4 directing the discharge tube, 5 operating the chipper, Warning – Echo CH8993H Owners Manual v.7 User Manual

Page 17: English

13

8 INCH TURNTABLE CHIPPER

ENGLISH

OPERATION

The disk will continue to turn for some time after the

engine has been shut off. Make sure disk has stopped

completely before inspecting or servicing machine.

NOTE

4.3 ROTATE CHIPPER BASE

1. Limbs fed in to the chipper chute must be 4 inches

10 cm) in diameter or less. Trim side branches that

cannot be bent enough to feed into the chipper chute.

Hold small diameter branches together in a bundle and

feed in simultaneously.

2. ALWAYS run engine at full operating speed before

starting to chip material.

3. Alternate green or fresh cut material with dry

material to lubricate the chipping blades for longer

life and better performance. Chipping dead, dry

material will create heat and dull the chipping blades

quickly.

4. ALWAYS feed brush from the side of the chipper

chute, rather than from the front. Step aside to avoid

being hit by the brush moving into the chipper.

5. ALWAYS place limb, butt end first, into the chipper

chute until it contacts the chipper blades. The actual

feed rate of the limb into the chipper will depend on the

type of material fed and sharpness of the cutting blades.

6. If the engine slows to where it may stall, stop feeding

material and allow the engine to recover. Feed material

more evenly.

7. If the chipper jams, remove the branch and rotate it

before reinserting it into the chute. Alternately insert and

retract the limb or insert continuously at a rate that will

not kill the engine.

8. NEVER use the belt engagement to clear a plugged

rotor. This may cause belt damage. Refer to the

instructions for clearing a plugged rotor in the Service

and Maintenance section.

9. NEVER attempt to clear a plugged rotor or discharge

with the engine running.

ALWAYS shut engine OFF

and remove the spark plug wire before servicing any

part of this machine

10. NEVER attempt to chip pieces of metal, rock, bottles,

cans or other foreign objects.

NEVER disengage the belt as part of the stopping or

shut down process. The belt should remain engaged

during the entire shutdown process.

Leaving the belt engaged is a vital part of proper shut-

down and ensures the rotor stops spinning in con-

junction with the engine shutting off.

TO PROPERLY SLOW DOWN AND STOP THE DISK

AND ENGINE:

1. WITH THE BELT STILL ENGAGED

, SLOWLY move the

throttle to the

SLOW position with the belt still engaged.

2. Allow the engine to run at slow idle for 30-60 seconds.

3. Stop the engine by moving the throttle to the

STOP

position or turning off the ignition switch.

4. Allow disk to come to a complete stop.

5. Once the engine is off and the disk has completely

stopped, the belt can be disengaged by moving the

belt engagement handle back to the

START position.

4.4 SLOWING AND STOPPING THE CHIPPER

DISK AND ENGINE

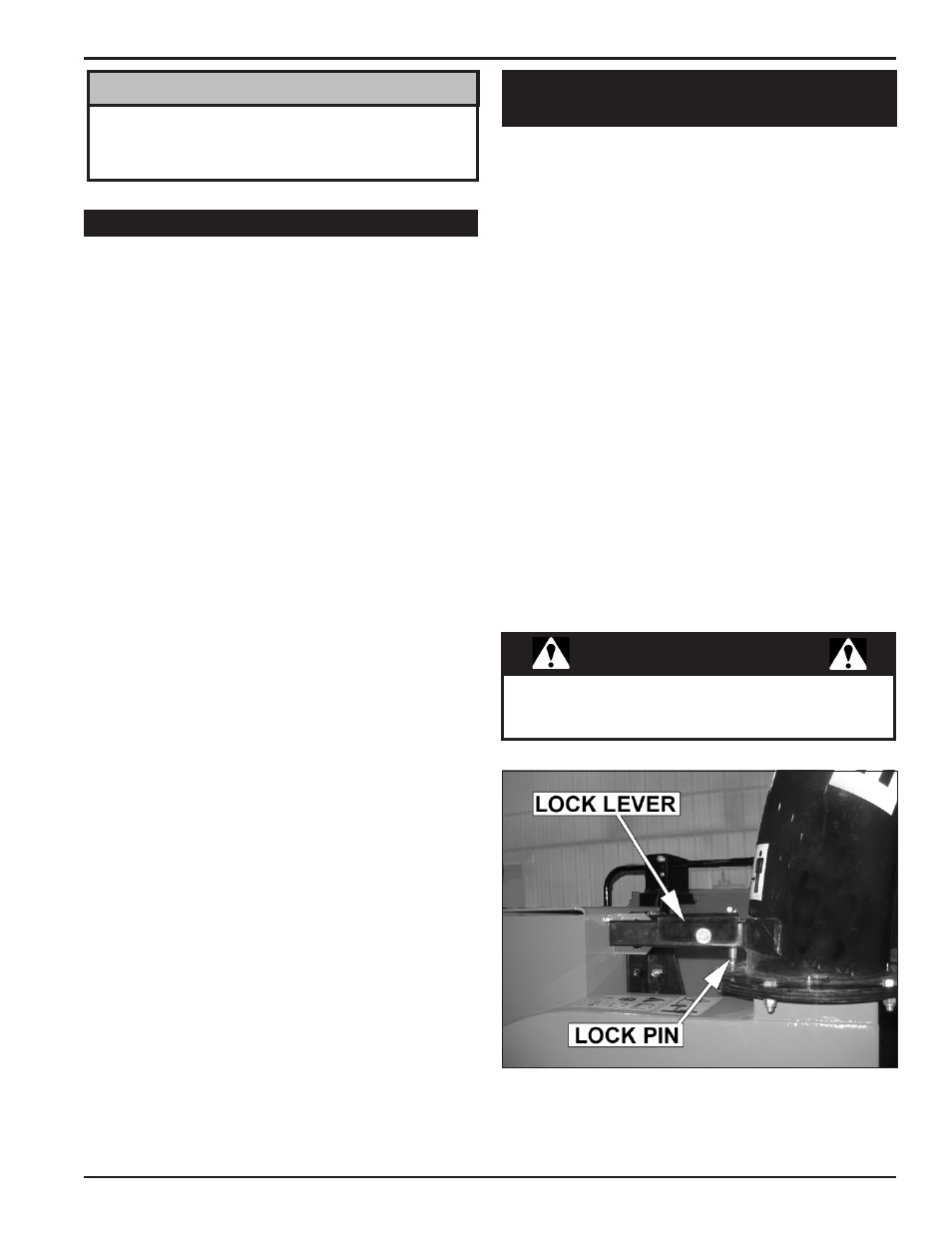

The chipper base must always be locked in place.

Failure to do so may result in machine vibration, seri-

ous bodily injury or death.

WARNING

Figure 4.1 - Directing the Discharge Tube/Cap.