System installation instructions, continued, Figure 3 - tethered pump switch, Figure 4 - j-box wiring diagram – Clarus Environmental Centrifugal STEP Systems User Manual

Page 3

3

© Copyright 2014. All rights reserved.

7. Bring piping from the lateral field to the outside of the riser on the

septic tank. Note: If installing a system using a control panel follow

the instructions included with the panel and skip steps 11-12 and 15.

8. Disconnect Clarus Environmental flexible pipe assembly at union

on ball valve. Install pipe seal through the riser wall (2” hole saw

required) to prevent ground water intrusion. Install flexible pipe

through pipe seal with union ball valve on inside of riser as shown

in Figure 1A. Solvent weld flexible pipe to lateral field piping using

PVC pipe cement.

9. Connect other part of 1 ¼” discharge pipe assembly to pump outlet

with pump setup outside the pump tank.

10. Tie off power cord by strapping to the discharge pipe. Make certain

the cord cannot become entangled or obstruct the movement

of the floats.

11. Install wire from power source and the alarm. See Fig. 1A or 1B. If

a junction box is being used, Fig. 1A, install inside the septic tank

riser. If a Qwik Box System is being used, Fig. 1B, install outside of

septic tank riser as shown in Fig. 1B or inside of septic tank riser.

Note: Some codes require the junction box to be outside the riser.

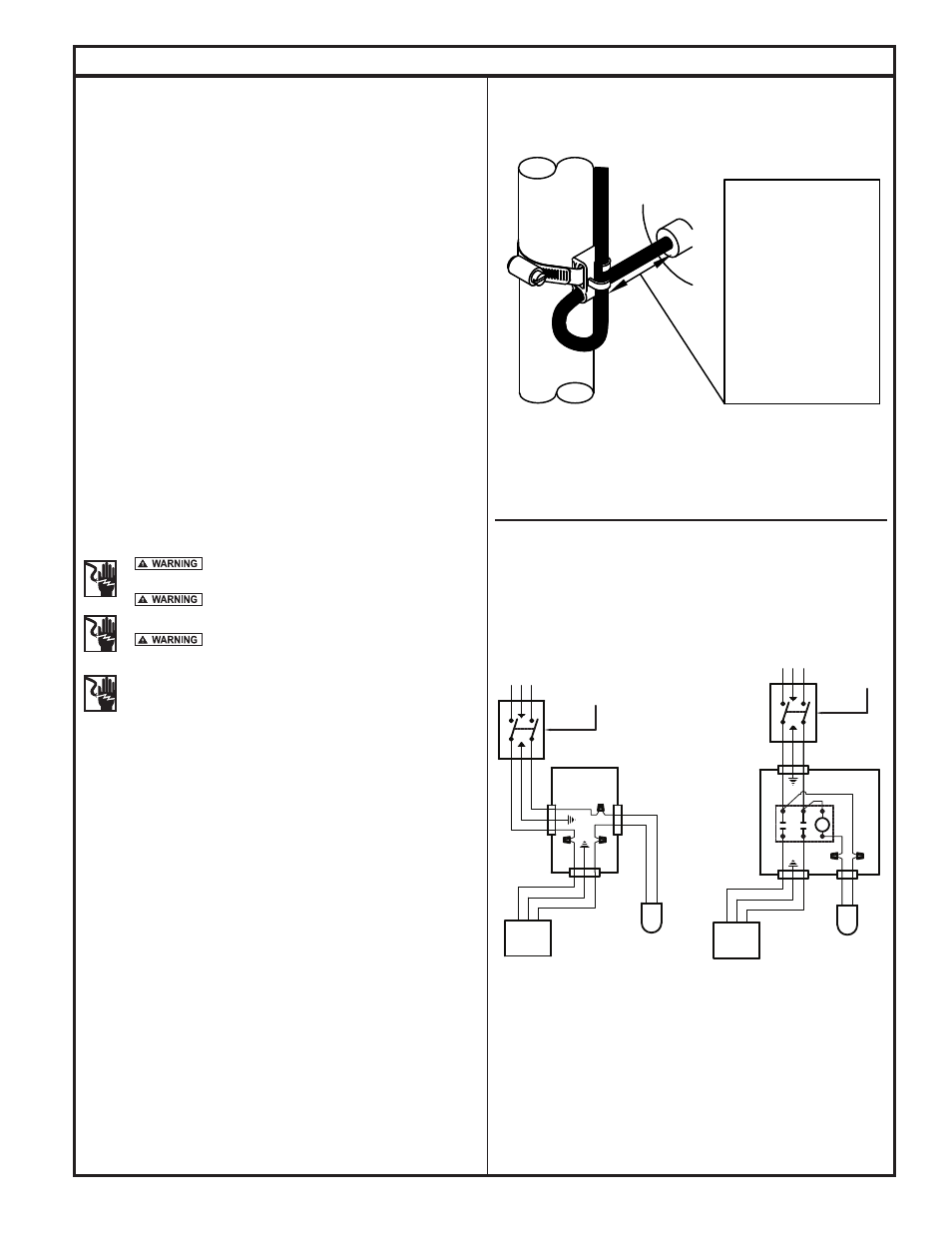

12. Install pump switch on discharge pipe using the included band clamp.

Place the band clamp as low on the discharge pipe as possible.

Tether the pump switch so that 3.5" of cord exists between the float

and the clamp. This will yield a 7" drawdown cycle. Additional

tethers can be used if state, local and regional codes permit.

System Installation Instructions, continued

Figure 3 - Tethered Pump Switch

SK1301

Note: Some codes require the junction box to be outside the riser.

Figure 4 - J-Box Wiring Diagram

“Risk of electrical shock” Do not remove power

supply cord and strain relief or connect conduit directly to the pump.

Installation and checking of electrical circuits and

hardware should be performed by a qualified licensed electrician.

For your protection make certain the pump

ground wire is properly connected to the ground wire with the

incoming power line. Test for ground at the junction box using

an Underwriters Laboratory listed circuit analyzer which will indicate

if the power, neutral and ground wires are correctly connected. If in

doubt, call a qualified licensed electrician.

13. Measure length of hanger pipes by measuring inside the riser. Cut and

install hanger pipes in filter tank and lower the assembly into the septic

tank opening. Tie off power cords by strapping to discharge pipe. Make

certain cords cannot become entangled or obstruct the movement of the

floats. See Fig. 1. Lower pump with discharge pipe and float assemblies

into filter tank.

14. Adjust piping using threaded elbows and flexible piping provided to achieve

proper fit. Connect union on ball valve.

15. Install the alarm inside the house or in a weather protected location per

installation instructions with alarm kit, making sure the alarm is plugged into

a different circuit than the pump circuit. Complete the wiring connections. If

a junction box is being used, Fig. 1A, wire per diagram in Fig. 4. If a Qwik

Box outside connection is being used, wire according to the installation

instruction provided with the Qwik Box unit. All wiring, from the power

source to the pump, must conform to the National Electrical Code. Be

sure to leave a sufficient amount of cord so the filter can be serviced

without disconnecting the cordage from the junction box or Qwik box.

See Maintenance section on back page.

16. Fill the septic tank with water and check the alarm level before placing

the system into service. See operation and start-up areas of this manual.

SWITCH

SK306

3.5 INCH

TETHER LENGTH

FOR DOUBLE

FLOAT

3.5 INCH

MINIMUM

TETHER LENGTH

FOR PUMP

SWITCH

WHITE

BLACK

WHITE

GREEN

BLACK

BLACK

GREEN

WHITE

BLACK

WHITE

R

L1

L2

L2

L1

PUMP

DISCONNECT

SWITCH

WATERTIGHT

JUNCTION BOX

VARIABLE

LEVEL

PUMP SWITCH

PUMP

CONTROL SWITCH

VARIABLE

LEVEL

DISCONNECT

SWITCH