Assembly, 1 tires and rims, 2 trailer hitch – Echo CH8720iH Owners Manual v.1 User Manual

Page 10: Non ce compliant (figure 2.1), Ce compliant (figure 2.3), 1 tires and rims 2.2 trailer hitch, Warning

6

8 INCH TURNTABLE CHIPPER

Section

assemBlY

1. Mount tires and rims to the axle using the lug nuts.

2. Attach the fender supports to the trailer using three 1/2

x 3-1/2" hex bolts, washers & nuts.

3. Attach the fenders to the fender supports using four 3/8

x 1" carriage bolts, washers and nuts.

2

2.1 Tires anD rims

2.2 Trailer hiTch

warninG

If any bolts or nuts are dropped in the machine, be sure

to remove them before starting the machine.

1

2

3

4

5

6

6

7

7

8

9

10

11

12

13

14

15

16

17

Figure 2.3, CE Compliant Hitch Assembly

non ce comPlianT (FiGure 2.1)

1. Place hitch pole assembly(8) into the frame, align

mounting holes to desired length and secure using

two 1/2” x 4-1/2” bolts, washers and nuts (hardware

not shown in Figure 2.1). Torque to 75 ft-lbs.

2. Attach coupler mount(7) to hitch pole using two 5/8”

x 4 1/2” bolts(1), washers(2) and centerlock nuts(5).

Torque to 150 ft-lbs.

3. Attach 2" coupler(6) to coupler mount using two 1/2

x 4" bolts(3) and centerlock nuts(4). Torque to 75 ft-

lbs.

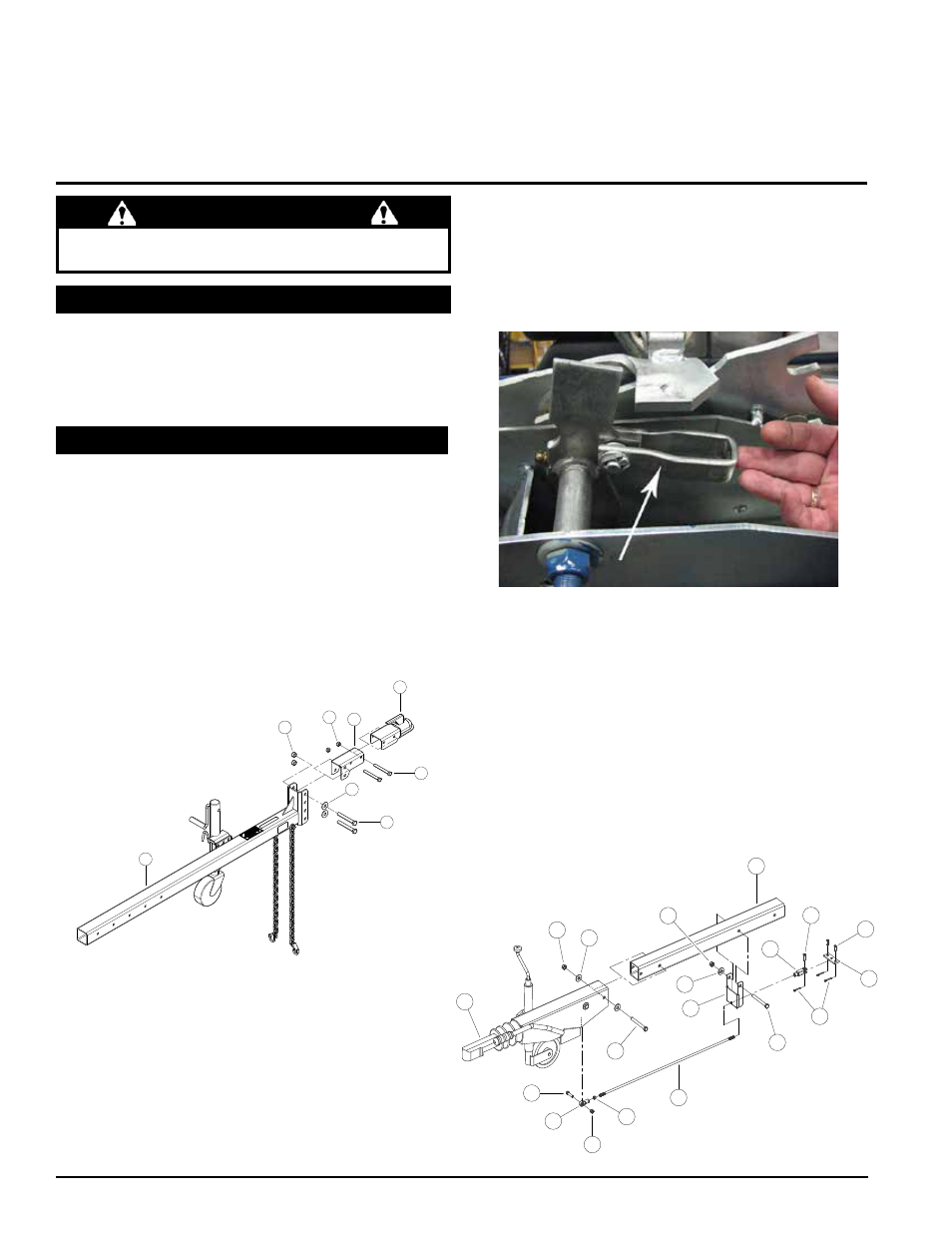

Figure 2.2, Remove this clevis on 50mm coupler

Figure 2.1, Non-CE Compliant Hitch Assembly

1

2

3

4

5

6

7

8

ce comPlianT (FiGure 2.3)

1. Place hitch pole(13) into machine frame. Place one

1/2” x 4 1/2” bolt, washer and centerlock nut through

frame and end hole of hitch pole. Next, align the brake

rod hanger bracket(11) (as shown in figure 2.3) to the

other mouting hole and secure by placing the second

1/2” x 4 1/2” bolt(5) through the frame and hanger

bracket, add washer(6) and centerlock nut(7). Torque

both to 75 ft-lbs.

2. Attach 50mm coupler(4) to hitch pole(13) using two

1/2 x 4" bolts(8), washers(6) and nuts(7). Torque to

75 ft-lbs.

3. Attaching the brake rod(14) to the coupler will require

the removal of the clevis shown in Figure 2.2. Figure

2.2 is an underneath view of the coupler.

4. Route the brake rod(14) through the brake rod hanger

bracket(11). Once routed, thread 3/8 jam nut(17) and

3/8" bearing rod end(9) on to the brake rod. Connect

rod end to the coupler, at the location where the clevis

was removed in step 3. Secure to coupler with 3/8 x 1

1/2" bolt(15) and nylock nut(16).

5. Attach 3/8" adjustable clevis(2) to other end of break

rod. Connect clevis to brake bar plate(12) with 3/8

pin(1) and cotter pin(10).

6. Attach brake bar plate to the brake cables of the

machine with 5/16 pins(3) and cotter pins(10)