BASELINE Motorcycle Ready Addendum User Manual

Page 4

4 •

BaseLine

5a.

Prior to placing the wheel on the table top to

clamp, observe the style and strength of the wheel

and adjust the clamp pressure as necessary using the

pressure regulator and gauge. Thin spun aluminum rims

sometimes used on ATV and motorcycle are some-

times delicate and a reduced air pressure should be

considered verses cast aluminum and steel wheels that

can support more clamping force.

5b.

Next, observe the rim size from the tire, i.e. 15,

16, 17, etc. Using the clamp pedal, place the clamp valve

in the JOG IN position for prelocating the clamps to

the rim diameter. Accomplish this by moving the pedal

from the UP position to the 1/2-DOWN location. Then

JOG the pedal DOWN allowing the clamps to move

inward until the pointer on the clamps align with the rim

diameter on the table top decal. It may be necessary to

relocate the clamps on the clamp carriers. Each clamp

should be in the same position before prelocating the

clamps.

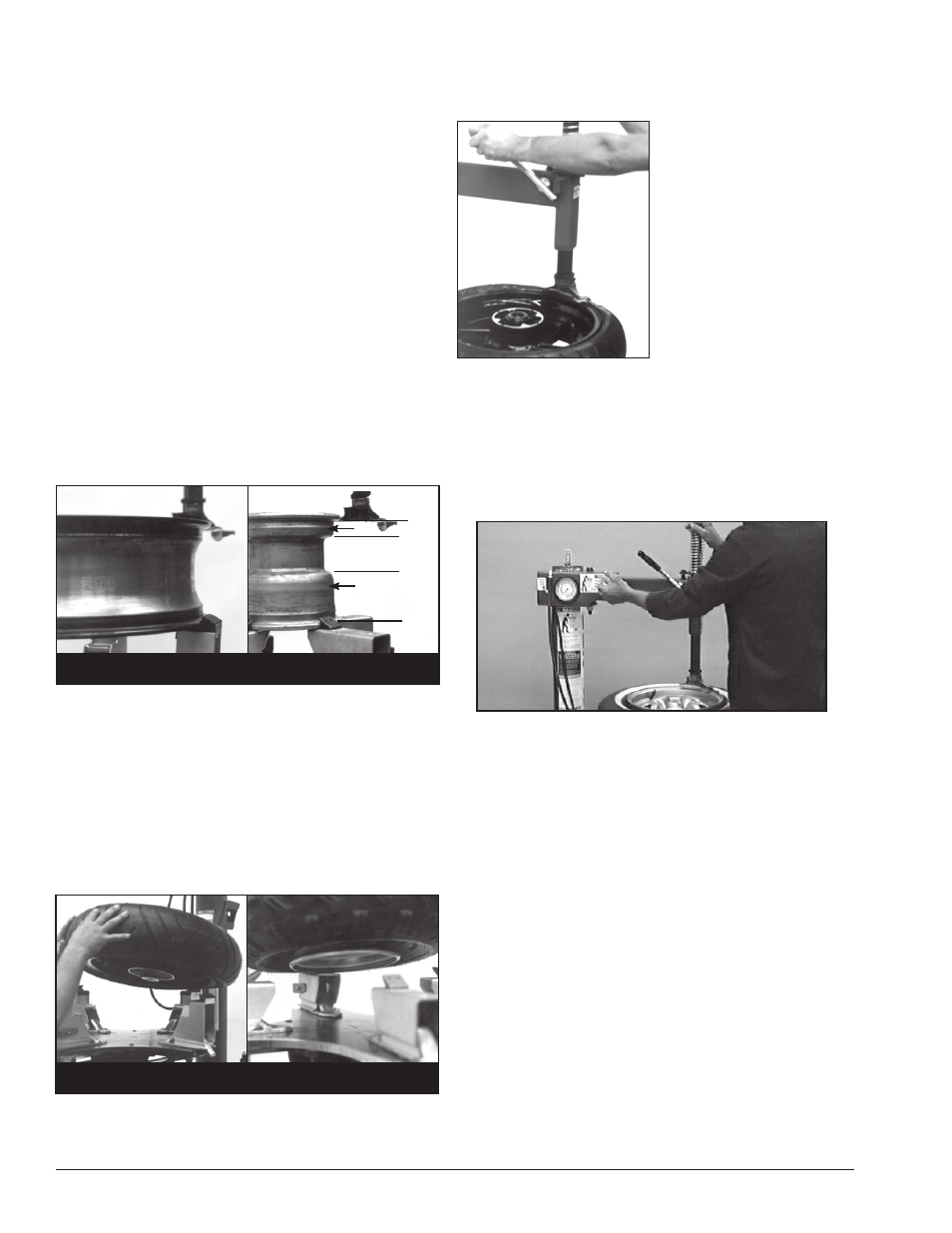

5c.

Determine the mounting side of the wheel. The

mounting side is the narrow side of the drop center.

(Tire removed in Figure 4 for clarity.)

Figure 4 - Determining Mounting Side of Wheel

6.

Place tire/wheel assembly on table top with mount-

ing side up (Figure 5). Use the clamp control pedal to

move the clamps inwards (push pedal down) or out-

wards (toggle pedal up). Clamp motorcycle and ATV

wheels from the outside (clamps push inwards against

the outside rim edge). Place rim flange into rear clamp

and slowly move the other clamps inward until they

contact the rim. Observe closely to prevent tire/wheel

damage.

Figure 5 - Place Tire/Wheel Assembly on Table Top

7.

Move the swing arm into position. Pull the lock-

ing handle forward to release the slide. Push down

on the top of the vertical slide to move the demount

tool into contact with the

rim edge. Push the lock-

ing handle back to lock the

slide into place. As the

slide is locked, the mount/

demount tool will move

upward approximately 1/8

inch from the rim edge.

Note: On plastic mount/

demount tool, the upward

movement should be

limited to 1/16-inch maxi-

mum.

Figure 6 - Position Mount/Demount Tool

8.

The mount/demount tool roller should be in contact

with the rim edge. Turn the swing arm adjusting knob

to move the tool away from the rim 1/8 to 1/4 inch.

On expensive and polished rims, it is recommended a

plastic bootie (p/n 8183373) be used over the mount/

demount tool roller.

Figure 7 - Adjust Swing Arm to Position Tool Roller

9.

Check tool positioning. Mount/demount tool should

be positioned with 1/8 to 3/16” clearance between the

top of the rim edge and the bottom of the tool (with

plastic mount/demount tool it is recommended the ver-

tical clearance be limited to a maximum of 1/16-inch),

and 1/8 to 1/4 inch clearance between the rim edge and

the tool. This clearance will be maintained as long as the

locking handle and adjustment knob are not changed.

The operator may swing the arm out of the way and

back into place again without needing to reposition the

tool (when changing a set of the same wheels).

Motorcycle

Motorcycle

ATV

ATV

Motorcycle

Motorcycle

ATV

ATV

Narrow Side

Drop Center

Long Side