Bush Hog TD-1100 User Manual

Page 13

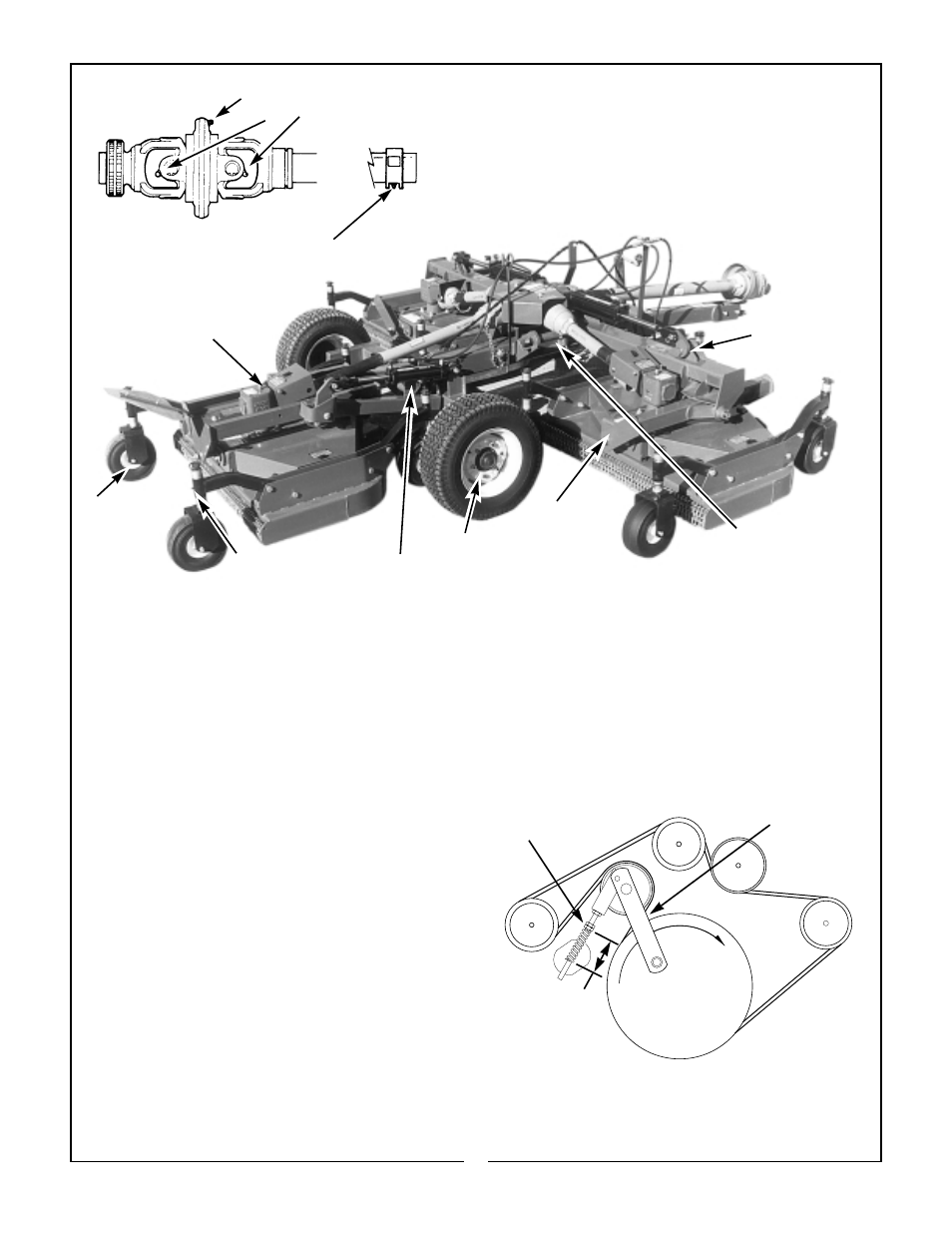

Figure 4-1 B (5) 30 Shots Before Each Use

(1) 3 Shots Before Each Use

(5) 10 Shots Before Each Use -

(Access through holes in shields of

telescoping driveline)

(9) 40 Hrs

(7) 40 Hrs

(3) Before

Each Use

(4) Before Each Use (10) 40 Hrs

(11) End Of Season

(8) 40 Hrs

Figure 4-1 C

4-3 SPINDLE BELT ADJUSTMENT

Belt tensions should be checked every 40 hours to

get maximum life from drive belts and best perfor-

mance from the cutter. Belt tension is adjusted by

increasing or decreasing the length of the spring on

the moveable idlers. For proper belt tension on

the mower, the spring lengths should be set at 2-

7/8”. (Figure 4-2) To adjust the spring length, loosen or

tighten the 1/2” hex nuts on the spring adjustment rod

until the correct spring length is reached.

4-4 SPINDLE BELT REPLACEMENT

Use only genuine Bush Hog replacement parts.

A. Flip up black latches and remove right and left

side shields. To remove the outside shields on the

wing cutter decks, the wings must be in the folded

position.

B. Relieve spring tension by loosening the two 1/2”

hex nuts on each spring adjustment rod. (Figure 4-2)

C. Remove old belt.

D. Install new belt as shown below. (Also refer to

the decal on underside of belt shield)

1. Disconnect the adjustment rod from the idler

assembly. (Figure 4-2)

2. Place belt into the groove on the driving

sheave.

3. Work the belt over the other sheaves.

4. Connect the adjustment rod and the idler

assembly.

5. Tighten the compression springs on the

drive to 2-7/8” long. Tighten the jam nut on the

adjustment rod.

6. Replace all shields before operating machine.

Figure 4-2 Spindle Belt Diagram

Adjustment Rod

& Spring

Idler Assembly

Driving Sheave

At Gearbox

2-7/8”

11

(10) 40 Hrs