Barranca Diamond HP14 Slab Saw User Manual

Page 14

14

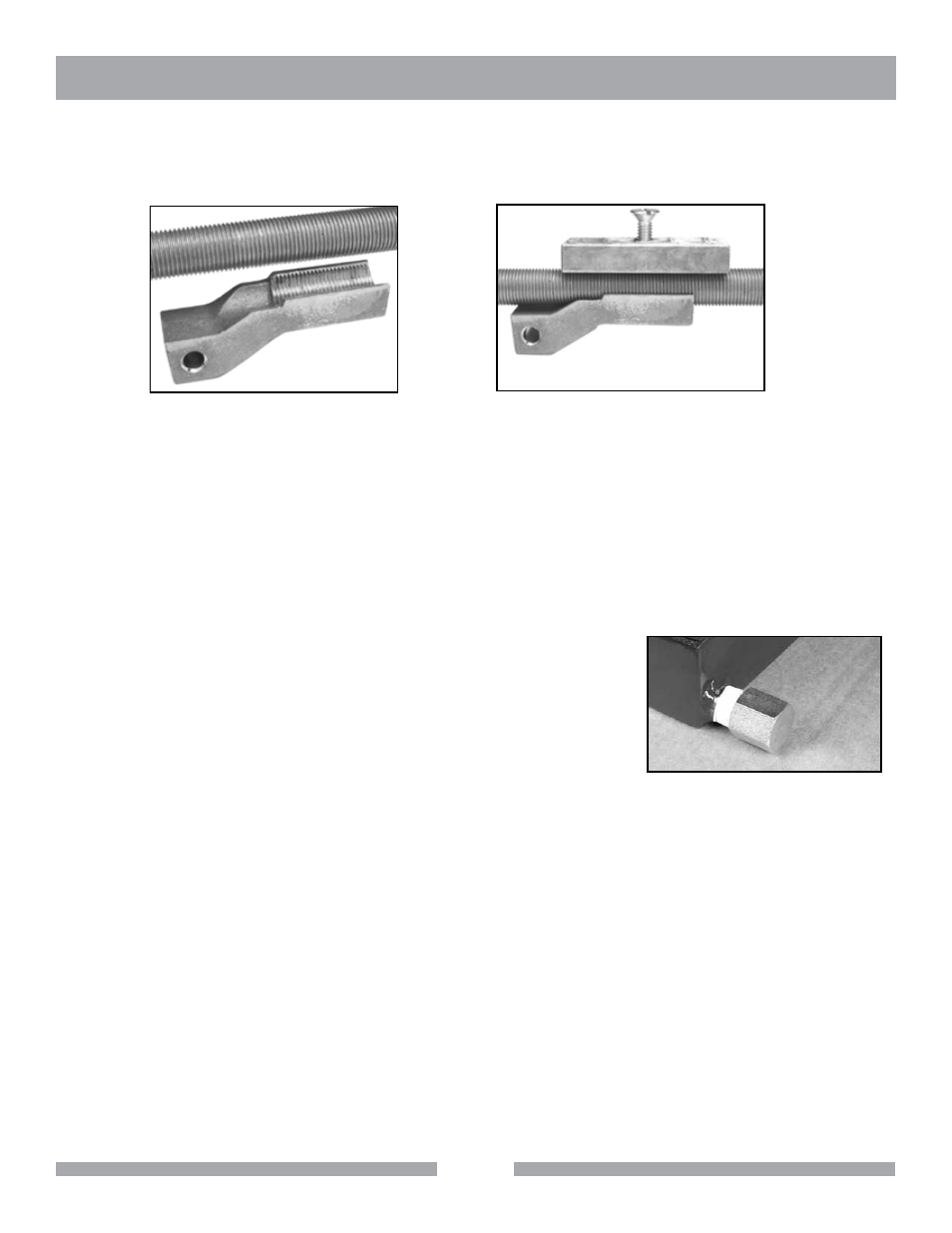

This adjustment will help the clutch block shoe to snugly engage the stainless steel feed screw by applying

pressure to the brass pressure block below the carriage casting. Should you have trouble with this adjustment

call Barranca Diamond at (800) 630-7682 for factory assistance in clutch adjustment.

Brass pressure block, feed

screw & clutch block shoe

Feed screw & clutch block shoe

Periodically, it will be necessary to replace the silicon bronze clutch block shoe once the 3/8"-24 threads are

flattened or stripped. You may purchase the clutch block and pressure block direct from the factory. See parts

lists on pages 20 and 21 to order correct parts by part number and description of part(s).

Repeat this process if necessary to readjust the engage/disengagement clutch to improve positive feed move-

ment of the carriage-vise system. If the gap between the shoe and pressure block is too tight the clutch will not

engage correctly. It will need to be adjusted so that the pressure block position is repositioned by turning the

set screws counterclockwise to raise the block away from the feed rod.

LUBRICATING OIL REPLACEMENT

The HP14 Slab Saw requires periodic routine maintenance to remove and

discard properly the build up of rock mud "sludge" and dirty lubricating

fluid (oil) from the oil reservoir pan. It will be apparent to the user from the

condition of the oil that the lubricating fluid is dirty and needs to be changed

and solid sludge removed from the oil pan if a thick and viscous oil residue

builds up on the saw vise/carriage, and inner tank walls. The liquid oil can

be removed rapidly using the drain pipe attached to the bottom drain hole at

the base of the oil reservoir (Photo 13).

A five gallon bucket or collection container can be placed under the outlet cap of the pipe and the cap removed

with a pipe wrench or channel locks to let the free oil flow into the bucket for proper disposal. The sludge resi-

due will likely not flow into the drain pipe upon removing the cap from the drain pipe. Therefore, a portion of the

sludge (solids) can be removed with a scoop, large spoon or spatula when the slab saw oil lubricant is drained.

Once the majority of the liquid oil has been drained, remove the blade from its shaft and then remove the bot-

tom oil pan from the saw’s main tank top by unbolting the fastening screws. Lift off the upper tank and hood

with help from another person and extract the sludge pan and set it aside. With a spatula or spoon, scoop out

the sludge/mud to clean out the build up of sludge. Once the sludge is removed, wipe clean the inside of the

tank with disposable rags or towels, reposition the gasket between the bottom pan and main tank body and

reassemble the saw. Refill the cutting lubricant to the proper level (1/4 to 3/8" of blade kerf immersed in cutting

oil).

Be sure to check the fluid level of the cutting lubricant inside of the oil reservoir after every 2 to 3 hours of use

as the fluid will be absorbed onto the rock slabs, combined with rock mud (sludge), and lost due to heat, mist-

ing and evaporation as well.

Photo 13

HP14

MAINTENANCE