Bryant 564A User Manual

Page 10

2. Refer to appropriate chart to determine what the suction

temperature should be.

3. If suction temperature is high, add refrigerant. If suction

temperature is low, carefully recover some of the charge.

4. Recheck the suction pressure as charge is adjusted.

EXAMPLE: (Fig. 17)

Outdoor Temperature .....................85° F

Suction Pressure .......................80 psig

Suction Temperature should be .............70° F

(Suction Temperature may vary

±5˚ F.)

If Chargemaster® charging device is used, temperature and

pressure readings must be accomplished using the charging

chart.

IV.

INDOOR AIRFLOW AND AIRFLOW ADJUSTMENTS

CAUTION: For cooling operation, the recommended

airflow is 350 to 450 cfm per each 12,000 Btuh of rated

cooling capacity.

Table 4 shows dry coil air delivery for horizontal discharge units.

Tables 5-7 show pressure drops.

NOTE: Be sure that all supply- and return-air grilles are open,

free from obstructions, and adjusted properly.

WARNING: Disconnect electrical power to the unit

before changing blower speed. Electrical shock can cause

serious injury or death.

Airflow can be changed by changing the lead connections of the

blower motor.

Units 564A036,048, and 060 blower motors are factory wired for

low speed operation. Unit 564A042 is factory wired for medium

speed operation.

A.

For 208/230-v

The motor leads are color-coded as follows:

3-SPEED

2-SPEED

black = high speed

black = high speed

blue = medium speed

-

red = low speed

red = low speed

To change the speed of the blower motor (BM), remove the fan

motor speed leg lead from the indoor (evaporator) fan relay (IFR)

and replace with lead for desired blower motor speed. Insulate the

removed lead to avoid contact with chassis parts.

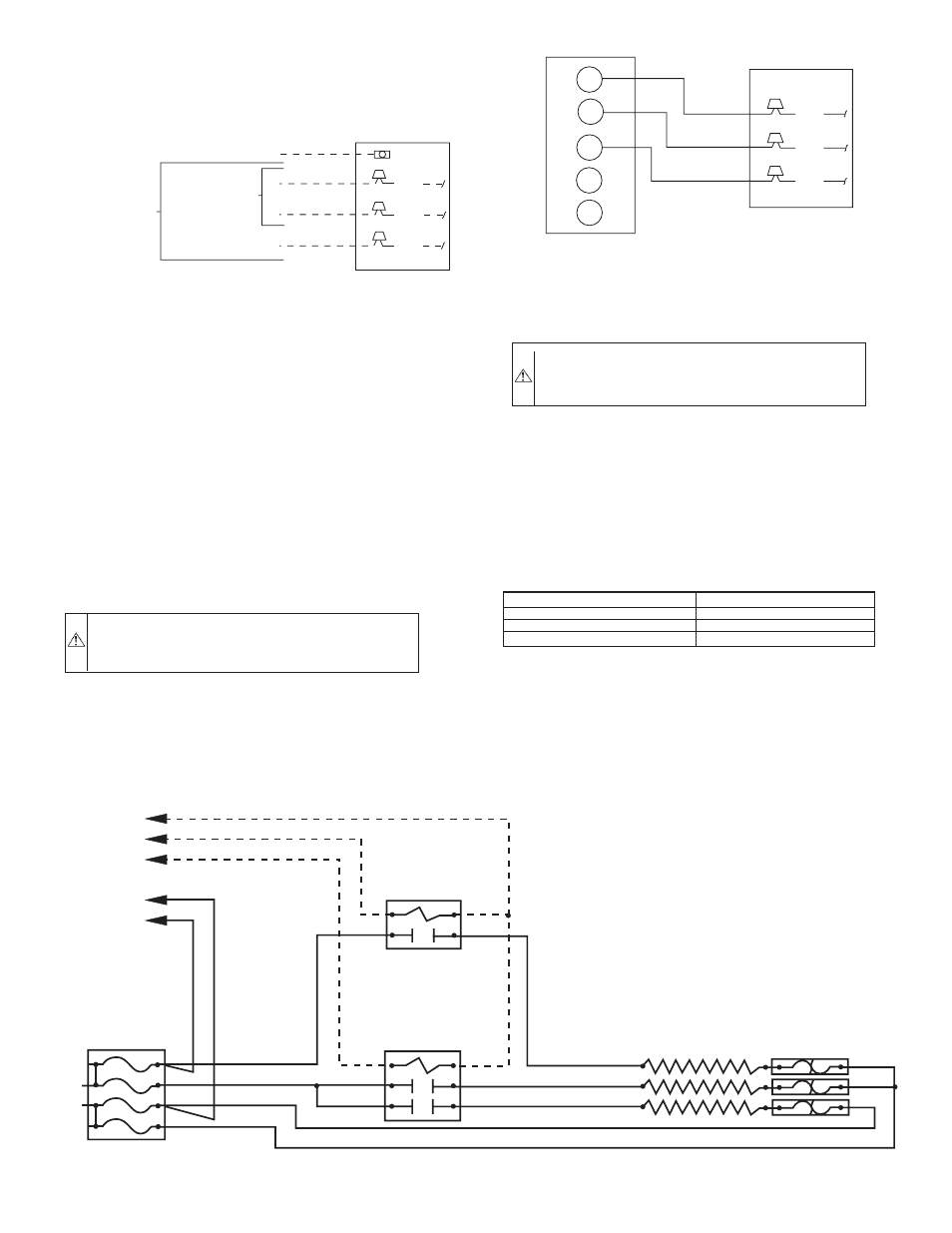

Fig. 12—Line Power Connections

C00012

3-PHASE

CONNECTIONS

TO DISCONNECT

PER NEC

SINGLE-PHASE

CONNECTIONS

TO DISCONNECT

PER NEC

GROUND

LEAD

UNIT GROUND

BLK

YEL

BLU

L

L

L

Fig. 13—Control Connections

C00013

R

G

Y

W1

W2

RED

GRN

YEL

UNIT CONTROL BOX

THERMOSTAT

AND SUBBASE

Fig. 14—Accessory Electric Heater Wiring

C00014

C

W1

W1

TO

UNIT POWER

WIRING

BLK

YEL

BRN (COMMON)

VIO (STEP 2)

WHT ( STEP 1)

CONTACTOR 2

YEL

BRN

YEL

CONTACTOR 1

YEL

YEL

BRN

YEL

YEL

FUSE BLOCK

L2

L1

YEL

YEL

BLK

BLK

F3

F4

F1

F2

EL 1

EL 2

EL 3

BLK

BLK

BLK

AUTO-LIMIT

—10—