Torque potentiometer setting – General Machine Products 89300 AirStream Cable Blowing Machine User Manual

Page 37

Page 37 of 44

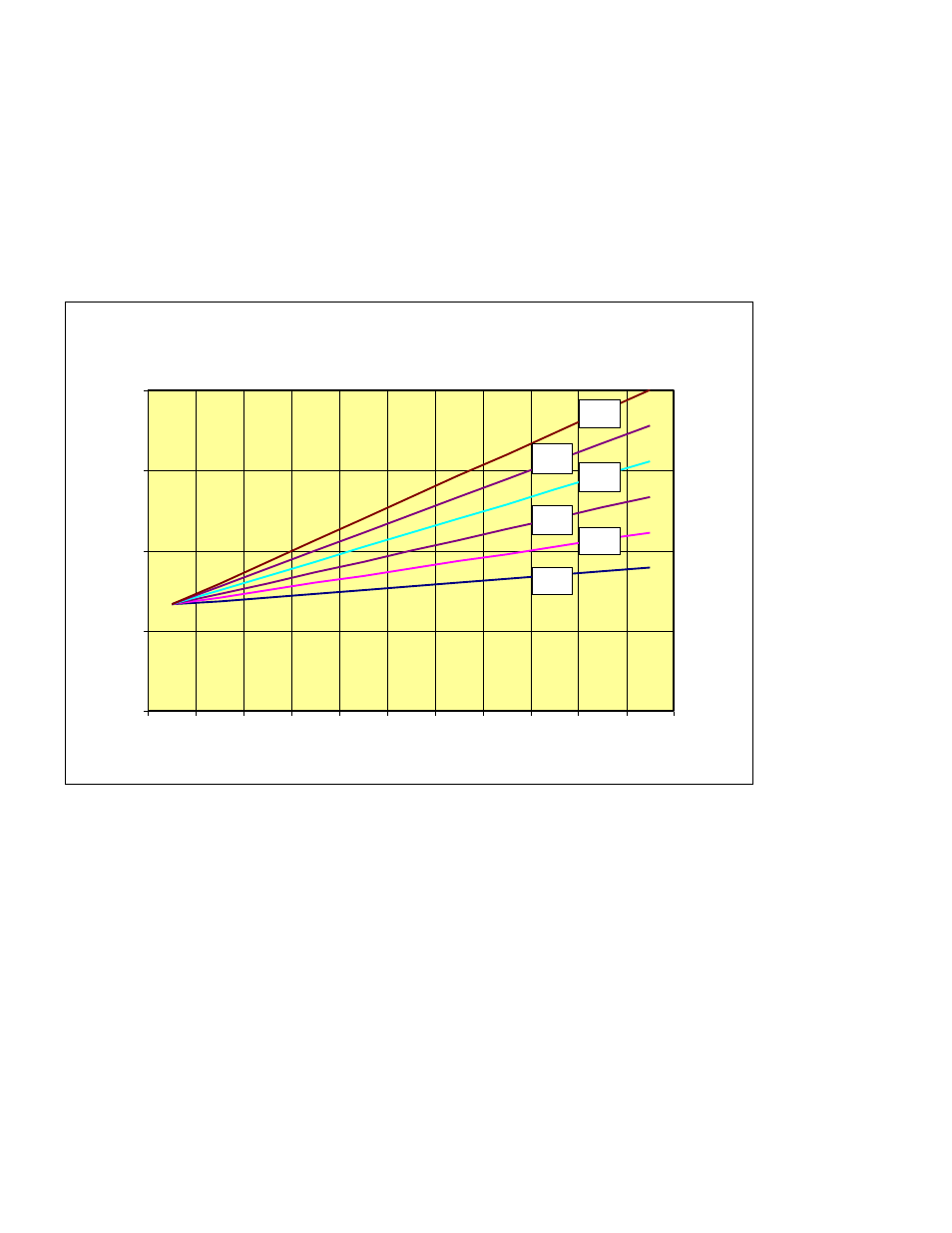

3 Referring to the chart below. The “x” axis (the bottom line) represents the coefficient of friction; 1 is very

low: 10 is very high. Look along this line from left to right. Pick a vertical line that is approximately the

value of the coefficient of friction. Look vertically upward along this line. It crosses a series of angled

lines, these lines are numbered U1, U2 etc. where the vertical line crosses the angled line with the U

figure determined from step 1 make a mark on the chart. Draw a horizontal line (parallel with the other

horizontal lines on the chart) from the marked point. Where this line crosses the “y” axis (the vertical

line at the extreme left hand of the chart), make a second mark on the chart. The height of this line

represents the % of maximum clockwise rotation of the torque control. If this line is very close to the

figure 0.5 marked on the “y” axis, set the torque control potentiometer approximately one half of the

way around its maximum travel etc.

There is an alternative way of arriving at the appropriate setting for the torque control potentiometer. Do the

following.

Select a sample of the cable to be used. Pass the cable through the machine as described in the manual.

Feed the cable into the beginning of a length of sample tube (say 5 meters long). Seal the open end of the

tube. Position the torque control potentiometer at the position determined by the recommendations in this

Appendix, Start the machine. Drive the cable hard into the sealed end of the sample length of tube. The

rollers will stop turning, this is because the torque limit has been reached. Repeat this procedure, each time

turning the torque potentiometer a little further clockwise. Eventually, the cable will buckle. The setting of the

torque control potentiometer is now a little too far clockwise. Turn it back (counter clockwise) a little. This is

the optimum setting.

Torque potentiometer setting

0

0.25

0.5

0.75

1

1

10

Coeff of friction

%

o

f

m

a

x

im

u

m

r

o

ta

ti

o

n

(

c

lo

c

k

w

is

e

)

U1

U2

U3

U4

U5

U6