Media installation, Unusually shaped media adjustment, Windows – Dascom 7206 Quick Start Guide User Manual

Page 2: Drivers, Self tests and printer configuration, Thermal transfer ribbon installation, Printer driver installation, 7206 only), Self test print, Media adjustments

3

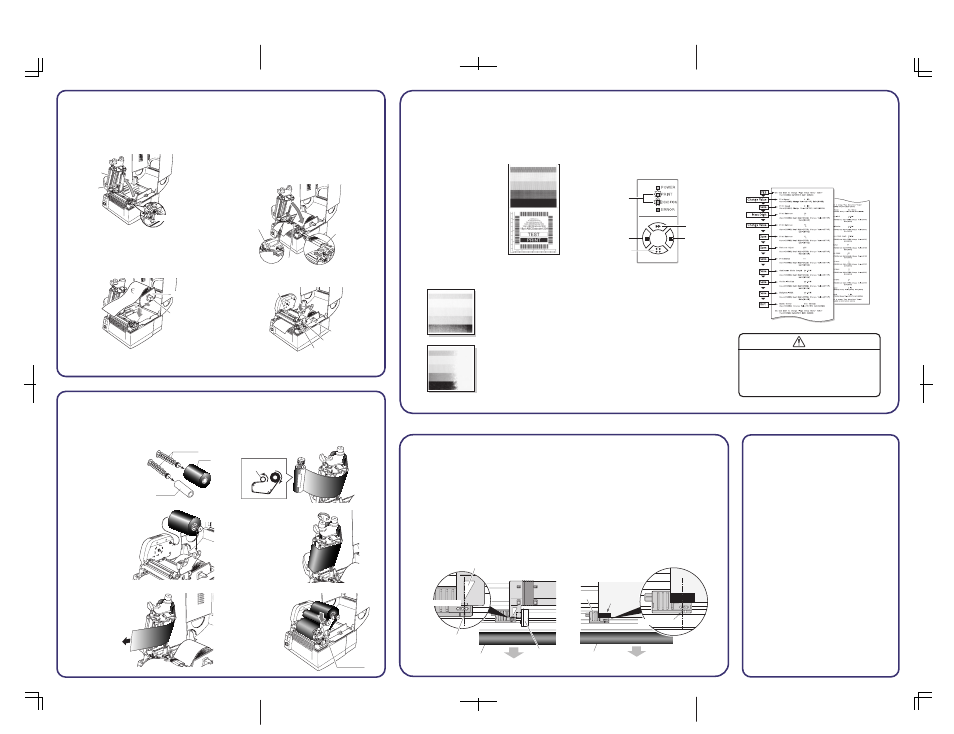

Media Installation

6

Unusually Shaped Media Adjustment

Printer Driver Installation

If the drivers are not included with the printer, you can download the

latest version free-of-charge from our web site, details of which are on

the back of this Quick Start Guide.

Under the latest versions of Windows

®

, the computer will often

automatically detect the presence of the printer. Therefore it is

advisable to download the drivers from our web site before installing

the printer so the files are ready for installation:

www.dascom.com

During installation of the printer driver, the computer may ask you to

select the printer required.

You will need to click on the "Have Disk..." box then tell the computer

the location of the driver files on your CD ROM.

Your supplier will assist you with the correct drivers and software

which are compatible with your particular computer system if you are

not using Windows

®

.

Windows® is a trademark of Microsoft® Corporation.

7

Windows

®

Drivers

4

Thermal Transfer Ribbon Installation

(7206 only)

5

Self Tests and Printer Configuration

a. Push the large blue head open lever to release the head unit and then

raise it to the position shown below. On the 7206, you will also need to

raise the sensor arm by simply lifting it, the 7106 does this automatically.

b. Firstly, slide the two black plastic parts of the media holder assembly

together. Ensure correct alignment of the guide with the bar as it can

only be installed in one direction.

c. Slide the roll of media over the media bar. The media guide must be on

the right side of the roll of media (as viewed from the front of the

printer) with the ribbed surface of the media guide touching the media

roll as shown in the illustration.

d. Set the media roll and media holder in to the printer as shown above. It

is advisable to pull a length of media forwards and through the

mechanism ready for later positioning.

e. Move the media roll so it is touching the left side of the housing. Then

slide the black media guide so it is touching the media on the right

side. Do not try to hold the media too tightly with these guides as it will

cause the printer to jam during printing.

f. You may need to adjust the media sensors as described in section 6.

This will depend on the media types you are using.

g. Align the media with the left fixed media guide, align the right movable

media guide with the media width, and lower the sensor arm.

h. Lower and lock the head unit. Align it with the width of the media that

has been set, then set the media width and media thickness adjustment

dials. See section 5 for more info.

i. With the power switched on, push the FEED key to feed the media. It will

halt at the next print start position.

Media installation

Sensor arm

Large blue-head open lever

Head unit

Media holder bar

Media holder guide

Fixed media guide

Sensor arm

Movable media

guide

Head close knob

Media width adjustment

Media thickness adjustment

Head unit

To detect gaps between labels and for media with notches or holes, use

the transparent or see-through sensor:

a. First, move the lower sensor to the center of the media installed or

in line with the hole or notch in the media.

b. Then align the upper sensor marker with the lower sensor marker as

shown in the diagram below.

c. For easy and quick alignment (and to reset to factory positions)

slide both the upper and lower sensors to the right-most position of

travel. They will now be perfectly aligned over the centre of the

mechanism.

To detect media with black ‘registration’ marks on the back of the media,

use the reflective sensor:

a. In reflective sensor mode, only the lower sensor is used.

b. Adjust the position of the lower reflective sensor so that the marker

is at the center of the black mark on the media as shown below.

c. The upper sensor arm is still closed over the media to help guide it

through the printer, even though the upper sensor arm is no longer

used.

For non-standard media sizes and shapes, you may need to adjust the media sensors from their usual positions

Movable

media guide

Upper sensor

Bottom sensor

Transparent

sensor marker

Upper sensor marker

Front

Aligned with the marker

Platen

Front

Black mark

Media

Bottom sensor

Reflective sensor marker

Black mark

Platen

1

2

Ribbon holders

Paper core

Ribbon

Winding side

ribbon holder

Winding side

ribbon holder

Head close knob

f. Put the ribbon holder which holds

the cardboard tube in the ribbon

drive unit, then rotate it in the

direction shown by the arrow

to remove slack and wrinkles from

the ribbon.

g. Push the head close knob to lower

and lock the head unit. Be sure to

always push the head close knob

to lock the head unit

h. If the ribbon is wrinkled, push the

FEED key until the wrinkles

disappear. If the wrinkles

do not disappear or if it slips,

perform ribbon balance

adjustment and ribbon

tension adjustment as

described in Chapter 3 of

the full user’s manual

on the CD supplied.

b. Place the new, unused ribbon and the

paper core (tube) on to a ribbon

holder each.

Insert the ribbon holders all the way

in to the ribbon and paper core.

c. Install the unused ribbon and holder

in to the rear ribbon drive unit.

The splines on the ribbon drive gear

mechanism engage with the end of

the ribbon holder.

d. Push the head open lever to release

the head unit. Pull out the ribbon

from the bottom of the head unit to

the ribbon winding side.

a. Check the kind of ribbon used and set the ribbon winding direction using

menu setup mode or operation panel. This is the method for installing an

outside wound ribbon (also known as “ink out”).

e. Using the adhesive leader of the ribbon or some adhesive tape, fix the

end of the ribbon to the empty cardboard ribbon holder and wind on

some ribbon.

STOP key (CHANGE/NO)

PAUSE key (YES)

MODE/REPEAT key (EXIT)

Light up

FEED key (CURSOR)

Self Test Print

Performing a self test print is an easy way to check on the state of printer

settings and print quality. Install the media as explained in sections 3 & 4

and then operate the printer as follows.

For label media

Turn on printer power while pushing

the FEED key. When the PRINT LED has

begun to flash slowly , release the FEED

key.

For continuous media

Turn on printer power while pushing

the FEED key. When the PRINT LED has

stopped flashing slowly and has begun

to flash rapidly , release the FEED key.

The printer will produce the self test

shown, then it will stop. To repeat, press

the FEED key again. To exit, switch of

the printer.

Media Adjustments

Using the Self Test Print shown above, you

can make adjustments to the printer settings

such as media width and media thickness

(printhead pressure). The location of these

two adjustments is explained in section 3.h

and also shown on the labels on the printer's

mechanism.

The first sample, left, shows an incorrectly

set “media thickness adjustment”. For

standard label media, it is recommended you

set the blue dial to the “0” position.

The second sample, left, shows an incorrectly

set “media width adjustment”. For 4-inch or

100mm wide media, the adjuster should be

set to the “9” position on the blue dial.

The settings shown above are for general label

media and may not apply to specialist media.

Shown below is a sample menu output from the menu system.

This particular example is changing the print speed and print darkness

then continues through the remainder of the “Print Setup” menu.

The actual output from the printer is “vertically reversed” due to the way

the printer outputs the menu options. Please look at the example below to

see how the output changes.

Functions of the keys

After each menu item is printed, the printer will also print the function of

each of the buttons at that time. They vary slightly depending on the menu

selected but generally fit the following guidelines:

PAUSE key (YES):

:

It is pushed to either select the current menu

option or to save the new setting after which

it advances to the next menu.

STOP key (CHANGE/NO):

:

Whilst changing a menu value (such as head

temperature), pressing this key displays the

next menu value available but does not save

the setting.

In the “main menu”, pressing this key moves

to the next menu available.

FEED key (CURSOR):

:

With some menu options such as head

temperature, there is more than one “digit”

than can be changed. This key moves the

cursor to the next digit.

MODE/REPEAT key (EXIT):

:

Exits the current menu or the menu system.

Printer Configuration Menu

If the printer power is turn on while the MODE/REPEAT key is pressed, the

printer enters menu setup mode. In this mode, the printer’s configuration

can be changed using the menu system. During menu setting mode,

the CONDITION LED is on. Media must be installed in the printer to use

the Menu System.

When you are changing a menu value, pressing the "PAUSE" key (YES)

causes the printer to save the currently selected parameter.

The CONDITION LED flashes briefly. Do not turn off the power to

the printer at this time as this may cause a malfunction.

If the power is accidentally turned off, first reset the printer to factory

defaults.

Caution