6 clearing a plugged rotor, 7 replacing the drive belt, 8 greasing – Echo 74554 Owners Manual v.3 User Manual

Page 16

12

5 INCH CHIpper

SERVICE AND MAINTENANCE

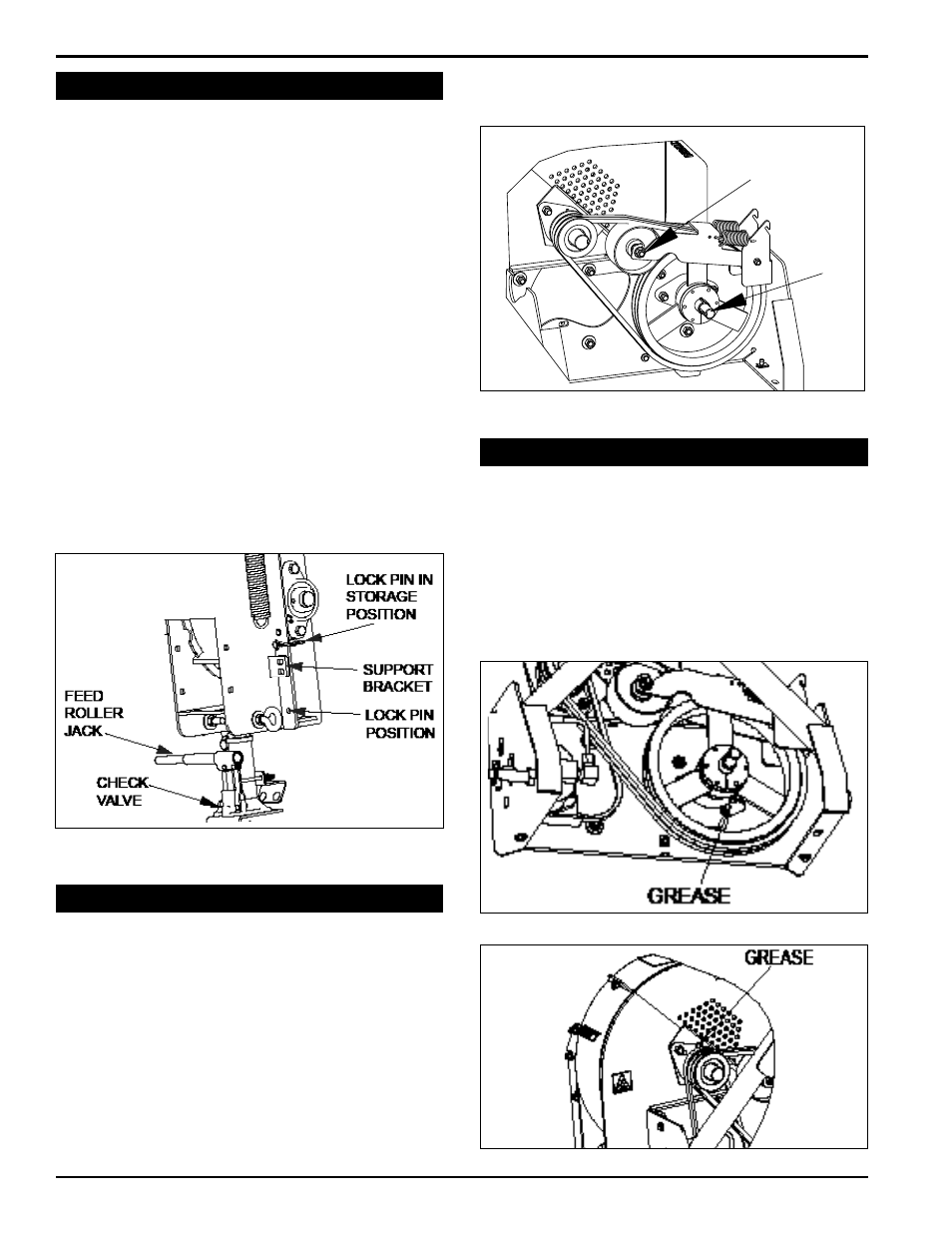

The feed roller lift jack is used to raise the feed roller if chip-

ping material becomes wedged in or behind the feed roller.

To raise the feed roller:

disengage PTO and shut off tractor engine. Wait for

1.

all moving parts to come to a complete stop.

Remove lock pin from storage position (see Fig. 5.4)

2.

Turn check valve clockwise to engage jack pump.

3.

Once the jack is engaged, pump the handle to raise

4.

the feed roller until the lock pin position aligns with

one of the support bracket holes.

Secure the position by putting the lock pin through the

5.

support bracket and lock pin position.

Clear materials out from underneath the feed roller.

6.

Remove the lock pin.

7.

Turn the check valve counterclockwise to disengage

8.

the pump and lower the jack.

Replace lock pin in storage position.

9.

leaving THe

loCK Pin in anY oTHer PosiTion maY inTer-

fere WiTH feed roller oPeraTion.

Check the condition of the drive belt annually or after every

25 hours of operation, whichever comes first. Replace a

cracked, frayed, worn, or stretched drive belt. Only replace

drive belt with original banded type belt, do not use single

type belts. To adjust the drive belt, proceed as follows:

Remove large belt guard by removing five (5) 5/16"

1.

bolts and washers.

Remove the idler pulley by removing the 4" bolt in the

2.

center of the pulley (see Fig. 5.5).

Remove drive belt from pulleys.

3.

Install new belt on pulleys.

4.

Figure 5.5 Belt and pulleys with belt shield removed

5.6 Clearing a Plugged roTor

5.7 rePlaCing THe drive belT

IDLER

PULLEY

JACK

SHAFT

The chipper has grease zerks that must be greased every

50 hours. For their locations, see below:

Two zerks on the jack shaft (remove belt cover

1.

to access).

Two zerks on the rotor shaft (remove belt cover

2.

to access).

Two zerks on the feed roller shaft.

3.

Two universal joints on the PTO driveline.

4.

One grease zerk on the discharge chute.

5.

5.8 greasing

Figure 5.4 Feed roller jack and lock pin

Figure 5.7 Grease zerk on rotor shaft

Figure 5.6 Grease zerk on jack shaft

Put idler pulley back in place and replace bolt.

5.

Replace belt guard.

6.