Preparations 5.1. installation, Bath fluids – JULABO SL-14K Calibration Baths User Manual

Page 18

Preparations

18

5. Preparations

5.1. Installation

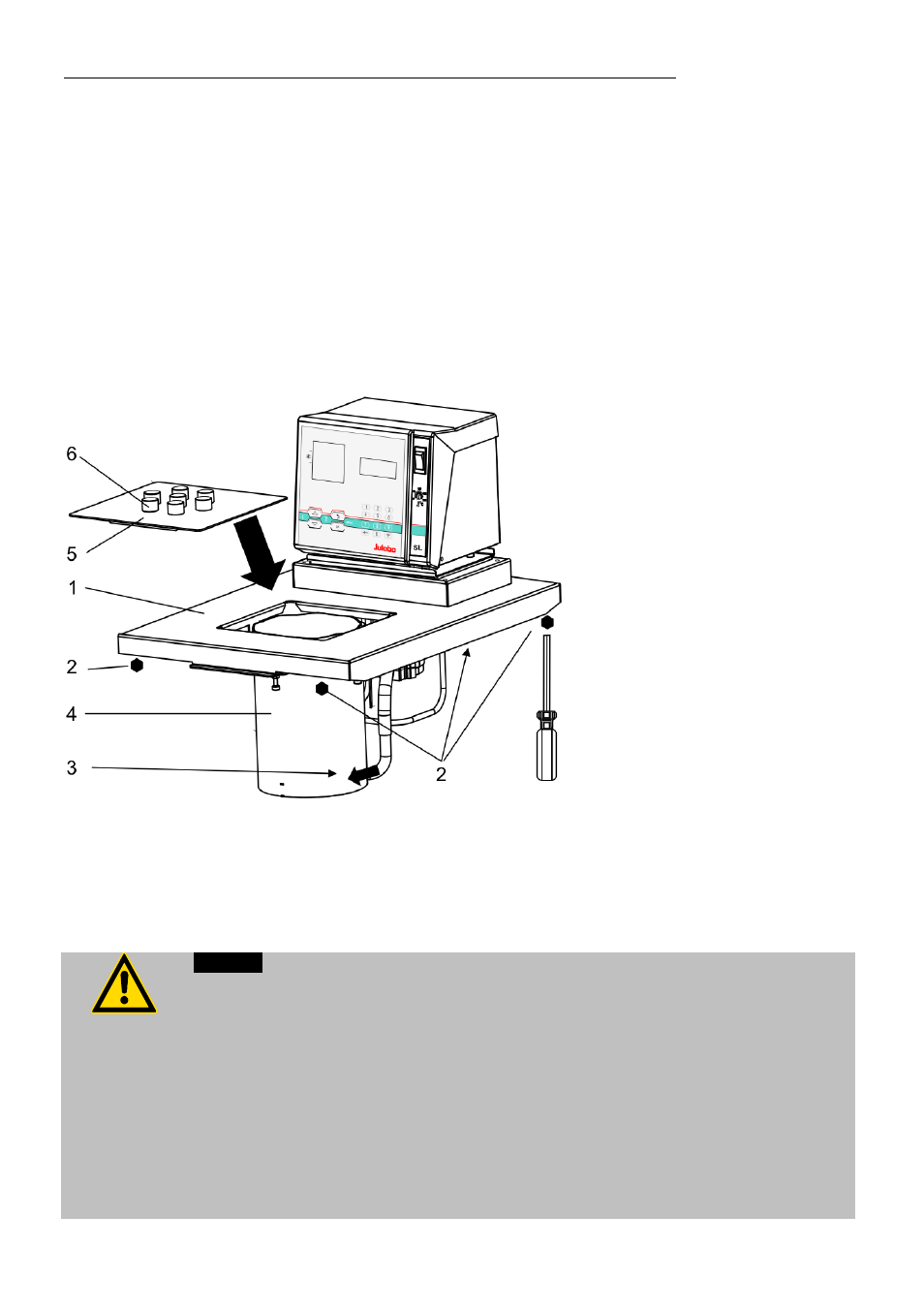

Place the unit on an even surface on a pad made of non-flammable

material.

Pump motor and electronics produce intrinsic heat that is dissipated

via the venting openings! Never cover these openings!

Do not set up the unit in the immediate vicinity of heat sources and

do not expose to sun light

The bath cover (1) is mounted on the bath tank with 4 captive screws (2).

Required tool: SW3 hexagonal socket wrench with ball-shaped head

The circulating pump transports the

bath fluid to the temperature

chamber (4) at the bottom (3). The

overflow on top of the chamber

ensures a constant fluid level during

operation.

The bath cover (5) provides 6

measuring places (6) that can be

fitted with different Viton

®

sleeves..

Order-No.: Viton

®

sleeves

8 930 602

2 mm inner dia.

8 930 603

3 mm inner dia.

8 930 604

4 mm inner dia.

8 930 605

5 mm inner dia.

8 930 605

6 mm inner dia.

8 930 608

8 mm inner dia.

Take off the complete insert for cleaning. The gasket below the bath

cover should be replaced in this case.

Part No.: 7.901.1087 Gasket for bath cover 8K / 14K

5.2. Bath fluids

Caution:

Carefully read the safety data sheet of the bath fluid used, particularly with regard to

the fire point!

If a bath fluid with a fire point of

65 °C is used, only supervised operation is possible.

Water: The quality of water depends on local conditions.

Due to the high concentration of lime, hard water is not suitable for temperature

control because it leads to calcification in the bath.

Ferrous water can cause corrosion - even on stainless steel.

Chloric water can cause pitting corrosion.

Distilled and deionized water is unsuitable. Their special properties cause

corrosion in the bath, even in stainless steel.