Humanscale Float Assembly User Manual

Assembly instructions, Adjusting float, Troubleshooting float

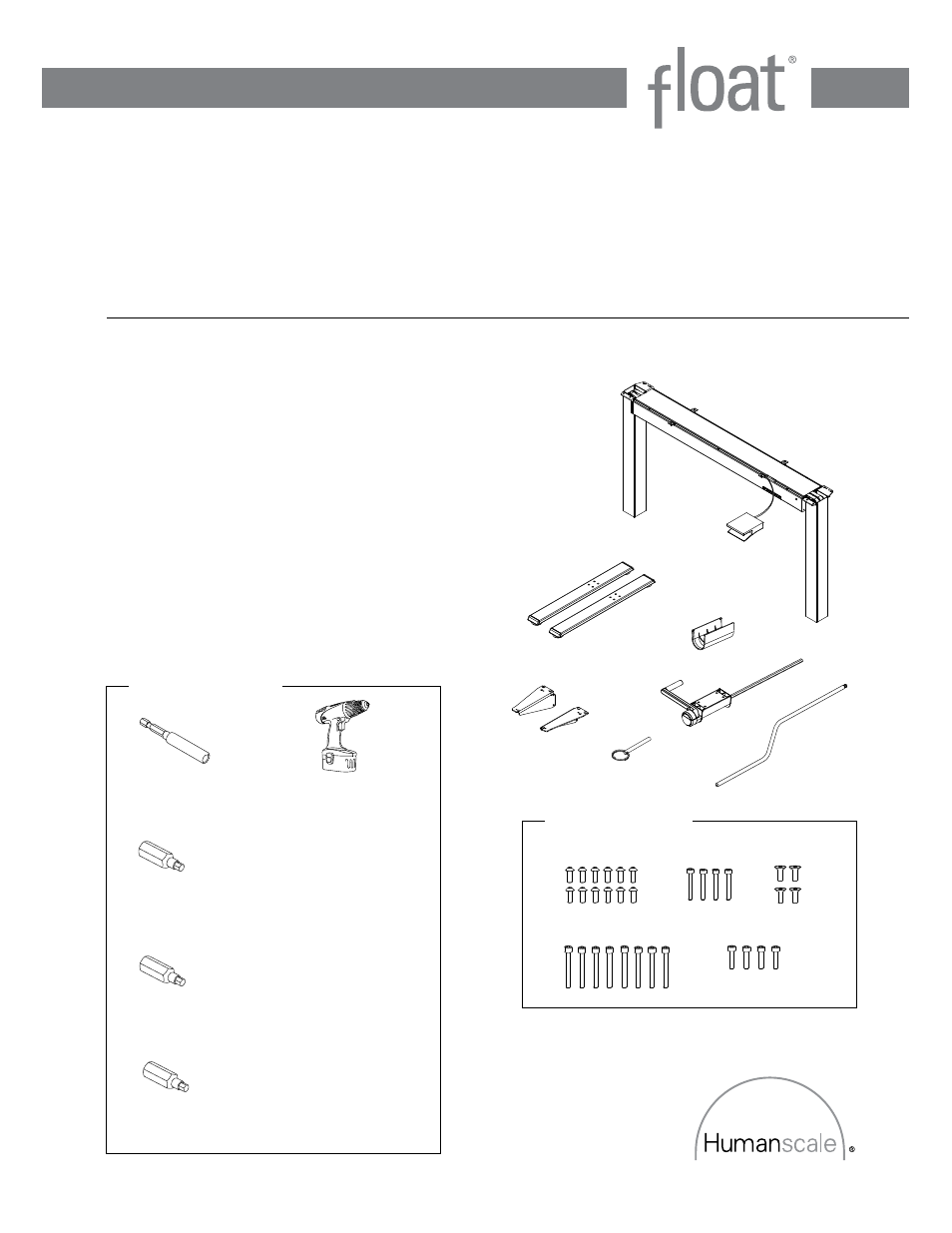

Power Drill

Extension Hex Drive

5/32 ” Hex Drive

3/16 ” Hex Drive

3 mm Hex Drive

Parts Required

A. (1) Float Table Base

B. (2) Float Wing Brackets

C. (2) Float Feet

D. (1) Mounted or Removable Spring Tension Adjuster

E. (1) Mounted Spring Tension Adjuster Plastic Housing

F. (12) M6 Short Machine Screws

G. (4) M5 Long Machine Screws

H. (4) M6 Short Flat Head Machine Screws

I. (8) M8 Long Machine Screws

J. (4) M5 Short Machine Screws

K. (1) Safety Leg Pin

A

B

C

E

Tools Required

Assembly Instructions

When using a Humanscale work surface

with pre-drilled metal inserts

F

I

G

H

Hardware Bag

J

D

K

Adjusting Float

Customer Service - 800 400 0625

www.humanscale.com

HSFI0713

If you are finding it difficult to raise and lower your Float, please check the barrel

adjuster behind the back of the Release Paddle (fig. A). The barrel adjuster

needs to be adjusted to increase the tension in the Release Paddle which will

allow for the Float to easily raise and lower. To make the required adjustment,

simply turn the barrel adjuster counterclockwise until you have between ¾” and

½” of metal thread showing. You will now find that the Release Paddle will

engage better and allow for the Float to be raised and lowered

Adding Weight to the Work Surface (fig. B)

As you begin to add more weight to the work surface, it will become more

difficult to raise and lower the table. The following steps explain how to adjust

your Float to make it easier to raise and lower:

1. Squeeze the Release Paddle and raise the work surface to its

maximum height (fully extended)

2. If using the Removable Spring Tension Adjuster, insert it into the hex

spigot on the center beam to the right of the min – max scale

3. Using either the Removable or Mounted Spring Tension Adjuster,

slowly begin to increase the tension by turning the Adjuster clockwise

4. You will start to see the red mark on the min – max scale move from the

min mark towards the max mark

5. Once you have adjusted your Float, bring the work surface back down

and try raising and lowering it a few times until it fluidly adjusts

6. If you need to make further adjustments, raise the Float to its

maximum height and follow these steps again

Removing Weight from the Work Surface (fig. C)

As you begin to remove weight from your work surface, you will notice that

Float will raise quickly and be difficult to lower. Simply follow the above instruc-

tions about adding weight to the work surface, but instead of turning the Adjust-

er clockwise, you will need to turn the Adjuster counterclockwise to release the

spring tension in the Float.

Float sits on four glides which can be adjusted to level the work surface, if the

floor is not level. These can be independently adjusted.

Important: Please be aware that your newly purchased Float will hold a maximum weight of 130 lbs. Please contact

Customer Service if you would like to find out more information about our Float heavy duty kit that will increase the

maximum weight loading from 130 lbs to 160 lbs.

If you are finding it difficult to raise and lower your Float, please check the barrel adjuster behind the back of the

Release Paddle (fig. A). The barrel adjuster needs to be adjusted to increase the tension in the Release Paddle which

will allow for the Float to raise and lower. To make the required adjustment, simply turn the barrel adjuster counter-

clockwise until you have between ¾” and ½” of metal thread showing. You will now find that the Release Paddle will

engage better and allow for the Float to be raised and lowered

If your Float is adjusted so that the min – max mark is at the ¾” position on the scale and the Float is still very difficult

to raise and lower, please contact Customer Service who will help you order a heavy duty Float kit that will allow for the

weight limit to be increased from 130 lbs to 160 lbs. This heavy duty kit will make the table easier to adjust with the

additional weight.

1

1

2

2

3

A

B

Troubleshooting Float

C

1