Enerpac JH-Series User Manual

Page 3

SAFETY INFORMATION

(continued)

a

WARNING

DO NOT lift a load which exceeds the

capacity of the jack. The load rating is

marked on the jack nameplate.

a

WARNING

If the jack is subjected to abnormal or shock loads, it should be

inspected immediately by a qualified hydraulic technician.

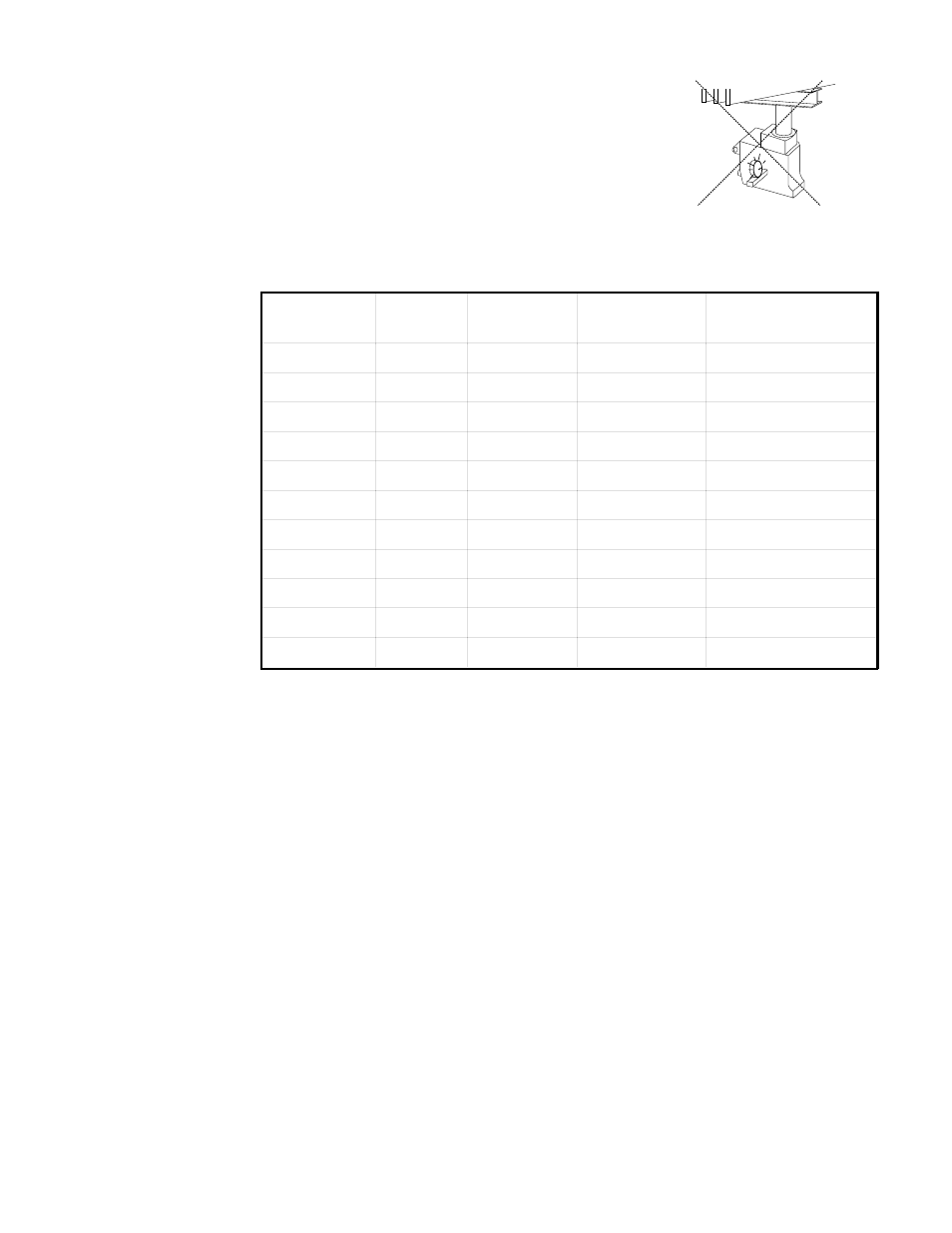

SPECIFICATIONS

Model No.

Capacity

Tons

Stroke

in (cm)

Effective Area

in

2

(cm

2

)

Collapsed Height

in (cm)

JH1.5

1.5

5.19 (13.2)

0.69 (4.45)

7.50 (19.1)

JHL1.5

1.5

18.00 (45.72)

0.69 (4.45)

21.72 (55.17)

JH3

3

5.88 (14.9)

1.23 (7.94)

8.75 (22.2)

JHL3

3

20.00 (50.80)

1.23 (7.94)

26.31 (66.83)

JH5

5

6.25 (15.9)

1.87 (12.1)

9.50 (24.1)

JH8

8

6.25 (15.9)

1.87 (12.1)

9.50 (24.1)

JH12

12

5.13 (13.0)

3.28 (21.2)

8.88 (22.6)

JH20

20

6.50 (16.5)

5.16 (33.3)

11.00 (27.94)

JH306

30

6.13 (16.0)

5.94 (38.3)

10.00 (25.40)

JH506

50

6.09 (15.5)

9.62 (62.1)

10.25 (26.04)

JH1006

100

6.06 (15.4)

20.63 (133.1)

11.31 (28.73)

INSTALLATION

Adding Fluid

a

WARNING

Before adding fluid, make sure the plunger is fully retracted, or the

system will contain more fluid than the reservoir can hold.

1. Use wrench end of jack handle to open release valve by turning counter-clockwise.

2. Place jack on its side with fill plug facing up. Remove fill plug.

3. Slowly add Enerpac hydraulic fluid. Do not fill reservoir completely. Fluid level

should be below fill plug when jack is upright.

4. Stand jack upright, allowing excess fluid to run out of fill plug hole. Replace fill plug.

Clean off excess fluid.

Removing Air

1. On 30 - 100 Ton models, open air vent.

2. Use wrench end of jack handle to open release valve by turning counter-clockwise.

3. Insert jack handle into jack pump beam and rapidly pump the handle.

4. Use wrench end of jack handle to close release valve by turning clockwise.

5. If jack operation is not smooth, repeat the air removal procedure.

3