Speed control schematic diagrams: (cont.), Troubleshooting – Fuelab 42402 Prodigy Fuel Pump High Power EFI In-Line User Manual

Page 4

for proper wiring and installation.

110020274-1, Rev C Page 4 of 6

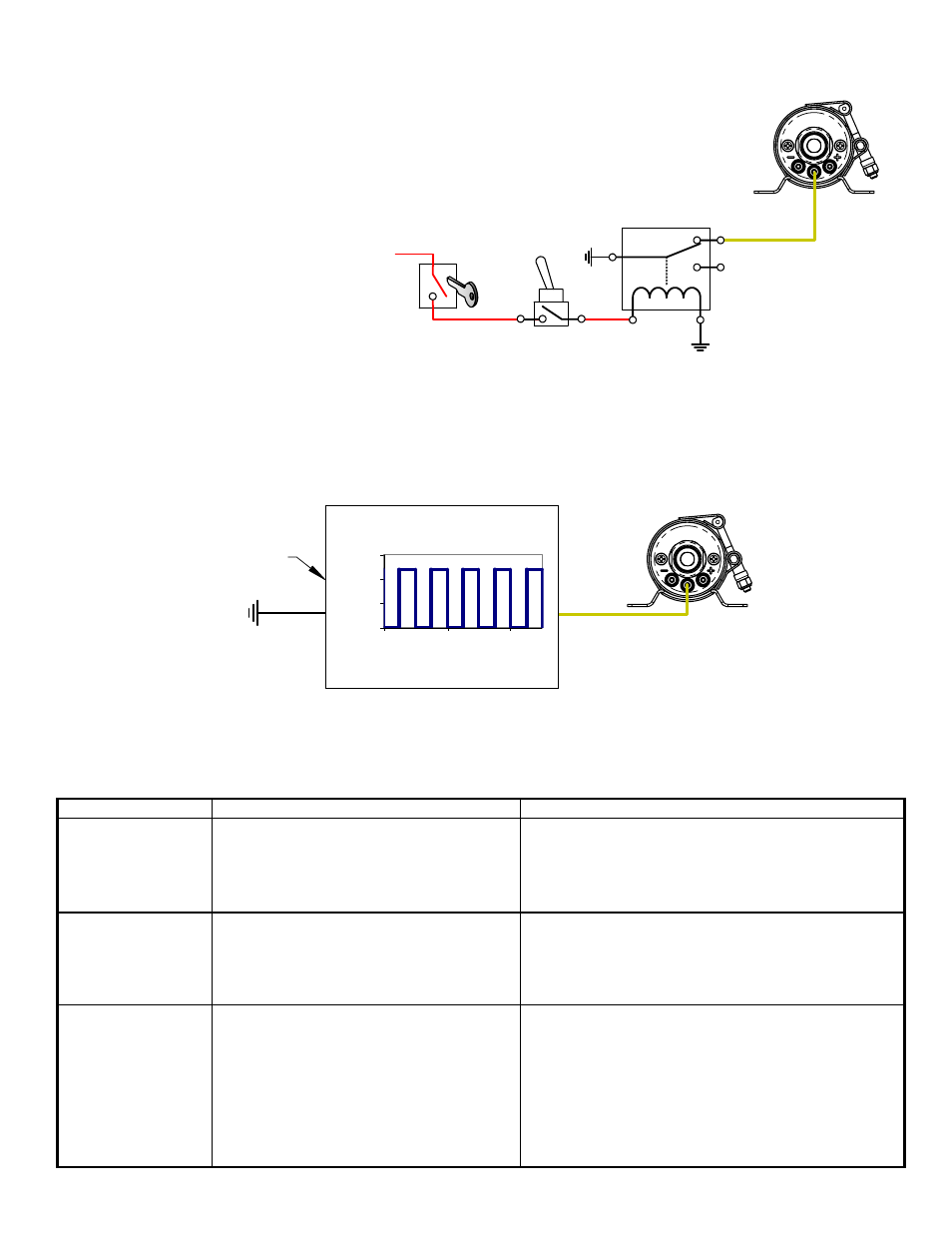

SPEED CONTROL SCHEMATIC DIAGRAMS: (cont.)

recommended during long periods of

low engine fuel demand conditions to

Example 4: Switch to Power Speed Changing

example. Reduced speed is

avoid fuel system heat build-up.

When the switching action is in reverse

to what can be used as shown Example 3,

such as some pressure switches, the

action can be reversed through the use

of a Single Pole Dual Throw (SPDT) relay

as shown to the right. Current draw through

this circuit is extremly low (much less

than 1 amp), so a very low current

rating for this 12 volt relay and switch

can be used. Use the diagram to the

right as a guide to properly wire this

Refer to above Example 5, for use with the Fuelab Electronic Fuel Pressure Regulator, Models 52901 and 52902,

that creates its own pulsed signal. These regulators automatically control the fuel pump, without the use of switching

means or other components such as described in examples 2 and 3. Refer to instructions for the Electronic Regulator,

TROUBLESHOOTING:

ELECTRONIC DEVICE SUCH

AS AFTERMARKET ENGINE

MANAGEMENT MODULE.

Input Signal

0

5

10

15

0

2

4

Time (sec X10

-3

)

Vo

lt

a

g

e

(

v

)

Peak Voltage shown at 12V,

typically this value is actually

peak vehicle voltage.

Square Wave Signal, at

Recommended frequency: 500-

1500Hz, (shown at 50% duty cycle)

Example 5: Variable Speed

Devices such as an aftermarket ECM can create a pulsed signal (“pulling” voltage to ground at a given frequency). This

signal has a characteristic of dwell time, which is a ratio of on-time vs. off-time (in other words, the amount of time the signal

is at vehicle voltage vs. at zero voltage). This difference in dwell time percentage will enable the fuel pump to operate at

various speeds or flow rate. A graph demonstrating an example signal created by such a device is shown below. The

example signal is at 50% duty cycle, whereas the amount time that the signal is at vehicle voltage is equal to the amount of

time at zero volts. When duty cycle is between 0-20%, the fuel pump is turned off. A duty cycle between 20%-90% will be

variable speed between minimum and maximum speeds, while duty cycles between 90% and 100% are maximum Speed.

IGNITION

SWITCH

From

+12V

Source

SPDT RELAY

(1+A RATING)

C

NO

NC

PUMP OPERATES

AT REDUCED

SPEED WITH

SWITCH POSITION

SHOWN (OPEN).

Problem Possible

Cause

Possible

Solution

Not operating or

slight “clicking”

sound when turned

on.

• Faulty fuel pump relay.

• Faulty, dirty or corroded terminals

or improperly sized wire.

• Debris from tank or plumbing

lodged inside pump.

Check voltage to fuel pump, at power terminals. If

voltage is steady and consistent (within ½ Volt of

battery) then contact Fuelab for repair. If voltage is

inconsistent as described, repair or replace electrical

components as required.

Speed of pump

changes up and

down very

noticeably and

erratically.

• Incorrect wiring of speed control

as specified in wiring Examples 1

through 5.

• Loose terminal or wiring of speed

control circuit.

Unhook speed control wiring from yellow terminal of

pump. Turn on pump; if operation is consistent, then

repair or replace components as required.

Loss of fuel

pressure or erratic

pressure pulsation

after several

minutes of

operation.

• Cavitation (vapor lock) due to

overheating or restricted inlet.

Check temperature of pump right after failure. If

pump is hot to touch (cannot leave hand on pump

due to it being too hot), then follow proper speed

control wiring example, or look for other sources of

heat such as exhaust. If pump is not hot to the touch,

check for inlet restrictions such as improperly vented

tank, kinks in the fuel line, or too small of plumbing

for application. Contact Fuelab, as pump may be

damaged due to improper operating condition.