Fuelab 42402 Prodigy Fuel Pump High Power EFI In-Line User Manual

Page 3

Fuelab Model:

42402-c (-sp)

FUEL PUMP

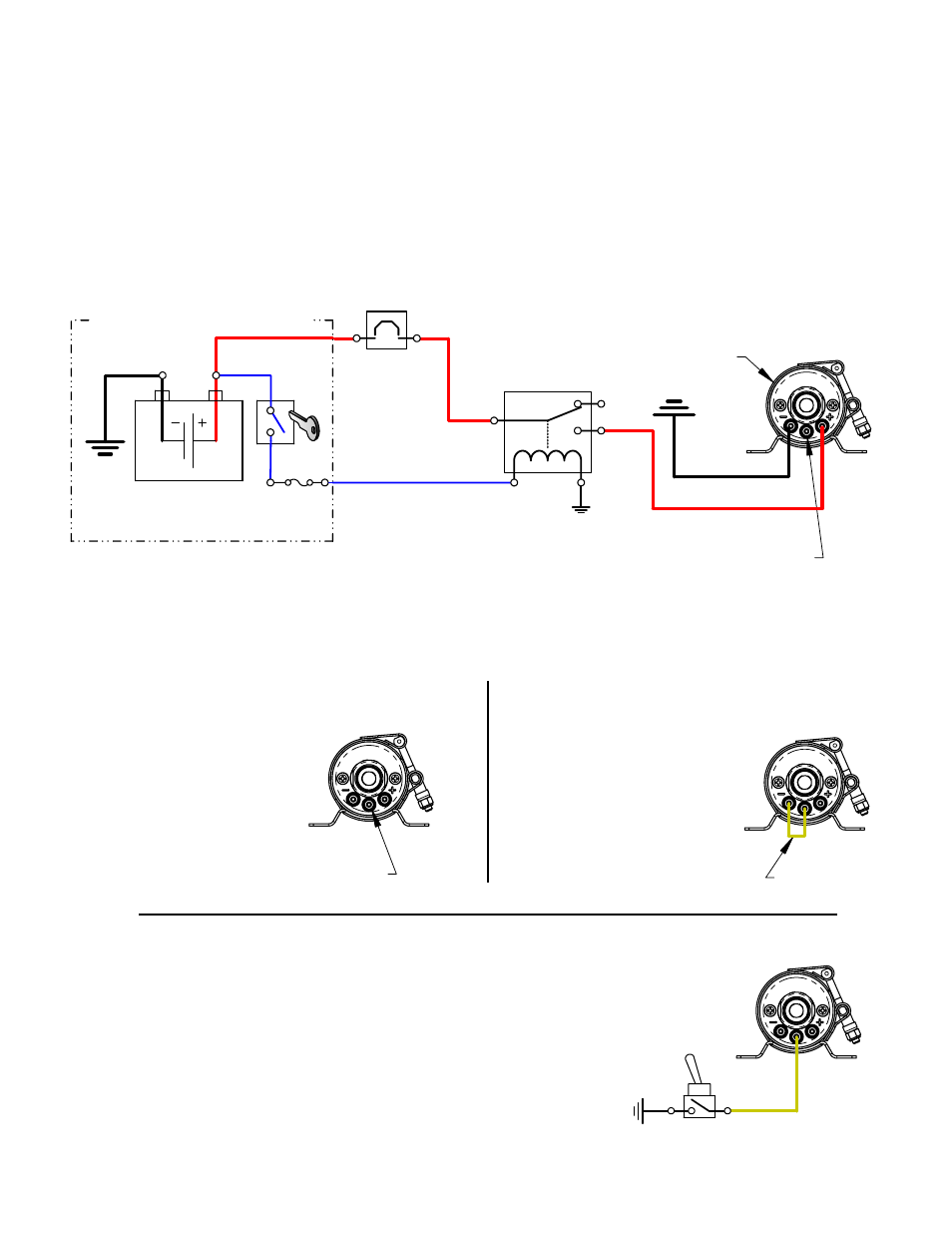

(16-20ga) Device or Circuit can be used as shown below,

for proper operation.See Speed Control Schematic Diagrams

for wiring of speed control (Yellow Lug).

PUMP OPERATES

AT MAXIMUM SPEED

WITH SWITCH POSITION

SHOWN (OPEN).

NO JUMPER WIRE

OR DEVICE

Example 3: Switch to Ground Speed Changing

110020274-1, Rev C Page 3 of 6

(Electrical components shown are not supplied with Fuel Pump)

MAIN WIRING SCHEMATIC DIAGRAM:

SPEED CONTROL SCHEMATIC DIAGRAMS:

and reduced speed.

switching between maximum

See Examples 3 and 4 for

pulsed signal may also be used to control pump speed. See examples below for a method suitable for your application.

Example 1: Continuous Maximum Speed

speed control terminal has greater than 2.5V (Approx), the mode of operation is in continuous maximum speed. A

terminal has less than 1/4V (Approx) applied to it, the mode of operation is in continuous reduced speed. When the

The speed control terminal (Yellow Center Lug) can have voltage or a signal applied to it. When the speed control

considered continuous duty.

this mode of operation is

adequate for application. Using

flow rate at reduced speed is

Yellow Lug. Use Example 2 if the

negative terminal (Black Lug) and

See schematic, attach wire between

shown on the pump certification.

electrical switching of fuel pump. Consult appropriate racing guidelines, rules and regulations.

Attach no wiring to speed control terminal, to operate

demand for extended periods.

Example 2: Continuous Reduced Speed

operating with low engine

maximum speed only while

cooling may be required using

damage fuel pump. Additional

heating and therefore may

maximum speed may cause over-

interval use. Use in continuous

specific applications, or short

Speed”. Use Example 1 for racing

Pump Certification as “Maximum

curve was recorded as shown on the

pump at continuous maximum speed. The performance

Attach a jumper wire as shown below, to operate

pump at continuous reduced speed. The reduced

speed is preset, with the performance curve

Reference Sheet 3 and 4 for schematic wiring diagram examples. Use electrical components as described including

electrical connectors that are appropriate for the operating environment of the fuel system, whether its use in street,

racing, or marine applications. Electrical connectors for the power leads must be capable of high current draw,

note all connections, wire and component rating requirements herein. Solder and use shrink wrap for wire splices

for extra reliability. Use of a check valve in fuel system as shown in plumbing diagram will maintain fuel pressure at

normal levels during engine starting and may be required depending on the wiring of main relay control circuit.

(OEM and some aftermarket ECMs have fuel pump relay control outputs that will turn off fuel pump during engine

starting, requiring check valve use.) If the fuel pressure does not maintain during engine starting, ensure fuel pump

is energized while starting. Main wiring schematic diagram, below shows the control of relay by ignition switch.

This source can be changed as described, or by a toggle switch. Some forms of racing have specific rules regarding

Electrical Planning Notes:

Attach switch and wiring as shown to the right, to operate pump at

continuous maximum speed while switch is in the open position

(position as shown in diagram). When the switch is in the closed position

(on), the pump will operate in reduced speed mode. To reverse the

desired switch action, refer to Example 4. Switch type can be a relay or

switching based on pressure or other means. Current draw through this

circuit is extremely low (much less than 1 amp), so a very low current rating

for this switch can be used. Use the diagram to the right as a guide to

properly wire this example. Reduced speed is recommended during long

periods of low engine fuel demand conditions to avoid fuel system heat

build-up.

JUMPER WIRE

CIRCUIT

BREAKER

or FUSE

(30A-40A)

C

NO

NC

FUEL PUMP

POWER RELAY

(30+A RATING)

(10-12ga)

(10-12ga)

VEHICLE BATTERY

(12-16 Volt System)

VEHICLE ELECTRICAL SYSTEM

IGNITION

SWITCH

or ECM

(10-

12ga)

(16-20ga)

FUSED

CIRCUIT

(1-5A)