Grayhill DIP Switches: Thru-Hole 78B Series User Manual

Series 78b, Thru-hole dip switches

SERIES 78B

Right Angle Option

Thru-Hole DIP Switches

FEAtuRES

• Easy Access

• SPST Circuitry

• 2-10 and 12 positions available

• Sealed versions available

ApplIcAtIOnS

Telecommunications, computers

and peripherals, instruments and

controls.

SpEcIFIcAtIOnS

Mechanical

Mechanical life: 2,000 operations per

switch.

Operation temp: -40°C to + 85°C

Storage temp: -55°C to + 85°C

Vibration test: Per Method 204, Test Condition

B, 1 mS opening (10 mS allowed)

Shock test: MIL-STD-202F METHOD 213

Test Condition A, 1ms (10 allowed)

Electrical

Electrical life: 10,000 operations per switch

24VDC, 25mA.

non-Switching Rating: 100mA, 50VDC.

Switching rating: 150mA, 30DVC;

10mA, 50mVDC

contact Resistance: 30mΩ max. at initial.

Insulation Resistance: (at 100VDC) 5,000MΩ

min.

Dielectric Strength: 750VAC/1 minute.

capacitance: 2pF max.

Soldering and cleaning process

*For the most current soldering & cleaning processing

guidelines, reference Grayhill Dip Switch Processing

Information, Bulletin 1234

cleaning tape sealed products:

Passes immersion test using water/

detergent.

Acceptable solutions include 1-1-

1 trichlorethane, freon, (TF, TE, or TMS),

isopropyl

alcohol, detergent (140°F

maximum). Terpene

acceptable for Series 90

only.

Solutions which are not recommended

include acetone, methylene chloride, freon

TMC

. Pressure wash cleaning processes are

not recommended for tape seal switches.

Wave Soldering: Recommended solder

temperature: 500°F (260C) max 5 seconds.

Hand Soldering: Use

a soldering iron of

30 Watts or less, controlled at 608°F (320°

C) approximately 2 seconds while applying

solder.

cleaning: Tape sealed versions withstand

cleaning

processes.

Materials

contact Ball: Brass with gold plating over

nickel

terminals: Brass with gold plating over

nickel

nonconductive parts: Plastic UL94V-0

potting Material: Epoxy

Shorting Member (Ball): Brass, gold-plated

over nickel barrier.

protective cover: Polycarbonate.

tape Seal: Polyester film

tape Seal Integrity: Passes gross leak test

using 125°C flourinert for 20 seconds minimum.

Reference MIL-STD-202, Method 112.

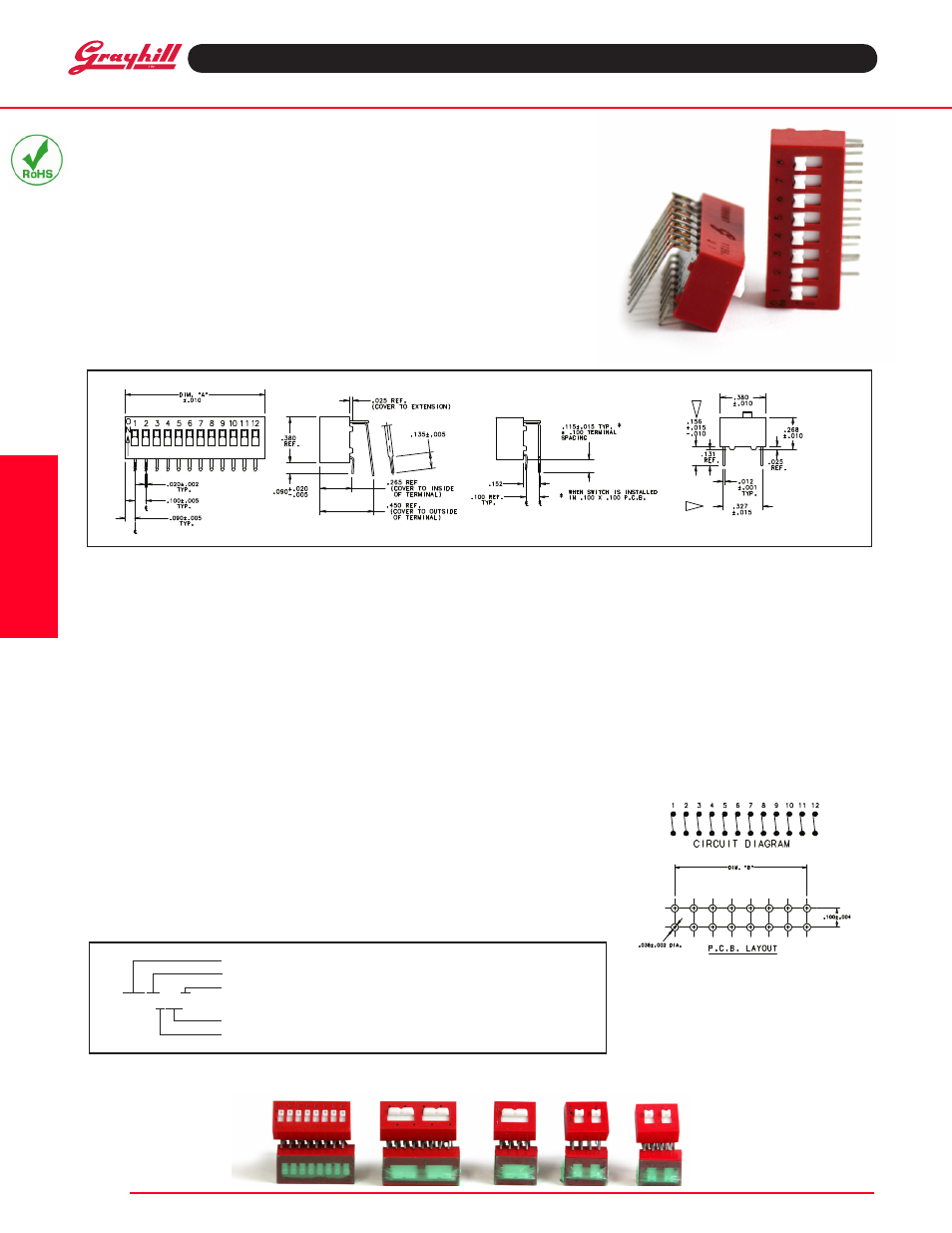

Series 78B DIMEnSIOnS

in inches (and millimeters)

Series 78B, 78F, 78G, 78H, 78J, 78K, 78RB

Styles available as right angle

number of positions 2 through 12

RoHS compliant

78B08SRAt

Right Angle

S= Top Tape Sealed, Blank=Unsealed

ORDERInG InFORMAtIOn

DIp

17

Right Angle Assemblies As Shipped

Right Angle Assemblies As Installed

Tape Sealed

78R

78K

78H

78F

78J

Grayhill, Inc. • 561 Hillgrove Avenue • LaGrange, Illinois 60525-5997 • USA • Phone: 708-354-1040 • Fax: 708-354-2820 • www.grayhill.com

DIP Switches