Maintenance, 1 maintenance devices, Maintenance devices – Autoquip TORKLIFT T2 DOUBLE PANTOGRAPH User Manual

Page 20

20

6. MAINTENANCE

6.1 Maintenance Devices

NEVER go under a raised lift platform until load is removed and

lift is securely blocked in raised position with maintenance

devices.

Lock-out/tag-out power source.

This procedure describes the only factory-approved method of working under a lift.

Follow these instructions EVERY

1. All loads must be removed from the lift prior to engaging the maintenance devices. These devices are

designed to support an unloaded lift only. Failure to remove the load from the lift prior to blocking could

cause the failure of the maintenance devices and allow the lift to fall unexpectedly. This can result in

personal injury or death.

time you plan to reach or crawl beneath the lift to perform service

or maintenance – no matter how momentary that might be.

If the factory-provided maintenance devices are damaged or missing, stop immediately and

consult the factory for assistance. The manufacturer is not liable for your failure to use the

approved maintenance devices and procedures that have been provided.

2. Raise the lift to its fully raised position. If you do not, the maintenance devices may not be able to be

placed properly in their designed blocking position.

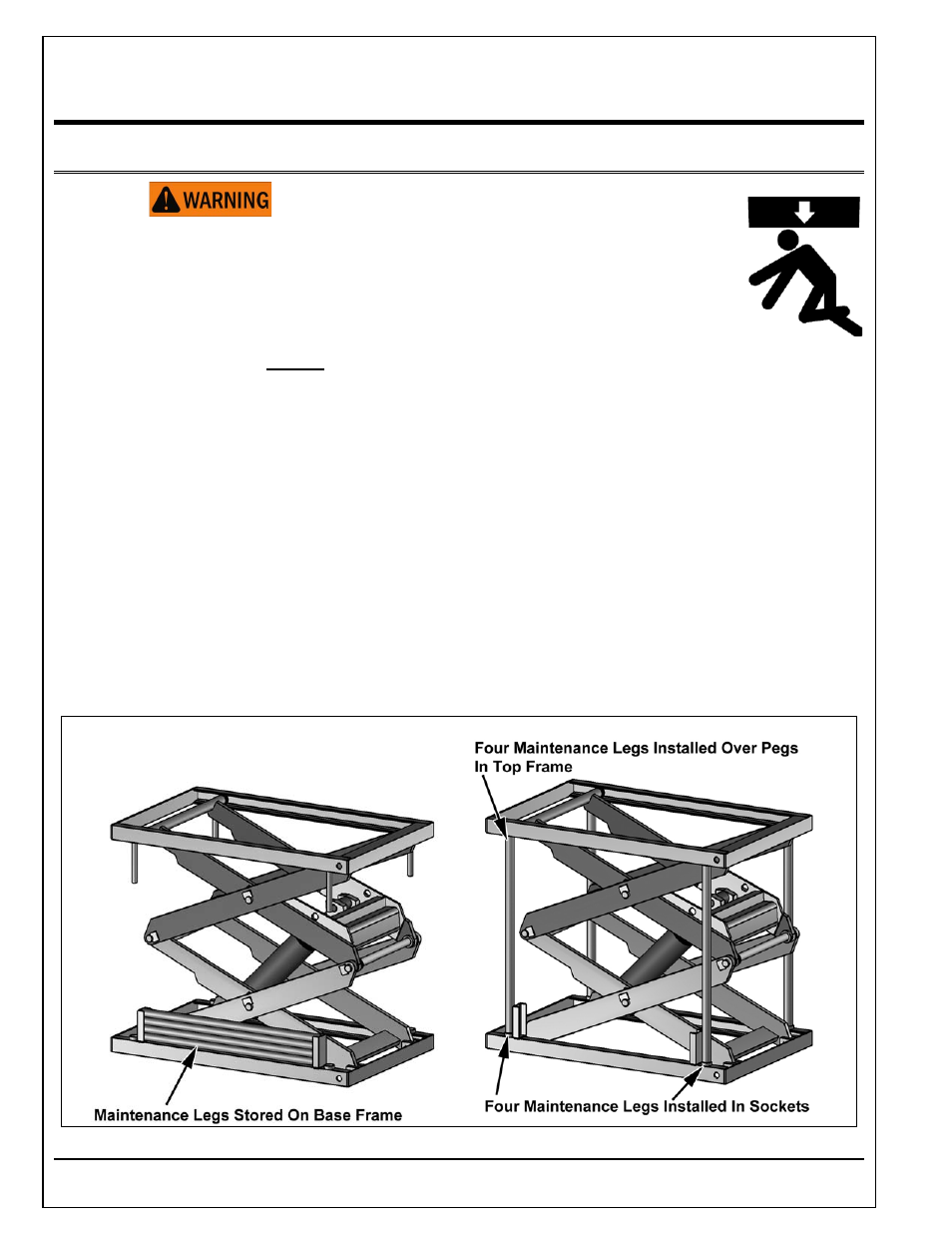

3. The lift will be provided with maintenance legs stored on one of the scissors arms, or with two (2) drop-

in maintenance locks stored on the outside of the base frame. The legs must be placed over pegs in

top frame and within sockets in bottom frame (See Figure 6.1).

Figure 6.1