I-joist installation – Georgia-Pacific Engineered Lumber User Manual

Page 3

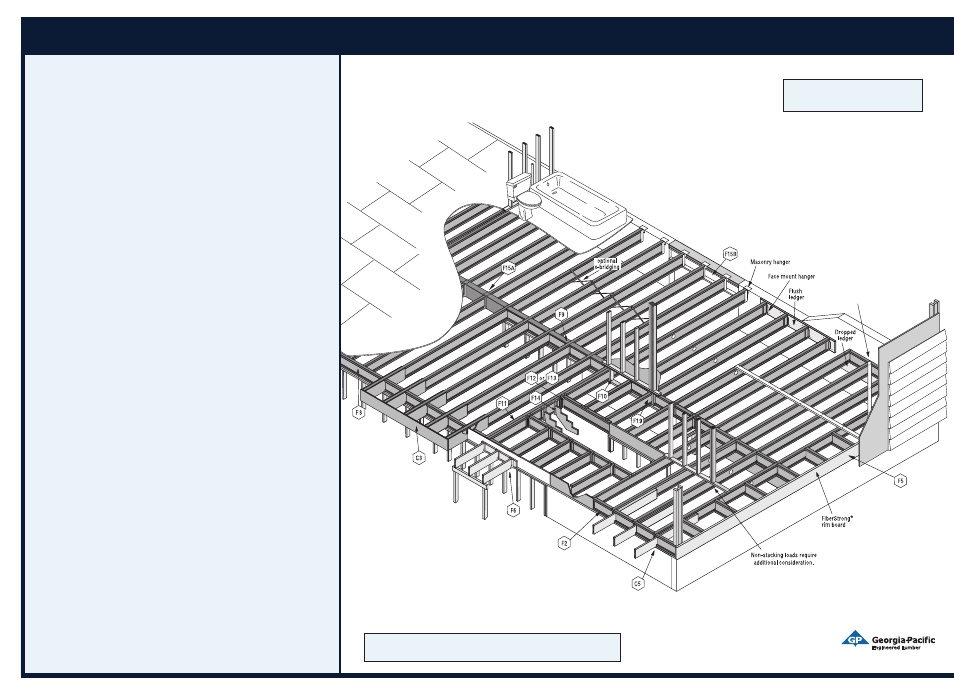

I-Joist Installation

1. Except for cutting to length, top and bottom flanges of Wood I Beam

™

I-joists shall

not be cut, drilled or notched.

2. End bearing length must be at least 1

3

⁄

4

(. Intermediate bearings of multiple span

joists shall be at least 3

1

⁄

2

(. Bearing on the edge of a single 2x ledger is not

adequate.

3. Engineered wood must not remain in direct contact with concrete or masonry

construction and shall be used in covered, dry use conditions only (moisture

content less than 16%).

4.

Wood I Beam I-joists must be restrained against rotation at the ends of joists by

use of rim joists, blocking panels, hangers, or cross bridging. To laterally support

cantilevered joists, blocking panels must also be installed over supports nearest

the cantilever.

5. Additionally, rim joists, rim boards, blocking panels or squash blocks must be

provided under all stacking exterior and interior bearing walls to transfer loads

from above to the wall or foundation below.

6.

Wood I Beam I-joists must be supported directly on walls, beams, girders, or in

hangers. Do not support I-joists by a non-structural ridge board or other

non-structural framing element. Do not toe nail I-joists into supports.

7. At cantilevered floor sections, the I-joists and floor framing (not the closure board)

must provide the primary support to walls above.

8. The top flanges of the Wood I Beam I-joists must be laterally supported at intervals

not exceeding 24( o.c. Plywood or OSB subfloor nailed to the top flange of a

Wood I Beam I-joist is adequate to provide lateral support. The top flanges

must be kept straight within

1

⁄

2

( of true alignment.

9.

Wood I Beam I-joists are produced without camber so either face of the flange can

be used as the top for sheathing attachment and the location of identifying stamps

does not affect performance. Vertically orient the largest dimension of the I-joist.

10. Fasteners, hangers or connectors for Wood I Beam framing either from or into

preservative or fire-retardant treated wood must be hot-dip galvanized, or stainless

steel, as required by code and the type of treatment.

11. Treating Wood I Beam I-joists is not recommended and voids the warranty, but

more importantly, presents a safety and performance concern.

12. When using hangers, seat I-joists firmly in hanger bottoms to minimize settlement.

Provide a gap between the I-joist end and the hanger per hanger manufacturer

recommendations.

13. Concentrated loads shall only be applied to the upper surface of the top flange, not

suspended from the bottom flange. Contact representative for exceptions.

14. Any fastening, resistance to uplift or member not specifically detailed is subject to

local approval.

15. Due to shrinkage, common framing lumber set on edge cannot be used as blocking

or rim boards. I-joist blocking panels or other engineered wood products – such as

APA Rim Board

®

– must be cut to fit between the I-joists, and an I-joist-compatible

depth selected.

16. Provide permanent lateral support of the bottom flange of all I-joists at interior

supports of multiple-span joists. Similarly, support the bottom flange of all

cantilevered I-joists at the end support next to the cantilever extension. In the

completed structure, the gypsum wallboard ceiling provides this lateral support.

Until the final finished ceiling is applied, temporary bracing or struts must be used.

17. If square-edge floor sheathing is used, sheathing edges must be supported between

I-joists with 2x4 blocking. Glue sheathing to the blocking to minimize squeaks.

Blocking is not required under structural finish flooring, such as wood strip flooring,

or if a separate underlayment layer is installed.

18. Nail spacing:

• Space nails installed to the flange’s top face in accordance with the applicable

building code requirements or approved building plans.

• If nails must be installed into the sides of LVL flanges, spacing shall not be closer

than 3 inches o.c. for 8d box or common nails, and 4 inches o.c. for 10d box or

common nails.

typical wood I beam floor framing and Construction details

NOTE: Except for cutting to length and

as shown in this or the design guide,

never cut or notch the flanges.

Temporary bracing–

Incomplete as shown. Refer to

the safety section of this guide for

complete bracing information, typ.

NOTE: Unlike with some conventional lumber sizes, Wood I Beam I-joists do

not require mid-span blocking or bridging for I-joist strength or stability.

Installation Guide