Snap action miniature pushbutton switches – Grayhill Pushbutton switches: Snap Action 38C Series User Manual

Page 5

Grayhill, Inc. • 561 Hillgrove Avenue • LaGrange, Illinois 60525-5997 • USA • Phone: 708-354-1040 • Fax: 708-354-2820 • www.grayhill.com

Pushbutton Switches

Snap Action Miniature Pushbutton Switches

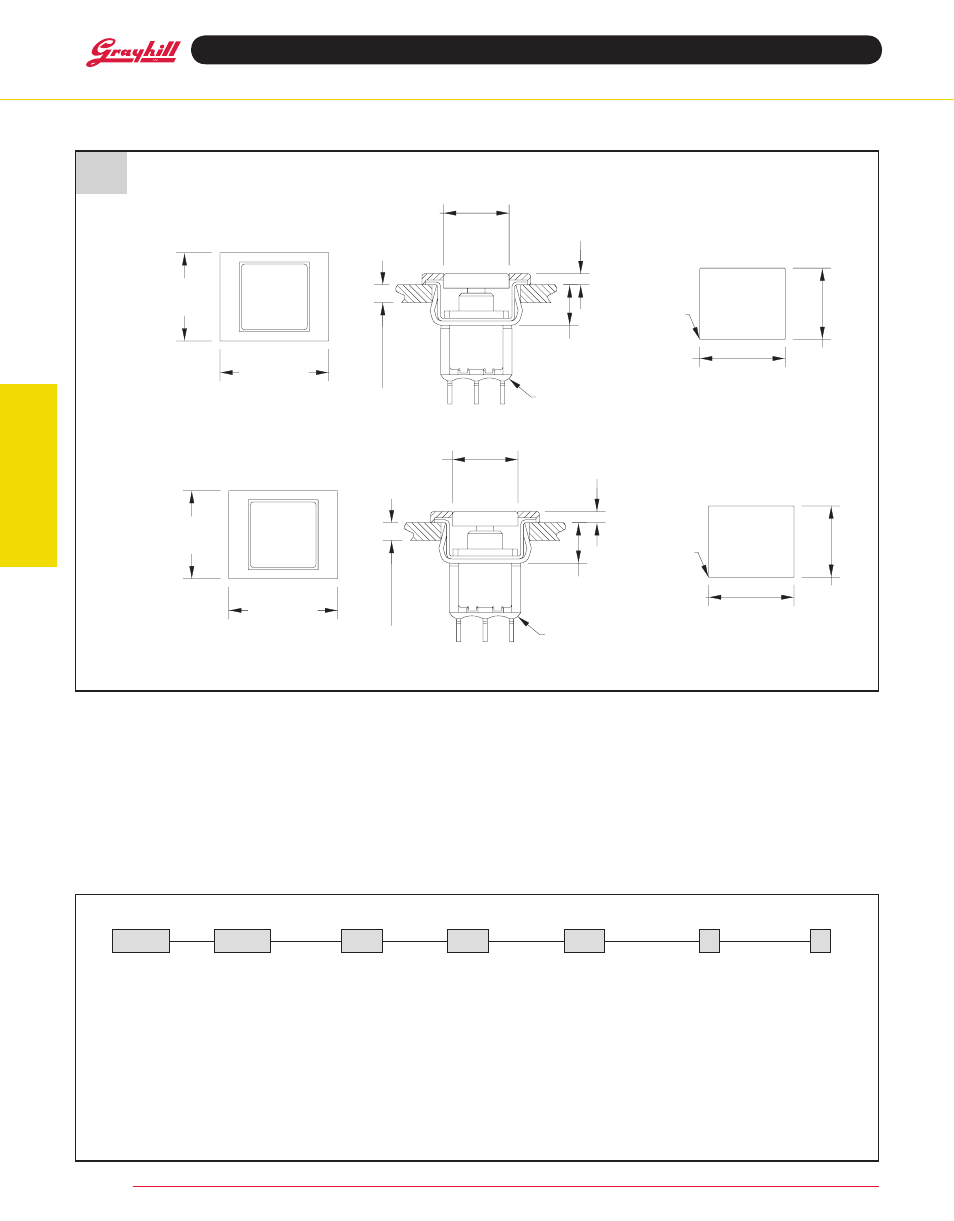

BuSHinG OPtiOnS

in inches (and millimeters)

FOR PANEL MOUNTING

aP3 Cap Only

aP4 Cap and Frame

SPeCiFiCatiOnS

ratinGS

Contact rating: Q & G option - 3A with re-

sistive load @ 125 VAC or 28 VDC; 1.5A with

resistive load @ 250 VAC. R option - 0.4 VA

max @ 20 Vmax (AC or DC)

electrical Life: 50,000 make-and-break

cycles at full load

travel: .050 ± .010

Contact resistance: 20 milliohms max. initial

@ 2-4 VDC, 100 mA

insulation resistance: 1,000 megaohms

minimum

dielectic Strength: 1,000 V RMS @ sea

level

Operating temperature: -30°C to 85°C

MateriaLS

Case: Diallyl phthalate (DAP) (UL94V-0)

Plunger: Glass filled nylon or glass filled

polyester

Bushing: Brass, nickel plated

Housing: Stainless steel

terminal/Switch Support: Brass, electrotin

plated

terminal Seal: Epoxy

OrderinG inFOrMatiOn

38C =

Miniature

Pushbutton

Switches

Options:

SP7, DP7

(see models

for

switching

positions)

Options:

Blank=std

as shown

in dwg

0 = 0.0

(Flush)

1 = .205

(5.02)

2 = .079

(2.00)

Options: M1,

M2, M3, M6,

M7, S2, S6

V2, V3, V4,

V5, W1, W2,

W3, W4 (see

termination

options)

R = Copper

alloy, gold

plate over

nickel plate.

Q = Copper

alloy, silver

plated

G=Gold

plate over

silver plate

T = Lead

Free and

RoHS

Compliant

SerieS MOdeL nO. PLunGer BuSHinG terMinatiOn COntaCt

SeaL

38C

SP7

B10

M1

Q

t

Options:

AP1, AP2,

AP3,

AP4, B10,

B11, B21,

B21 (see

bushing

options)

dPdt

SPdt

4 5

6

INCREASE TO .620/.625(15.75/15.88)

FOR .091/.125(2.32/3.18) THK. PANEL

PANEL LAYOUT

EPOXY SEAL

.763

(19.40)

.618

(15.70)

.460

(11.70)

.047 TO .125

(1.19 TO 3.18)

PANEL THICKNESS

.079

(2.00)

.284

(7.20)

.500

(12.74)

.600

(15.24)

R.005

(R.130)

1 2

3

INCREASE TO .620/.625(15.75/15.88)

FOR .091/.125(2.32/3.18) THK. PANEL

PANEL LAYOUT

EPOXY SEAL

.763

(19.40)

.618

(15.70)

.460

(11.70)

.047 TO .125

(1.19 TO 3.18)

PANEL THICKNESS

.079

(2.00)

.284

(7.20)

.500

(12.74)

.600

(15.24)

R.005

(R.130)