Table 12 – Georgia-Pacific APA Engineered Wood Construction Guide - Floors User Manual

Page 6

Floor Construction

ENGINEERED WOOD CONSTRUCTION GUIDE

■

FORM NO. E30V

■

© 2011 APA – THE ENGINEERED WOOD ASSOCIATION

■

33

If the floor has become wet during construction, it should be allowed to dry before application of finish floor, includ-

ing carpet, underlayment, hardwood flooring, ceramic tile, etc. After it is dry, the floor should be checked for flatness,

especially at joints.

When floor members are dry, make

sure fasteners are flush with or slightly

below surface of the STURD-I-FLOOR

panels just prior to installation of thin

floor coverings. Fasteners should be

set if green framing will present nail

popping problems upon drying. Do

not fill nail holes. To minimize the

chance of floor squeaks, installers

should press panels tightly onto joists

by standing on the panel over the joist

next to the nailing point. Fill and thor-

oughly sand edge joints (this step may

not be necessary under some carpet

and structural flooring products –

check recommendations of flooring

manufacturer). Fill any other damaged

or open areas, such as splits, and sand

all surface roughness. (Ensure fill com-

pound is fully cured before sanding

because it may continue to expand as

it cures.)

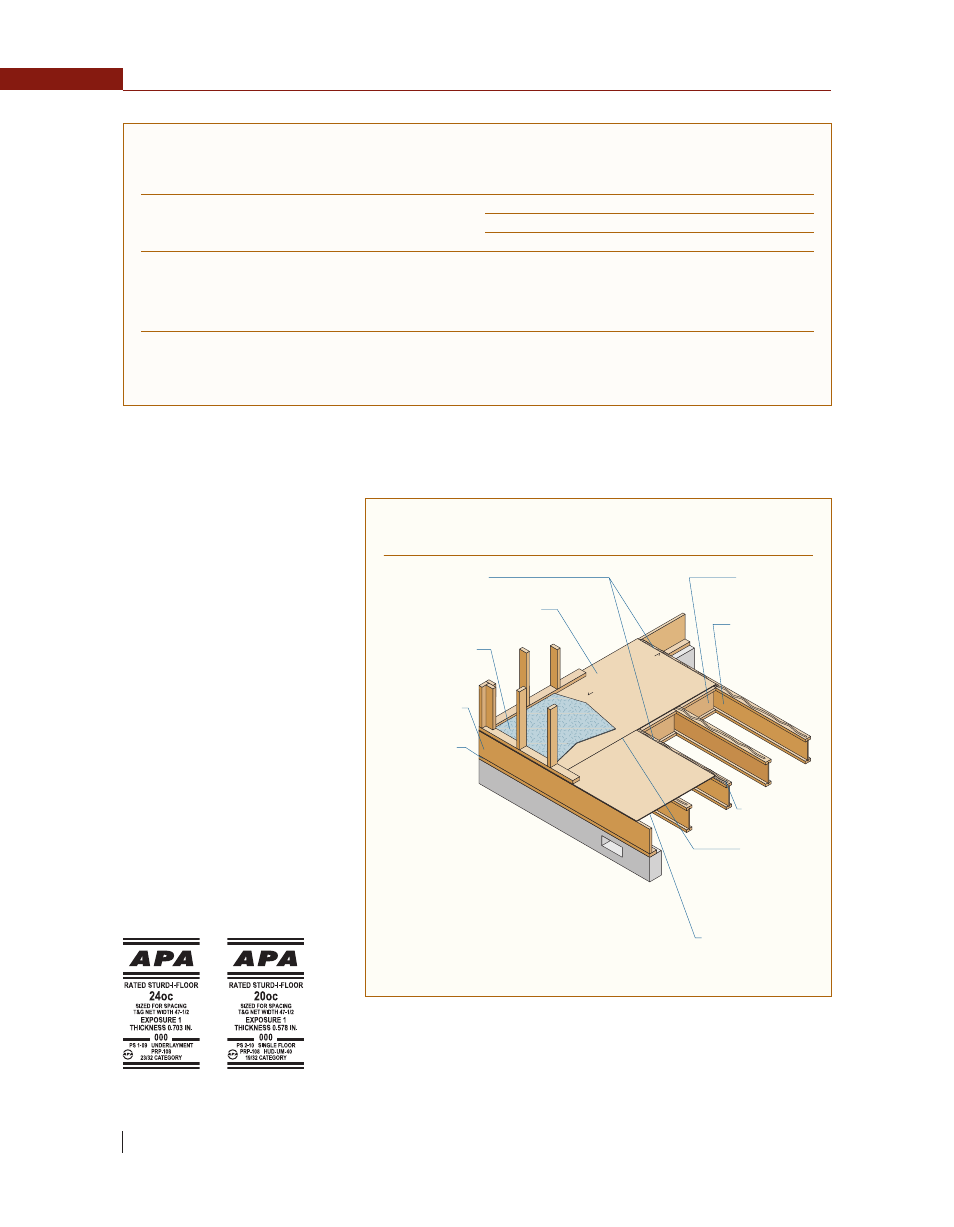

2x treated sill

Stagger end joints

APA RATED STURD-I-FLOOR

16, 20, 24 oc

Carpet and pad

2x rim joist or

APA Rim Board

1/8" spacing

is recommended

at all edge and end

joints unless otherwise

indicated by panel

manufacturer

Blocking with

square edge panels

2x joist, I-joists

or floor trusses –

16", 19.2", or

24" o.c.

Tongue-and-groove

edges (or 2" lumber

blocking between supports)

Notes:

1. Provide adequate

moisture control and

use ground cover vapor

retarder in crawl space.

Panels must be dry before

applying finish floor.

2. For buildings with wood or steel

framed walls, provide 3/4" temporary

expansion joints with separate floor framing

members and discontinuous wall plates over the joints,

at intervals that limit continuous floor areas to 80 feet

maximum in length or width, to allow for accumulated

expansion during construction in wet weather conditions.

FIGURE 1

APA RATED STURD-I-FLOOR 16, 20, AND 24 oc

Strength axis

Construction

adhesive optional

TABLE 12

RECOMMENDED UNIFORM FLOOR LIVE LOADS FOR APA RATED STURD-I-FLOOR

AND APA RATED SHEATHING WITH STRENGTH AXIS PERPENDICULAR TO SUPPORTS

(a)

Sturd-I-Floor

Span

Rating

Sheathing

Span

Rating

Minimum Panel

Performance

Category

Maximum

Span

(in.)

Allowable Live Loads (psf)

(b)

Joist Spacing (in.)

12

16

19.2

24

32

40

48

(c)

16 oc

20 oc

(e)

24 oc

32 oc

48 oc

24/16, 32/16

40/20

48/24

60/32

(f)

NA

7/16

(d)

19/32, 5/8

23/32, 3/4

7/8

1-3/32, 1-1/8

16

19.2

24

32

48

185

270

430

100

150

240

405

100

160

295

425

100

185

290

100

160

100

55

(a) Panels 24" or wider applied over two spans or more, dry; normal

load duration assumed.

(b) 10 psf dead load assumed. Live load deflection limit is l/360.

(c) 4x nominal or double 2x framing.

(d) 19/32 is minimum Performance Category of Rated Sturd-I-Floor.

(e) While Span Rating is shown as 20 oc, the actual joint spacing is

19.2 inches

(f) Check with supplier for availability.