6 setting blade clearance, 7 clearing a plugged rotor, English – Echo CH5540H Owners Manual v.4 User Manual

Page 17

13

5 INCH CHIPPER

ENGLISH

SERVICE & MAINTENANCE

BEFORE INSPECTING OR SERVICING ANY PART OF THIS MACHINE, SHUT OFF POWER SOURCE,

AND MAKE SURE ALL MOVING PARTS HAVE COME TO A COMPLETE STOP.

WARNING

Figure 5.2 Sharpening the blades

45°

.25

MOUNTING SURFACE

(DO NOT GRIND)

MOUNTING SURFACE

(DO NOT GRIND)

SHARPENED

SURFACE

SHARPENED

SURFACE

The chipping blades should clear the anvil by 1/16 inch to

1/8 inch. Check the clearance every 8 hours of operation

and adjust if needed. The chipping anvil is reversible. All

four sides of the anvil can be used for chipping.

To adjust the anvil:

1. Lift rotor access cover and expose rotor. Loosen the

two 1/2" bolts that hold the chipper anvil to the frame.

2. Measure the amount of clearance between chipping

blade and chipper anvil from inside of housing. The

gap should be 1/16" to 1/8".

3. Adjust inward or outward to desired measurement. Use

the nuts on the adjustment bolt (See Fig. 5.3).

4. Tighten bolts on chipping block to 75 ft. lbs. and resume

operation.

Remove the two bolts holding the anvil and use one of the

other three edges if the chipper anvil edge is damaged or

worn unevenly. Adjust for correct measurement.

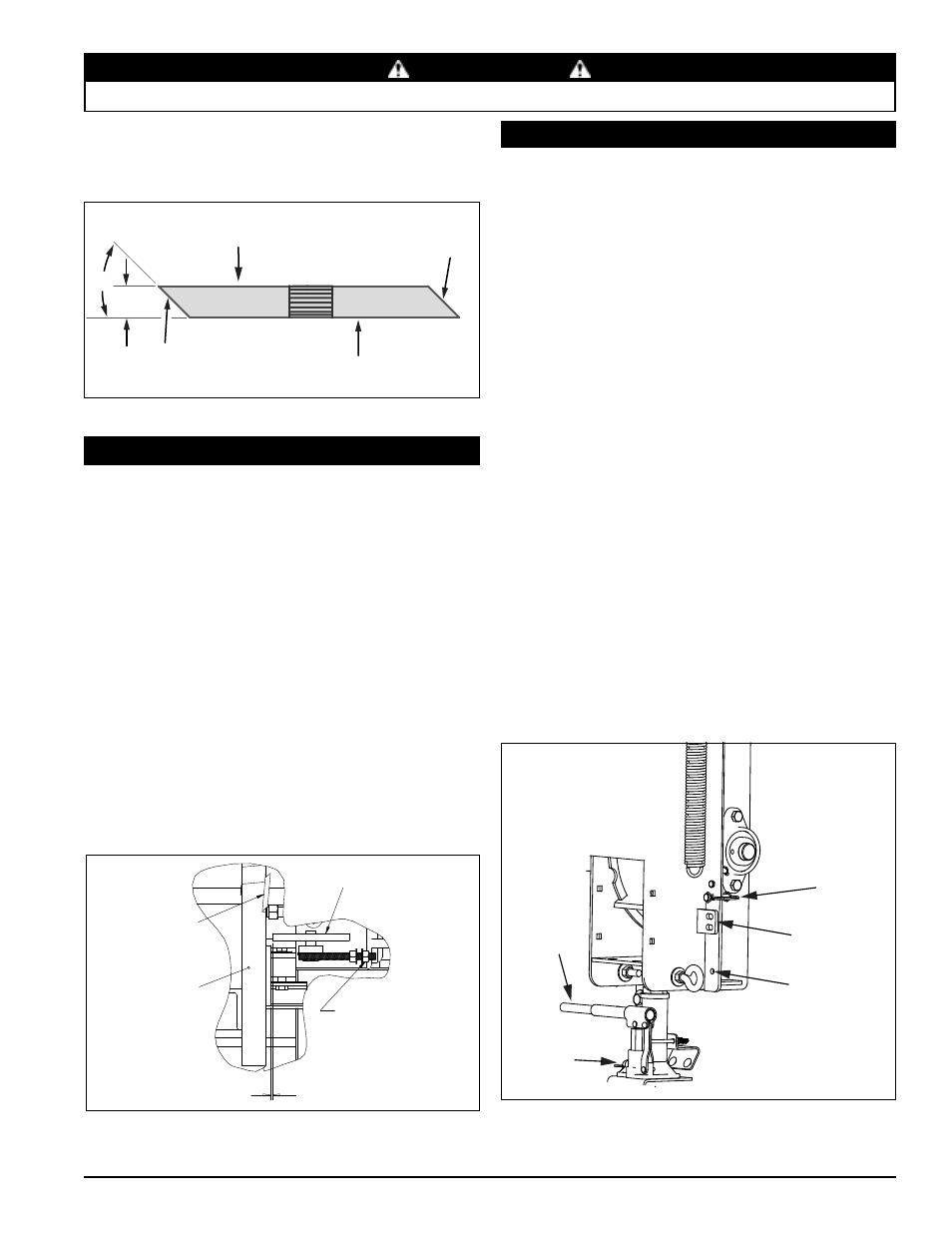

Figure 5.3 Chipper blade and anvil clearance

ROTOR

CHIPPER

BLADE

ANVIL

ADJUSTMENT

ANVIL

1/16" - 1/8"

5.6 SETTING BLADE CLEARANCE

5.7 CLEARING A PLUGGED ROTOR

Figure 5.4 Feed roller jack and lock pin

CHECK

VALVE

FEED

ROLLER

JACK

LOCK PIN IN

STORAGE

POSITION

SUPPORT

BRACKET

LOCK PIN

POSITION

Feeding too large or too much material at once may plug

the chipper. To clear a plugged disk, proceed as follows:

1. Allow all moving parts to come to a complete stop.

2. Remove the two 3/8” retaining bolts holding the access

cover to the chipper frame and lift up access cover.

3. Remove the lock pin from storage position (see

below).

4. Turn check valve clockwise to engage the jack pump.

5. Pump the handle to raise the feed roller until the lock pin

position aligns with one of the support bracket holes.

6. Secure the position by putting the lock pin through the

support bracket and lock pin position.

7. Clean the debris away from the chipper disk. Turn the

disk by hand to be sure it is free to rotate. Be careful

to avoid the chipper blades when cleaning out the

debris.

8. Remove the lock pin and put it back in storage

position. LEAVING THE LOCK PIN IN ANY OTHER

POSITION MAY INTERFERE WITH FEED ROLLER

OPERATION.

9. Turn the check valve counterclockwise to disengage

the pump and lower the jack.

10. Close access cover and replace bolts.

7. For blades that have been repeatedly sharpened,

ensure that the sharpened surface extends past the

chipping slot opening. If it does not extend past the

opening, the blades should be replaced.