Autoquip TORKLIFT T2 DOUBLE PANTOGRAPH User Manual

Page 16

16

Verify installation area is clean before starting. Check mounting surface of pit floor with a level or straight

edge. If floor is not level, add shims or grout under entire perimeter of base to achieve a level and flat base

installation. A level base is essential for proper wheel tracking and smooth lift operation.

Prevent serious injury or death.

Depending on model, weight of lift ranges from 1500 – 4450 lbs.

Use a properly rated lifting device to move and install lift.

Lower lift into pit and check for proper height. Lift must be solid and flush with pit angle framing (D). If

needed, shim to desired height. DO NOT “spot” shim. Shim along full length of frame. This will prevent

frame from sagging under load.

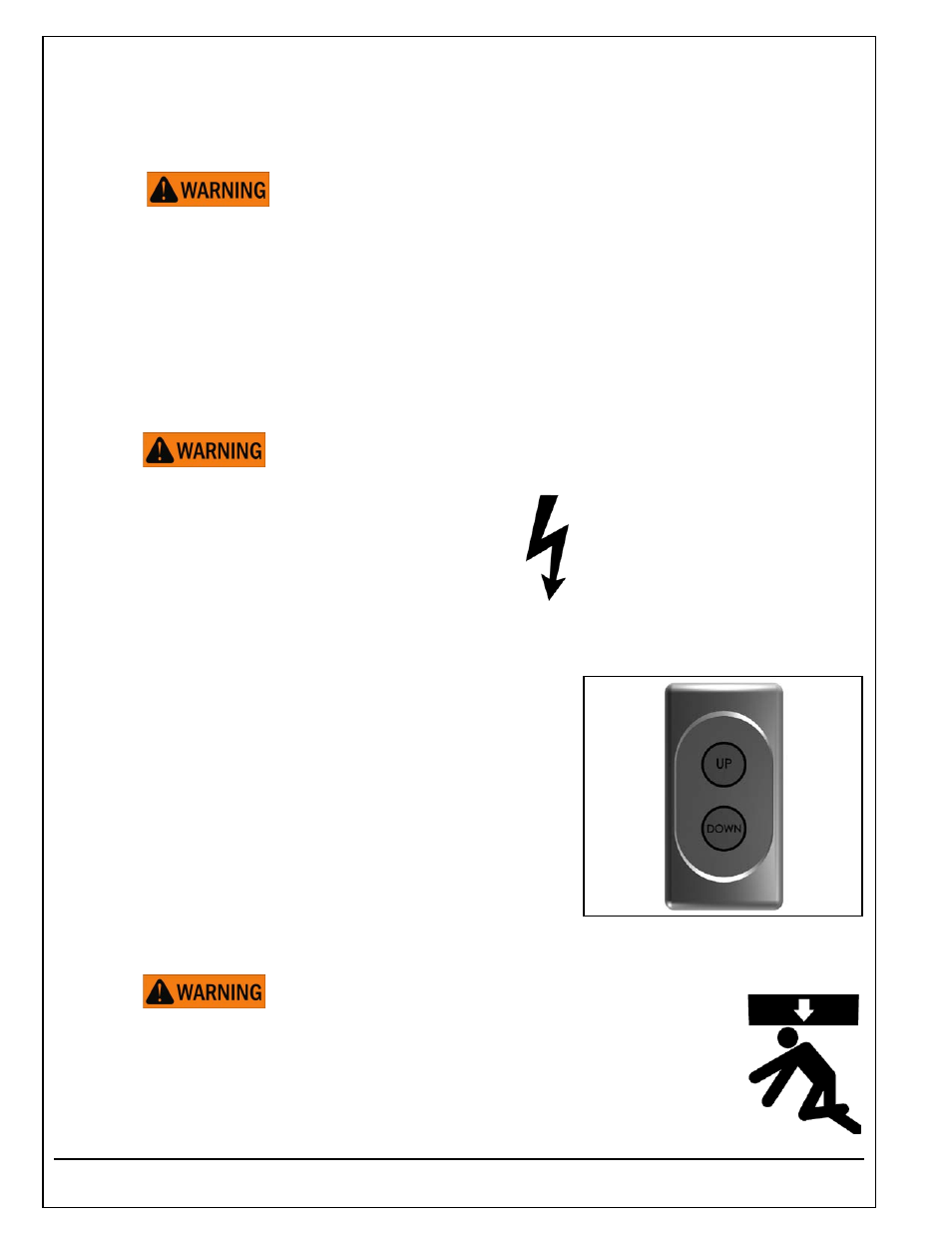

Prevent serious injury or death.

Electrical service installation must be

performed by a

licensed electrician and conform to all

local and national

electrical codes.

NOTE: For larger horsepower motors, consult factory.

Temporarily connect electrical service and hydraulic hoses.

Fill hydraulic reservoir with proper type and volume of fluid.

Press “UP button and raise lift one foot.

Press “DOWN” button to fully lower lift. Continue to hold down

button for 60 seconds. Repeat procedure five to seven times to

bleed air out of hydraulic system.

Raise and lower lift as needed to make positioning adjustments.

Adjust platform to a clearance of 1” minimum around perimeter

between platform and pit angle.

NEVER go under a raised lift platform until load is removed and

lift is securely blocked in raised position with maintenance

devices.

See "Maintenance Device" section of this manual.