Enerpac JH-Series User Manual

Page 5

MAINTENANCE

1. Before storing, inspect and clean the jack.

2. Close the air vent on 30 - 100 Ton models.

3. Store jack upright to protect the seals.

4. Periodically lubricate the jack pump beam.

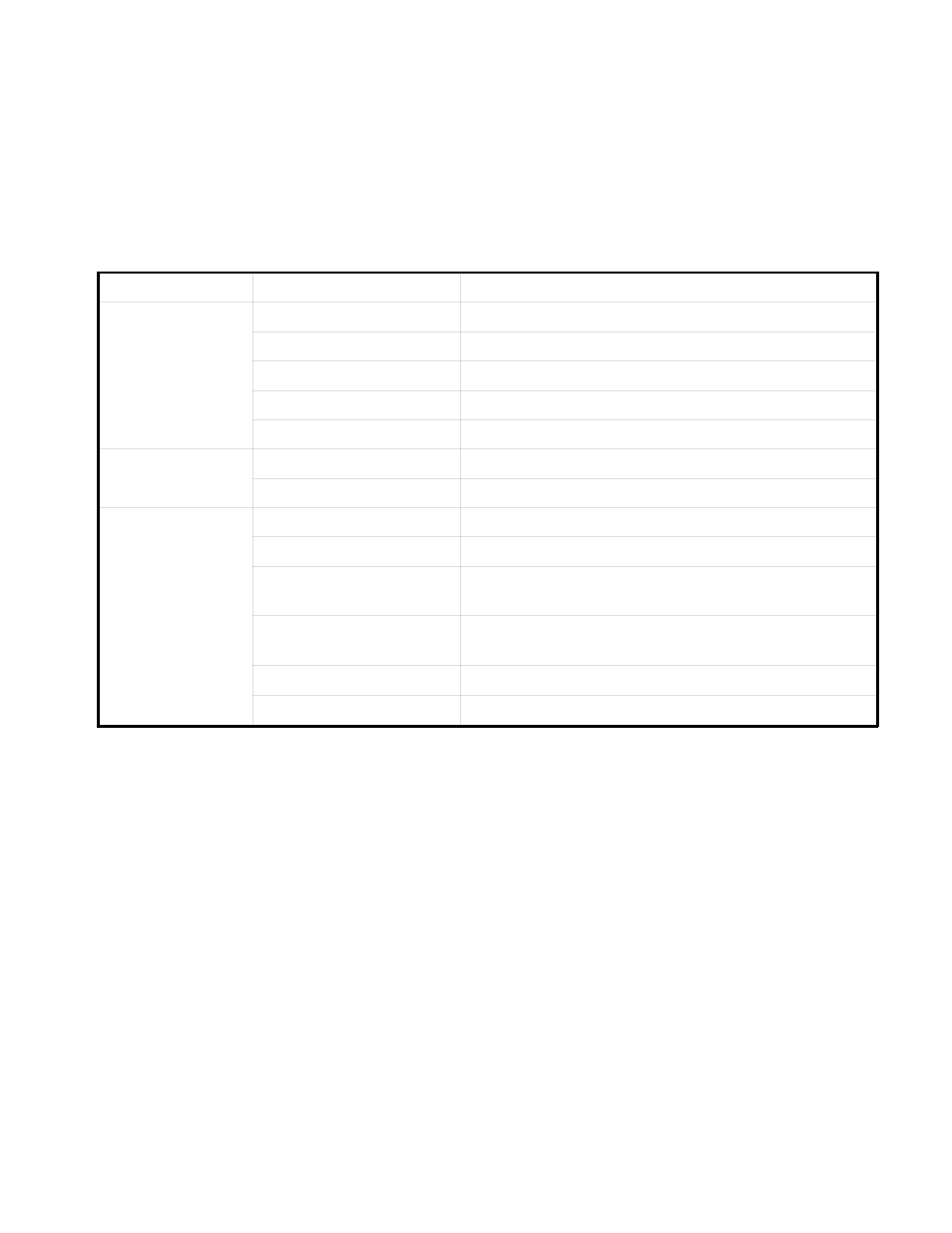

TROUBLESHOOTING

The following is intended as an aid in determining if a problem exists. DO NOT

disassemble the jack. For repair service, contact the Authorized Enerpac Service Center

in your area.

Problem

Possible Cause

Solution

Jack will not rise,

rises part way, or

rises in spurts.

Load is too heavy

Do not attempt to lift more than rated capacity.

Release valve open.

Close release valve.

Low fluid level.

Add fluid. See page 3.

Air in system.

Remove air as directed on page 3.

Plunger binding.

Have jack serviced by a qualified hydraulic technician.

Jack rises, but loses

pressure.

Load is too heavy.

Do not attempt to lift more than rated capacity.

Plunger seal leaking.

Have jack serviced by a qualified hydraulic technician.

Plunger will not

retract.

No load on the plunger.

Put weight on the plunger to help it retract.

Release valve closed.

Open the release valve slowly. See "Lowering the Load".

Air vent closed

(on 30 - 100 Ton models)

Open air vent valve.

Reservoir is over-filled.

With jack in the upright position and no load, remove fill plug

and allow oil to drain out of fill hole.

Worn or damaged seals.

Have jack serviced by a qualified hydraulic technician.

Plunger damage.

Have jack serviced by a qualified hydraulic technician.

5