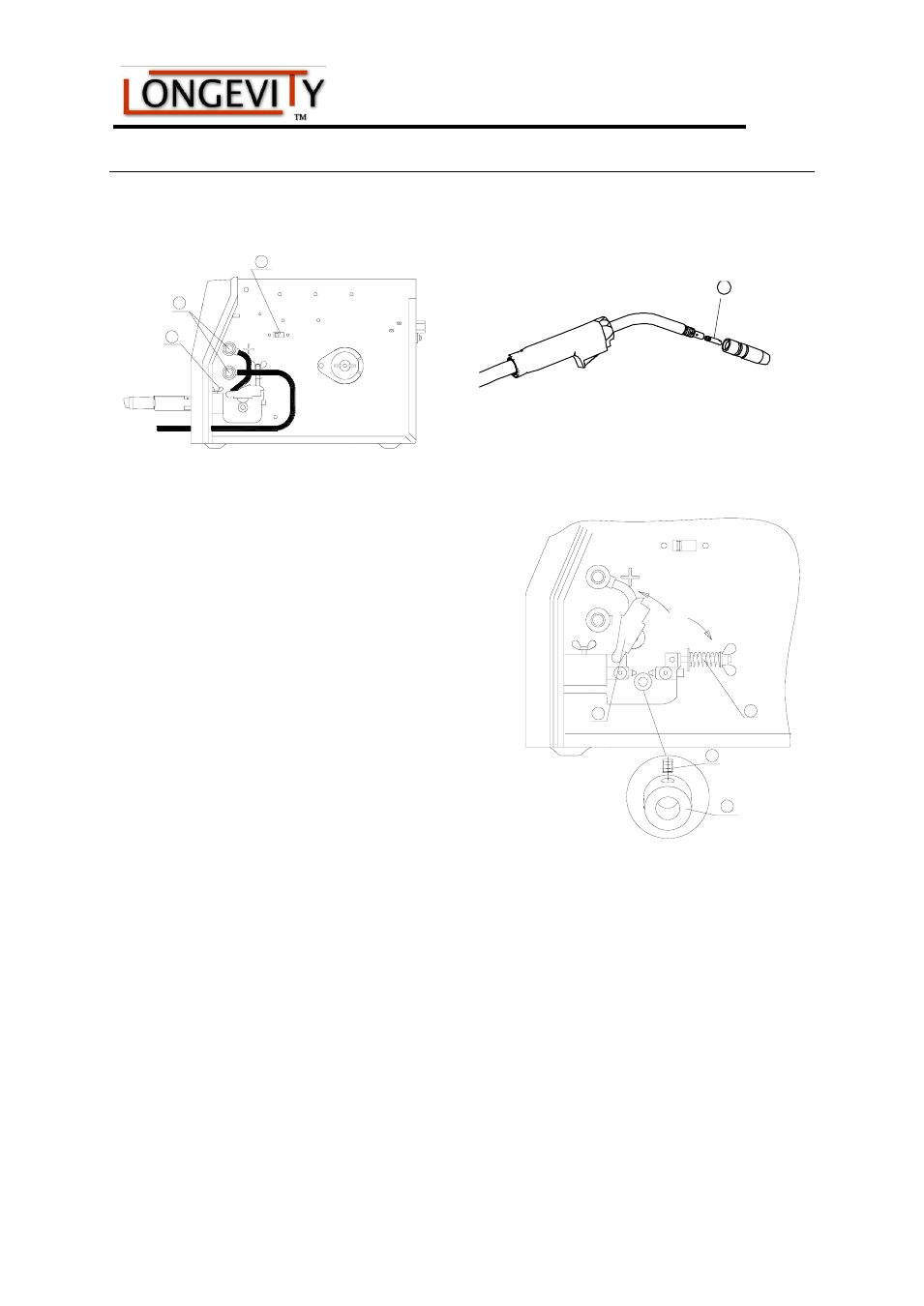

Figure C-3

3. Tighten the wing screw ○

3

attached to the connector block of the wire feed gearbox.

4. Make sure the Gun changing switch ○

7

is in the correct position MIG for standard

welding and Spool Gun if optional gun is installed.

Wire Drive Roll Installation (See Figure C-4)

The reversible dual groove wire drive roll

attached to MigWeld140 has two wire grooves;

One for .025” (0.6mm) solid welding

wire and the other for .030-.035” (0.8-0.9mm)

solid or flux-cored welding wire. The

factory default installation is .025” (0.6mm)

.

In the event that .030” (0.8mm) - .035”

(0.9mm) welding wires are used, the wire feed

roll groove must be changed.

1. Ensure that the MigWeld 140 welding machine is

powered off.

2. Unlatch the spring loaded pressure arm and Figure C-4

open the idle roll arm. ○

1

and lift up the idle

roll arm. ○

2

3. Loosen the hex bolt ○

3

that attaches the wire drive roll.

4. Remove the wire drive roll○

4

and flip the wire drive roll over so that the .030” (0.8mm)

mark faces the user.

5. Reinstall by putting back the wire drive roll and tighten the hex bolt.

4

3

1

2

7

Figure C-2

3

4