Maintenance, Innovative fluid power, Installation and mounting 3.1. mounting position – HYDAC SK 600 User Manual

Page 2: Mounting, Connection, Venting, Safety precautions, Inspection and maintenance

INNOVATIVE FLUID POWER

50

PN#02068195 / 04.13 / ACU1102-1326

3. Installation and Mounting

3.1. Mounting Position

The piston accumulators can be mounted in any position. However,

the vertical mounting position with the gas valve at the top is

generally preferred.

Sufficient clearance must be left to mount and disconnect the

piston accumulator. In particular, an area of at least 150 x 150 x 150

mm must be left above the gas valve for fitting and operating the

charging and gauging unit.

3.2. Mounting

In accordance with the recommendations of the HYDAC brochure

“Mounting Components”, HYDAC piston accumulators must be

mounted vibration free using clamps and base brackets.

Note:

Mounting elements must never be welded to the

piston accumulator.

4. Connection

The connection of the accumulator to the system must be

stress free and torque free.

It must be possible to isolate the accumulator from the pressurized

hydraulic system.

5. Commissioning and Safety Precautions

5.1 Commissioning

Prior to connecting the accumulator to the pressurized system, the

precharge pressure should be rechecked. If the accumulator was

precharged at HYDAC the pressure level can be found on the label.

The level of the precharge pressure generally depends on the

following criteria:

•

type of system,

•

expected changes in operating temperature,

•

intended function of the accumulator.

The following precharge pressures are recommended:

for energy storage:

p

0,tmax

≤ P1 - 5 bar

p

0,tmin

≥ 2 bar

for volume compensation:

p

0

= static pressure of the system

Further information on the gas precharge pressures can be found in

the HYDAC accumulator brochure “Piston Accumulators”. Charging

and gauging of the precharge pressure is described in Point 6

“Inspection and Maintenance”.

Maintenance

5.2. Venting

Prior to commissioning, the accumulator must be vented on the oil

side. Then apply the maximum operating pressure to the complete

hydraulic system and check for leakages.

5.3. Safety Precautions

IMPORTANT!

Only use nitrogen to charge the accumulator, never

oxygen or compressed air

(risk of explosion)

.

If the pressure of the nitrogen bottle is higher than

the permissible operating pressure of the accumulator,

a pressure regulating valve must be fitted.

6. Inspection and Maintenance

On the whole, nitrogen losses on piston accumulators are very low.

However, it is advisable to check the precharge pressure p

0

at least

once during the first week following commissioning so that larger

nitrogen losses can be detected immediately. During the course of

the first two months check the precharge pressure every two weeks,

and thereafter every four weeks. If after this period no pressure

change is detected, an annual check of the nitrogen pressure is

sufficient.

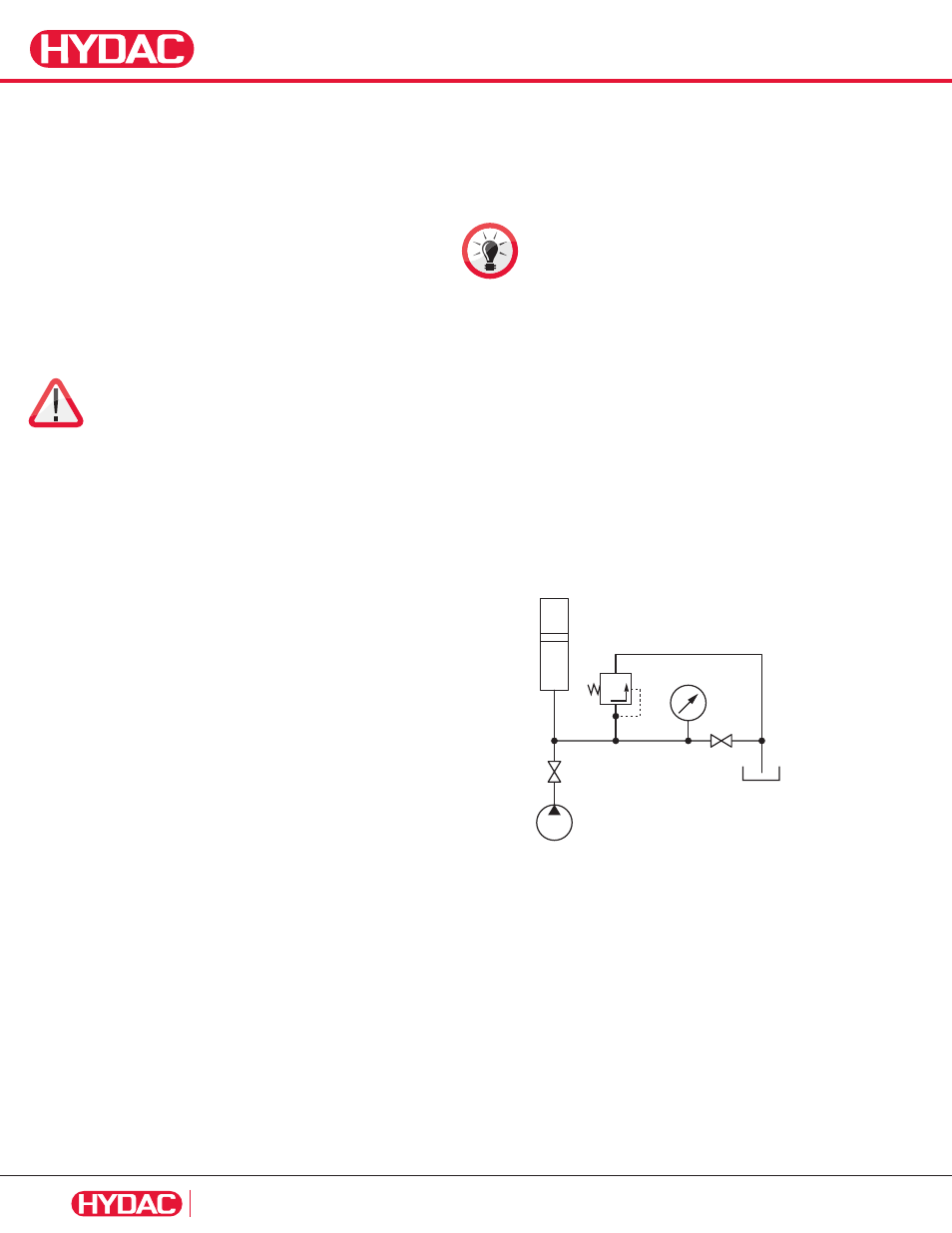

6.1. Checking the Nitrogen Pressure without

a Charging and Gauging Unit

In this case, as shown in the following drawing, a pressure gauge is

connected to a line which is directly connected to the accumulator.

E

A

Isolate the fully charged piston accumulator from the hydraulic

system by closing the shut off valve A. Slowly discharge the

accumulator on the fluid side via drain valve E. The pressure gauge

must be constantly monitored during this process. A slow, steady

pressure drop is displayed. The pressure only drops abruptly when

the accumulator has been completely discharged. The pressure

displayed before the drop corresponds to the precharge pressure

of the piston accumulator. If this pressure lies below the permissible

value, the charging procedure must be carried out, as described in

the following section.