Shooting tips & techniques – BLACKHAWK! SPECOPS NRS SHOTGUN STOCK User Manual

Page 3

www.BLACKHAWK.com

BLACKHAWK!

®

NORFOLK, VA U.S.A. 1.800.694.5263

www.BLACKHAWK.com

BLACKHAWK!

®

NORFOLK, VA U.S.A. 1.800.694.5263

Shooting Tips & Techniques

Page 5

Page 2

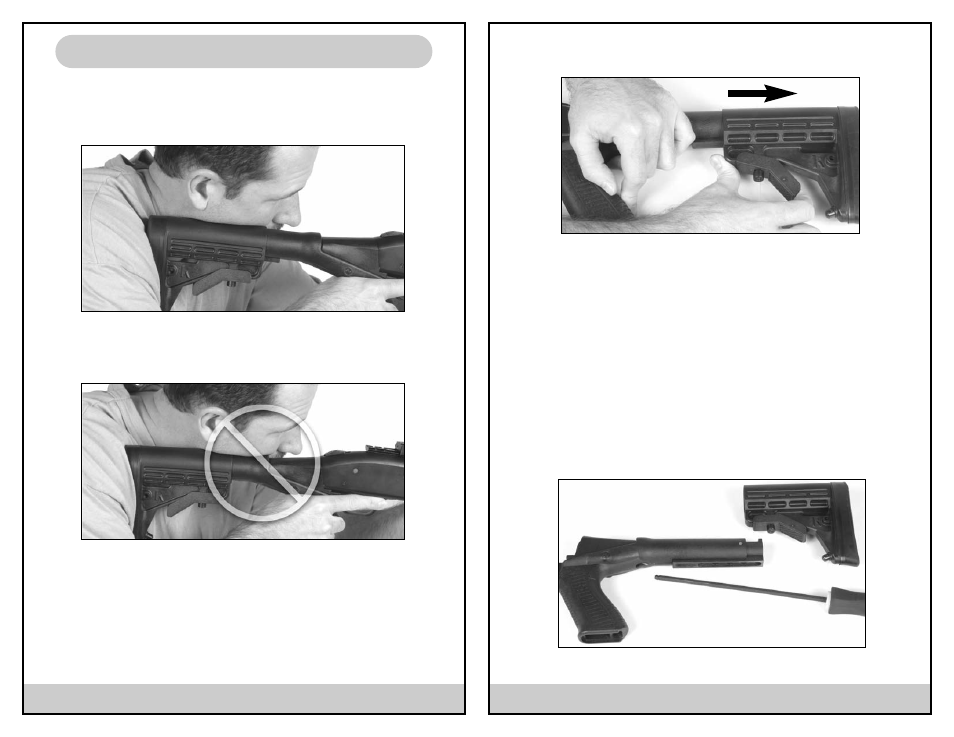

IMPORTANT NOTICE: To avoid “cheek-slap” maintain a minimum space between cheek

and flare on front of stock. (Fig. 6 & 7) If “cheek-slap” persists, position face further back

or extend stock one position.

2. Prepare SpecOps NRS for installation by removing rear butt stock from SpecOps NRS.

To remove pull down on lever assembly and slide off buttstock. (Fig. 2)

Note: For Mossberg SpecOps NRS only, remove rubber o-ring from stock bolt. Remove o-ring by

inserting ball end allen wrench into hole located on the bottom of the SpecOps NRS. Turn wrench

counter clockwise while applying pressure to the bolt with finger. Turn wrench until rubber o-ring

is removed.

3. To begin installation attach the SpecOps NRS to the shotgun by aligning pistol grip with the rear

of the shotgun receiver. Insert ball end allen wrench into the hole located on the bottom of the

SpecOps NRS (Fig. 3) and firmly tighten the pre-installed Hex head bolt and washers. Make sure

that the stock is properly aligned and square with the receiver. (Be careful not to strip or cross

thread mounting bolt or receiver nut).

Note: For Mossberg SpecOps NRS, there should not be a gap between stock and shotgun after

installation. Continue to tighten bolt until gap is closed.

RIGHT: Maintain at least 1" space between cheek and flare in stock.

Maintain a comfortable cheek weld, avoid mashing or pushing face

down into stock.

WRONG: No space between cheek and flare will result in shooter

discomfort or cheek-slap.

Fig. 2

Fig. 3

Fig. 6

Fig. 7

Note: If the stock is loose or if there is a significant gap between the stock and receiver after

completely tightening the bolt, then two issues may exist. Issue 1; the bolt has been cross

threaded into the receiver nut. Issue 2; there is debris (powder residue or old thread locking

compound) in the receiver nut that is not allowing the stock bolt to fully engage with all the

receiver nut threads. To clean receiver nut threads, take a small diameter barrel brush (Approx

1/4” dia.) and insert repeatedly into receiver nut until excess material has been removed.

Re-install stock.