APG PT-400 Pressure Transducer user manual User Manual

Page 5

Rev. C,4/13

PT-400

5

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • [email protected]

•

Instructions

All units are factory calibrated prior to shipment.

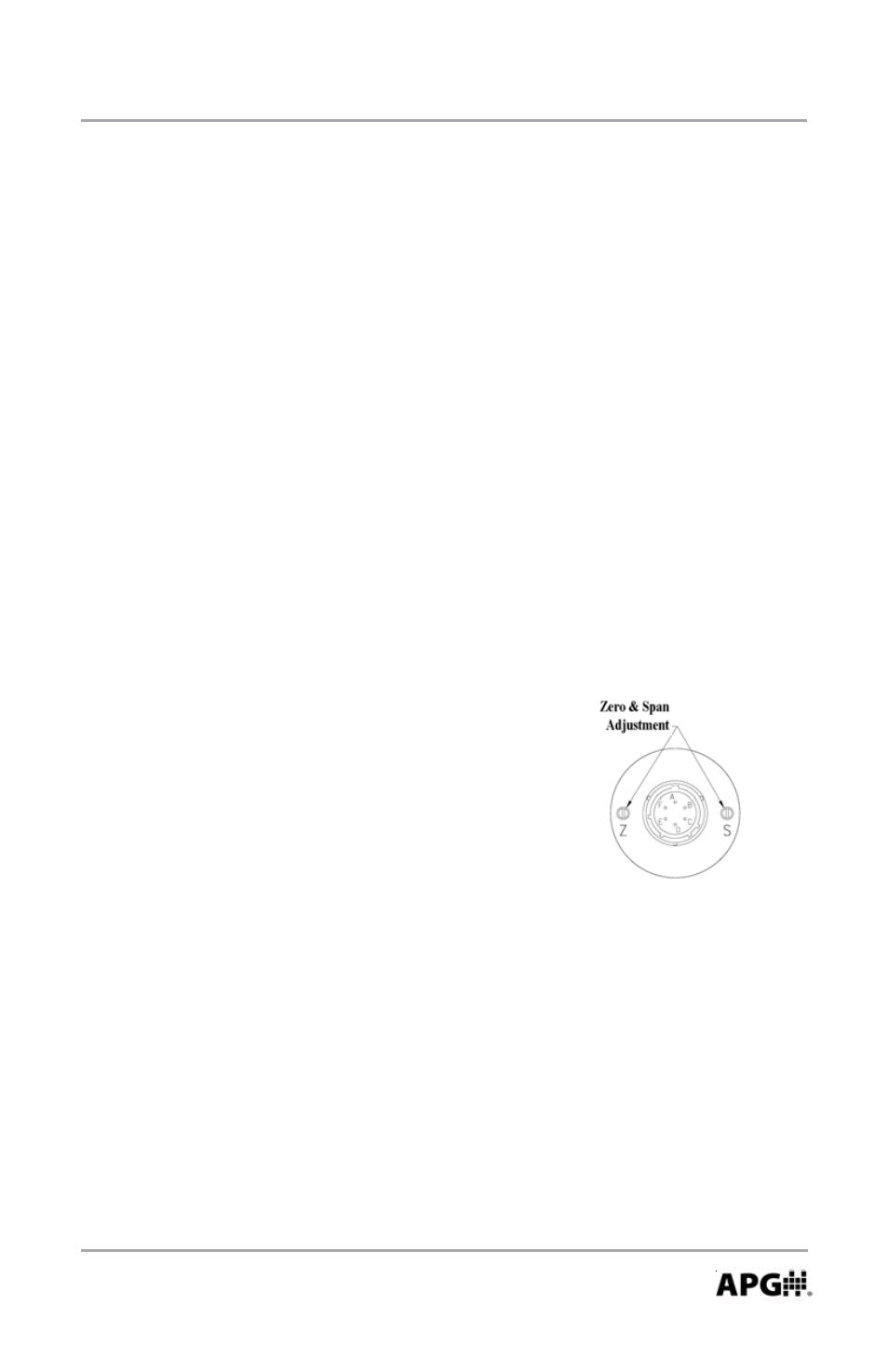

1. Zero Trimming

If it becomes necessary to re-adjust “zero”, this can be accomplished by

adjusting the trimpot marked “Z”. An ideal zero is indicated by an output of

4 mA. (4/20 mA) or 0 (5 VDC, 10 VDC).

A. Remove the protective screw.

B. Ensure that the transducer is at 0 psig or 0 psia (vacuum if absolute)

C. Using a jewelers screwdriver or a suitable instrument, adjust the “Z” pot

until you have 4 mA (4/20 mA) or 0 (5 VDC, 10 VDC) output. Do not make

changes to the Span adjustment (the “S” pot to the right ) as part of the

zero trimming. The Span should only be changed as part of the re-

calibration of a gauge with a known pressure source.

Note: You may also return the transducer to the factory for repair and/or

adjustment.

2. Re-calibration

This procedure requires a known pressure source

of at least ±0.1% accuracy in order to fully utilize the

accuracy potential of the transducer. (If not available,

you can return it to the factory for re-calibration.)

Procedure:

A. Ensure that the transducer is at 0 psig or 0 psia

(vacuum if absolute), and adjust zero as per

instructions in #1.

B. Apply full scale pressure to the pressure port and adjust the span (“S”)

pot until the full scale signal is reached.

C. Re-check zero and re-adjust the zero (“Z”) pot if required.

D. Repeat steps B, and C, until no further adjustment is required.

3. Electrical Information

4/20mA

This device is a 2 wire, loop powered transmitter. A voltage of between 9 and

28 VDC must be maintained at this connection. Completion of the earth or

system ground is recommended for proper circuit protection.

Zero

Adjustment

Span

Adjustment

MAIN PCB ASSEMBLY

S

Z