Troubleshooting suggestions, General maintenance instructions – Carter-Hoffmann CAA144 User Manual

Page 10

10

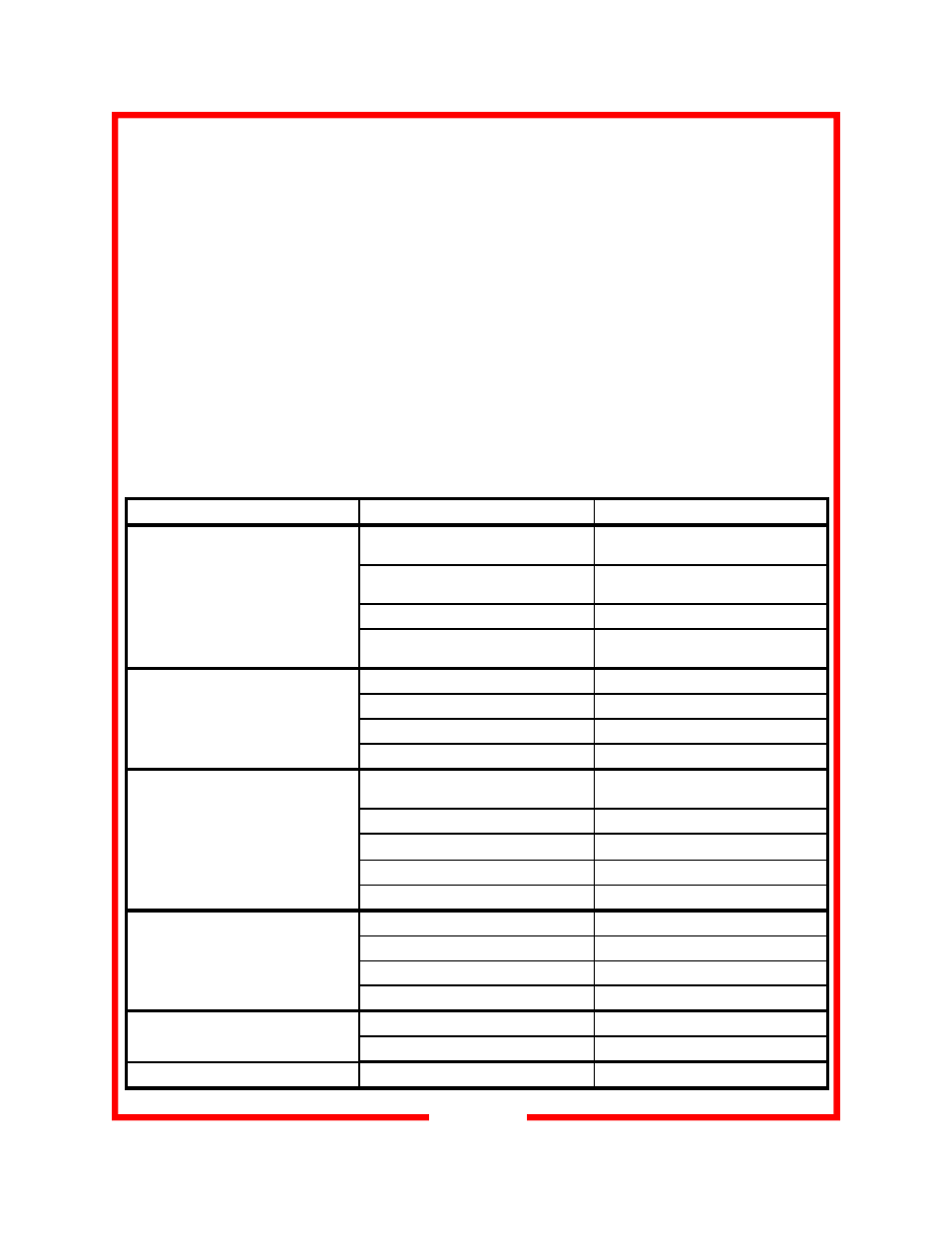

TROUBLESHOOTING SUGGESTIONS

PROBLEM

PROBABLE CAUSE

POSSIBLE REMEDY

No power to unit,

No light on display

Motor not running

Not plugged in or circuit breaker off or

tripped

Plug into receptacle. Reset circuit

breaker, check facility circuit breaker

Main switch damaged

Check main power switch, replace if

damaged

Damaged power cord

Replace cord

Hi-limit safety tripped

Allow unit to cool, hi-limit will reset auto-

matically, or replace

Unit does not hold temperature

Damaged door gasket

Replace gasket

Damaged door latch

Replace defective latch

Temp probe damaged

Replace probe

Door gap, out of alignment

Adjust door hinging and strike

Unit does not heat / cool

Cabinet temp above set point (heat)

Cabinet temp below set point (refrig.)

Adjust thermostat set point

Check thermometer calibration

Damaged wiring

Repair wiring

Damaged relay

Replace relay

Damaged controller

Replace controller

Damaged heating element

Perform ohm reading, Replace element

Unit overheats

Set point too high

Change set point

Thermostat damaged

Replace thermostat

Defective hi-limit control

Replace hi-limit

Blower fan jammed

Find source of fan binding

Blower motor not running

Damaged fan motor

Replace motor

Blower fan jammed

Find source of fan binding

Relay is “chattering”

Check proper wiring to switch

Repair wiring or replace switch

GENERAL MAINTENANCE INSTRUCTIONS

CASTERS

Some casters are equipped with Zerk grease fittings so that they may be easily lubricated with a grease gun.

Recommended lubrication is at least once every six months. Lubrication will be required more frequently if carts

are cleaned with a hot water or steam cleaning system. Casters with special bearings are recommended for fre-

quent cart wash or steam cleaning situations.

LATCHES

Check frequently to insure that all door latches are secure. Latches may become “sticky” due to residue build-up

from daily use and cleaning. Lubricate latches regularly with WD-40, silicone spray, graphite or other commercial

lubricants for stainless steel products. Do not use oil.

PERIMETER BUMPERS

Vinyl which has been dislodged from the channel due to severe bumping or scraping can be pried back into

place with a common screwdriver.

CONTROLLER MAINTENANCE

Routine maintenance is not required. A periodic check of the system calibration is recommended. The controller

is not field serviceable. Call for service if repair is needed.