Enerpac V-Series User Manual

Page 3

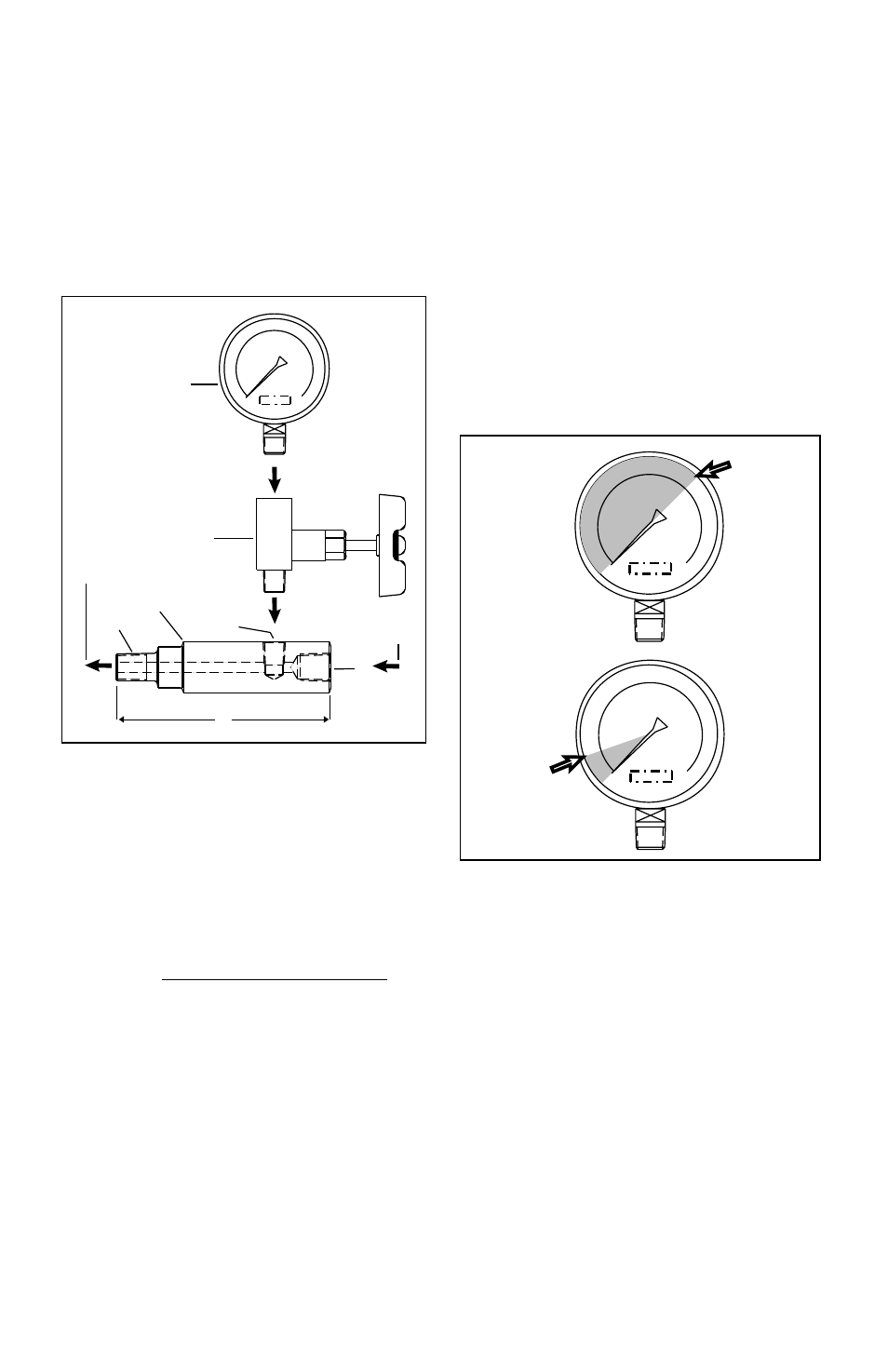

complete removal from the system or by

installation of a shut-off valve between the

gauge and the high-pressure line.

Should the hydraulic gauge be left in operation

continuously, the calibration of the gauge may

be greatly affected, requiring recalibration or

complete replacement. Shut-off valves are

recommended as added protection for any

hydraulic gauge that may be subjected to high

cycle rates or pressure fluctuations.

(1) Gauge

(2) Shut-off Valve

(3) Gauge Adaptor

4.0 INSTALLATION

NOTE: When making hydraulic connections,

use high quality sealing compound only on the

threads of the male NPT fittings. If you use

Teflon tape, do not tape the first thread. Use

tape sparingly. Loose Teflon tape in your pump

or cylinder can cause malfunctions and

damage. Wrap tape so that it tightens upon

assembly (clockwise with the threads facing

you). Install your hydraulic gauge where it is

easily readable but well protected against

damage from external sources.

1. Remove the hydraulic oil outlet plug(s) from

your pump.

2. Apply sealant (or Teflon tape) to male NPT

threads. Make connections as pictured

above. When tightening hydraulic

connections and fittings, use the proper

open-end wrenches. Do not use crescent

or pipe wrenches, as they may damage the

high-pressure fittings.

5.0 OPERATION

The gauge should be operated at pressures

which do not normally exceed 75% of full

scale.

Using the gauge to read less than 10% of the

full scale can result in an erroneous reading.

IMPORTANT: The gauge should be checked

for accuracy on a periodic basis, especially

when the pressure measurement is critical and

a gauge failure or inaccuracy will create a

hazard to personnel or property.

6.0 REPAIR AND SERVICE INFORMATION

Enerpac gauges are precalibrated by the

factory to within ±1% and ±1

1/

2

% of the full

scale. For recalibration, please refer to your

local phone or business directory. For warranty

and/or repair service, send your gauge to the

nearest Enerpac Service Center.

6.1 Glycerin Gauge Maintenance

For maintenance, please contact your nearest

authorized Enerpac Service Center. The

procedure for filling the glycerin gauge is

covered in Enerpac's Instruction Sheet, L2561.

75%

10%

A

B

C

(1)

(2)

(3)

L

3

Hose or

coupler

Pump

outlet port