Media installation, Using narrow width or thick media, Unusually shaped media adjustment – Dascom 7010 Quick Start Guide User Manual

Page 2: Windows, Drivers, Thermal transfer ribbon installation, Printer configuration, Peel & rewind mode

Rewinder spool

Media (liner)

Rewinder spool

Large blue-head open lever

Sensor arm

open lever

"Media": Usually a roll of labels,

card tickets or tags

Media Holder Assembly:

Slide the Media holder

guide on to the Media

holder bar

( f )

(e)

1

2

Ribbon holders

Paper core

Unused full ribbon

Media guide arm

(in raised position)

Media width adjustment knob

Media thickness adjustment screw

Media thickness

check window

Media width check window

(1)

(2)

(3)

3

Media Installation

6

Using narrow width or thick media

7

For non-standard media sizes and shapes, you may need to adjust the media sensors. The adjustable sensor is standard fitment.

a. Measure your required detection position beforehand,

using the scale on the upper guide rail.

b. Load media in to the printer as described

elsewhere. Ensure the media guide arm is lowered

and clicked down, but leave the printhead

mechanism open.

c. By rotating the adjustment knob, move the

adjustable sensor to the required position. The

yellow mark visible through the adjustment

window should be used to align the sensor with

the required position across the media.

Unusually Shaped Media Adjustment

8

Printer Driver Installation

If the drivers are not included with the printer, you can download the

latest version free-of-charge from our web site, details of which are on

the back of this Quick Start Guide.

Under the latest versions of Windows

¨

, the computer will often

automatically detect the presence of the printer. Therefore it is

advisable to download the drivers from our web site before installing

the printer so the files are ready for installation:

www.dascom.com

During installation of the printer driver, the computer may ask you to

select the printer required.

You will need to click on the "Have Disk..." box then tell the computer

the location of the driver files on your CD ROM.

Your supplier will assist you with the correct drivers and software

which are compatible with your particular computer system if you are

not using Windows

¨

.

Windows

¨

is a trademark of Microsoft

¨

Corporation.

Windows

®

Drivers

4

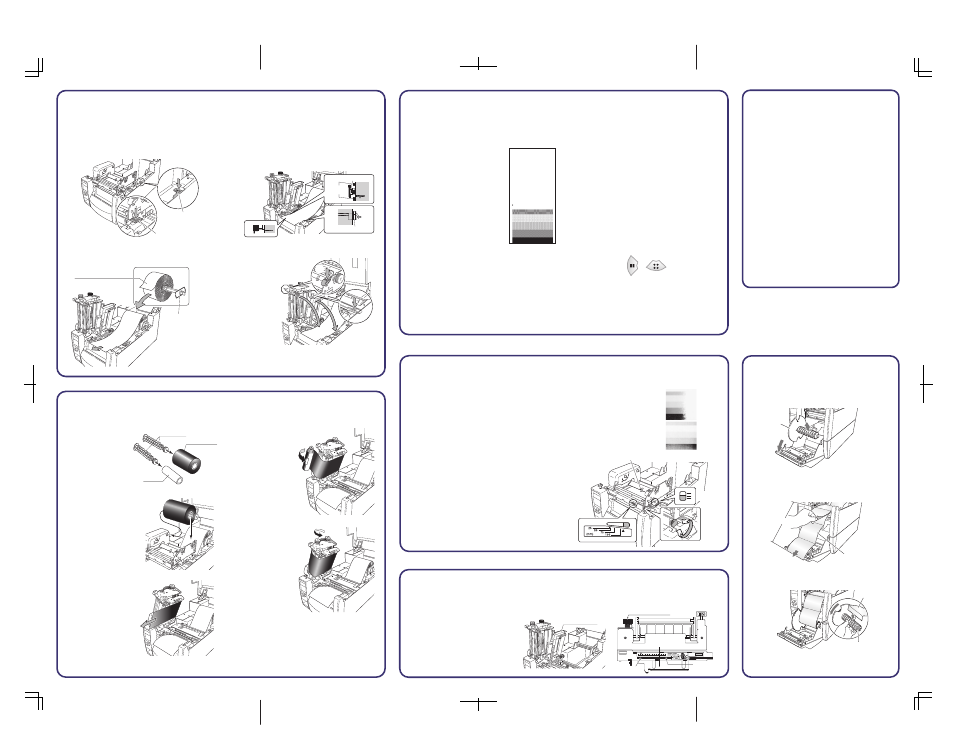

Thermal Transfer Ribbon Installation

5

Printer Configuration

a. Place the unused ribbon

and the empty paper core

(tube) on to the ribbon

holders. Insert the ribbon

holders all the way in to

the ribbon and paper core.

b. Install the unused ribbon and

holder in to the rear ribbon drive

unit.

The splines on the ribbon drive

gear mechanism engage with the

end of the ribbon holder.

c. Open the top cover and then push

the Head open lever to release the

mechanism. You should not open

the media guide bar as this keeps

the media in place.

d. Pull the ribbon past the bottom of

the head unit to the ribbon

winding side. Ensure appro-

ximately 30 cm (1ft) of extra

ribbon is pulled through.

e. Using adhesive tape fix the

ribbon that you have pulled

through the printer on to the

paper tube. Wind (roll) it on the

ribbon

holder

in

an

"anticlockwise" direction.

f. Put the ribbon holder on which

the paper tube has been set in

the ribbon drive unit, then

rotate it in the direction shown

by the arrow to remove slack

and wrinkles from the ribbon.

g. Close the main printer mechanism. Firmly push down on the green part

of the mechanism as (as shown in section 3f) until it clicks closed. Make

sure you hear the "click" from the mechanism otherwise it is not closed.

h. If the ribbon is wrinkled, push the FEED key until the wrinkles disappear.

In the unlikely event the wrinkles do not disappear you may need to

adjust the ribbon tension settings as described in the full user manual

on the CD supplied. This will only usually be needed for specialist or very

narrow ribbons.

Performing a self test print is an easy way to check on the

configuration of the printer. Install the media as explained elsewhere

and then operate the printer as follows.

For label media

Turn on printer power while pushing the FEED

key. When the LCD indicates "Self Print Mode"

and "Label Media", release the FEED key.

For continuous media

Turn on printer power while pushing the FEED

key. When the LCD indicates "Self Print Mode"

and "Label Media", and then changed to "Self

Print Mode" and "Cont. Media", release the

FEED key.

The printer will produce the configuration

report shown.

To restart printing, press the FEED key again.

To exit, switch off the printer.

Changing the Configuration

If the MENU key is pressed while the printer is in the On Line Ready state,

the printer enters menu setup mode. In this mode, the printer's

configuration can be changed using the operation panel. During menu

setting mode, the LCD indicates the current menu settings and the key

function.

Functions of the keys

In the menu setup mode, the four keys become “cursor keys” to navigate

the menu. Refer to the four small arrows in the centre of the keypad rather

than the names of the keys.

The key (Feed key) goes up the menu system or selects a higher value

The key (Menu key) goes down the menu system or selects a lower value

The key (Stop key) selects or saves the item or enters a menu

The key (Pause key) exits the current item (goes back) and eventually

exists the menu system

The menu settings are stored temporarily in the printer's memory. They are

only permanently stored in the printer setup when you exit the menu

system and say “Yes” to the “Save Settings” question.

Quick selection between DT and TT

The print method (thermal transfer method/direct thermal method) can be

set using operation panel in addition to menu setting mode.

Caution:

Ensure the printer is not printing or in pause mode. You cannot change

between print methods unless the printer is in 'On Line Ready' mode.

Setting method

Keep the MENU key held down. Each time the PAUSE key is pushed, the

printer switches between thermal transfer mode and direct thermal mode.

If thermal transfer is selected, the buzzer sounds once and the LCD

briefly displays “Print Method, TT” before returning on-line.

If direct thermal is selected, the buzzer sounds twice and the LCD briefly

displays “Print Method, DT” before returning on-line.

Note:

If you just press the MENU button on its own and do not press PAUSE, you

will enter the full Menu Setup Mode.

Using the Configuration / Self Test Print as described above, you can make adjustments to the

printer settings such as media width and media thickness (printhead pressure).

Width Adjustments

The sample, top right, shows an incorrectly set "media width adjustment" . The printed image disappears on the right

side of the image.

To change the media width setting, rotate the small adjustment knob on the right side of the printhead, as shown in the

diagram. The indicator window (which may be obscured by the ribbon) shows an approximation of the setting. The

small arrow indicates "full" width of just over 4 inches, 100mm.

Thickness Adjustments

The second sample, right, shows an incorrectly set "media thickness adjustment".

The printed image appears light, grey or speckled. This can also be caused by

incorrect heat setting.

To adjust the media thickness, use a cross-point screwdriver inserted in to the

"thickness adjustment" hole on the top of the mechanism (which may be

obscured by the ribbon).

Turning the screw clockwise cause the indicator to drop. This is for thicker media

such as card and tags. Turning anti-clockwise the adjustment indicator raises

which is for thinner media like thermal paper rolls.

The centre line is the factory setting and is suitable for normal labels.

Yellow mark

Media guide arm

(viewed from above)

Sensor adjustment knob

Adjustment

window

Machine Information

Model Number

:7010-S700

Boot Version

: ****

ROM Version

: ********

ROM Date(DD//MM//YY)

: 07/10/03

ROMCheck Sum

: ****

Head Check

: OK

Print Counter

: 0002.234km

Service Counter

: 0002.234km

Sensor Monitor

: 1.50V

Option Interface

: None

Current Menu Setting

[PageSetup Menu]

Print Speed

: 10 IPS

Print Darkness

: 10

Darkness Adjust

: 00

Print Method

: Thermal Transfer

Continuous Media Length

: 4.00 inch

Vertical Position

: 0.00 inch

Horizontal Position

: 0.00 inch

Sensor Select

: Rear Adj Sensor

Media Sensor

: See Through

Small Media Adjustment

: Off

Small Media Length

: 1.00 inch

Fixed media guide

Media

Media

Moveable media guide

Projected

metal guides

a. Media installation is very straightforward and easy. Firstly, open the

printer cover to view the printer's mechanism and media holder.

b. Push down the Head open lever to release the printhead. Then push

down the Sensor arm open lever to lift the Media guide up.

c. Insert the “Media holder assembly” into the core of the roll of media.

Place the roll of media on the 'Media holder' and push the roll to the left

side wall to secure the roll.

d. (1) Push media against the fixed media guide on the left side.

(2) The moveable media guide should be adjusted so it touches and

guides the media. It must not bend or restrict the media from

passing through the printer.

(3) The media should run through the printer straight so the left edge

is aligned with the projected metal guides and the fixed media

guide.

e. Hold the media so as to ensure it cannot move or skew, push down the

Media Guide to close it.

f. Close

the

main

printer

mechanism. Firmly push down on

the green part of the mechanism

as shown below until

it clicks closed. Make

sure you hear the

“click”

from

the

mechanism otherwise

it is not closed.

g. Close the printer

cover and turn ON the

power switch of the

printer. The

LCD

screen on the control panel will show 'On Line Ready.' Then press the FEED

key and media will advance to the next label position and stop.

Media installation

9

Peel & Rewind Mode

(7010R only)

a. Open the rewinder cover and remove the rewinder spool.

b. Pull out approximately 40cm length of the media from the head

unit.

c. Peel off all the labels from the 40cm of media so that the liner is in

contact with the peeler roller when closing the front door.

d. Insert the end of the liner through the slot in the rewinder spool

and wind it two or three times around the spool to ensure it grips.

Then set the rewinder spool in the printer.

e. Close the rewinder cover door by pushing the top of the door

quite firmly until it clicks closed.

PAUSE

MENU

+

Hold

Press/Release

Media (liner)

Approximately 40cm