JULABO FLW20006 Recirculating Coolers User Manual

Page 13

13

Caution:

Pump

pressure

Determine and check the max. admissible pressure for the external circuit before

putting the unit into operation. The max. pressure is determined by the weakest

element in the circuit (e. g. glass equipment).

Securely attach all tubing to prevent slipping.

Do not seal the overflow!

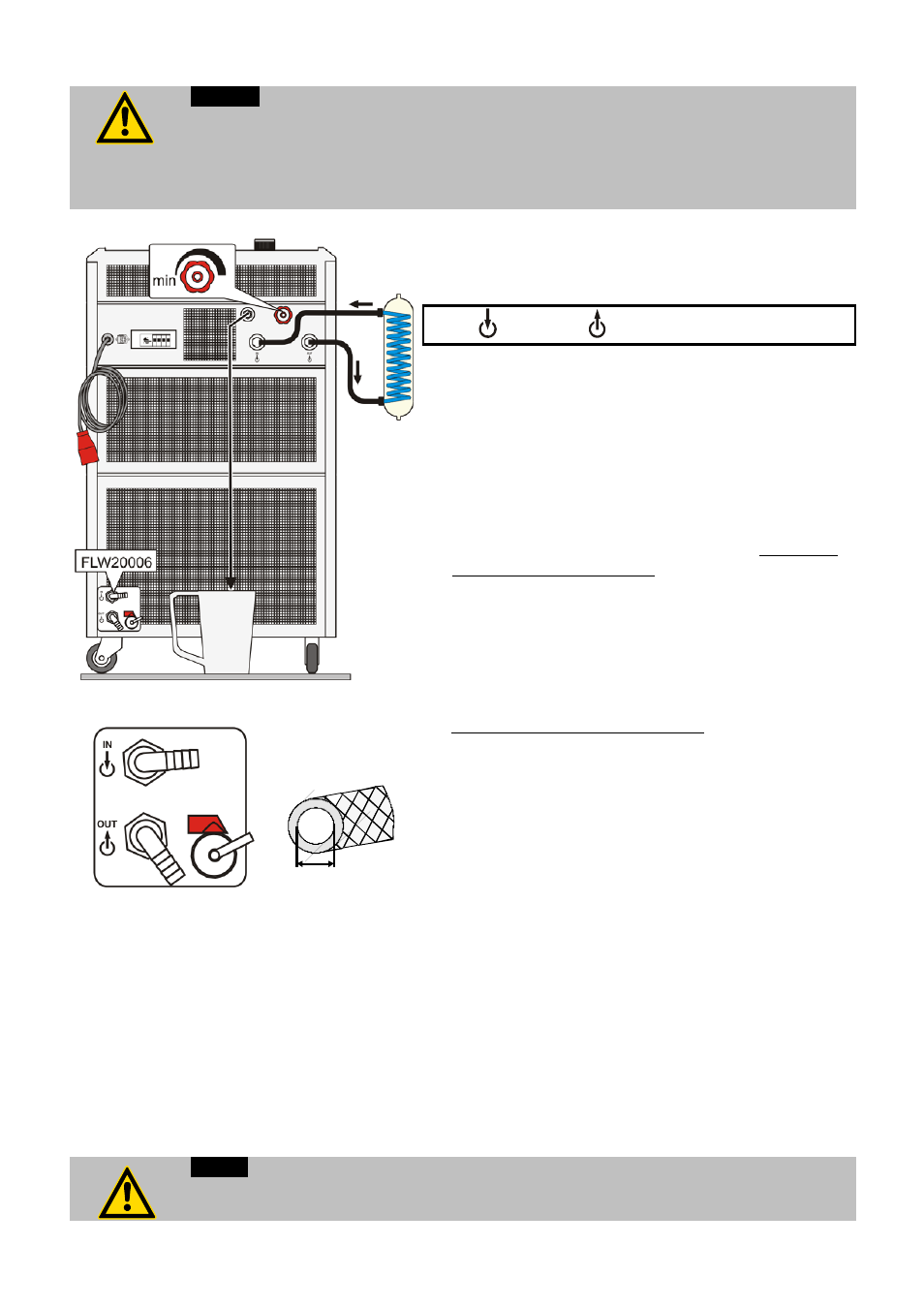

Connect the tubings for cooling the external system

to the pump connectors M16x1 for feed and return

(14) on the rear of the recirculating cooler.

– Return

- Feed

Connect a piece of tubing to the overflow connector

(15) and drain into a suitable vessel, which always

has to be placed lower thant the exit „Overflow“.

Do not seal the overflow connector!

Turn the adjusting valve (13) counter-clockwise to

set the lowest manometric pressure.

Before operating the unit after transport, wait about

one hour after setting it up. This will allow any oil

that has accumulated laterally during transport to

flow back down thus ensuring maximum cooling

performance of the compressor.

¾”

Only water cooled models - FLW:

Ensure circulation of cooling water by connecting

the tubing to cooling water inlet (IN)and outlet (OUT)

on the rear (18) of the recirculating cooler.

Cooling water see page 9.

Cooling water connectors

G3/4" external thread

Tubing

3/4" inner dia. Tubing, compression-proof

IN

Cooling water inlet

OUT Cooling water outlet

Even high quality heat exchangers as they are installed

in our equipment can be damaged by unsuitable cooling

water.

The quality of the cooling water depends on the local

conditions.

The heat exchanger may become leaky due to corrosion

or it may become clogged due to particulate matter

Notice:

Flood

hazard!

In case the system to be cooled is located at a higher level than the recirculating

cooler, avoid possible flowback of bath liquid back when the unit is switched off.