Warning, Feed sensor programming instructions, Step 1. initiating program mode – Echo 72825 Instruction User Manual

Page 4: Step 2. enter low (l = low) rpm, Step 3. enter normal (n = normal) rpm, Step 4. enter high (h = high) rpm, Step 5. enter return (ret = return) rpm

Instruction Sheet

FEED SEnSOr PrOgrAMMIng

InSTrUCTIOnS

STEP 1. InITIATIng PrOgrAM MODE

Hold down the “S” button while turning the engine key to the “on”

position until “L” starts to flash on the LCD.

STEP 2. EnTEr LOW (L = LOW) rPM

The low setting is the RPM speed where the feed roller stops.

The “up” arrow increases the RPM setting, while the “down” arrow

decreases the RPM setting. Setting the speed lower causes the

engine to lug down more before the feed roller stops.

Hold the appropriate (either up or down) arrow until the desired

1.

RPM speed is displayed (Recommend 1375 rpm).

Push the “S” button once with the desired RPM setting displayed

2.

to save.

nOTE: Do not choose a setting equal to or below zero.

STEP 3. EnTEr nOrMAL

(n = nOrMAL) rPM

The normal setting is the RPM speed that the chipper rotor

usually rotates

Hold the appropriate (either up or down) arrow until the desired

1.

RPM speed is displayed (Recommend 1500 rpm).

Push the “S” button once with the desired RPM setting

2.

displayed to save.

STEP 4. EnTEr hIgh (h = hIgh) rPM

The high setting is not needed with this application.

Set to zero to deactivate.

1.

Push the “S” button once with zero displayed to save.

2.

STEP 5. EnTEr rETUrn

(rET = rETUrn) rPM

The return setting is the RPM speed where the feed roller

restarts. The feed roller should restart before the rotor reaches

“normal” RPM to maximize chipper efficiency. Setting the speed

higher allows the engine to recover more before the feed roller

restarts.

Hold the appropriate (either up or down) arrow until the desired

1.

RPM speed is displayed (Recommend 1400 rpm).

NOTE: wHEN APPROACHINg THE END OF A LOg, IT

MIgHT BE NECESSARy TO MANuALLy OvERRIDE

THE AuTOMATIC FEED SENSOR. BE SuRE TO PAy

ATTENTION TO THE ENgINE SPEED AND FEEDINg OF

THE MATERIAL.

WArnIng

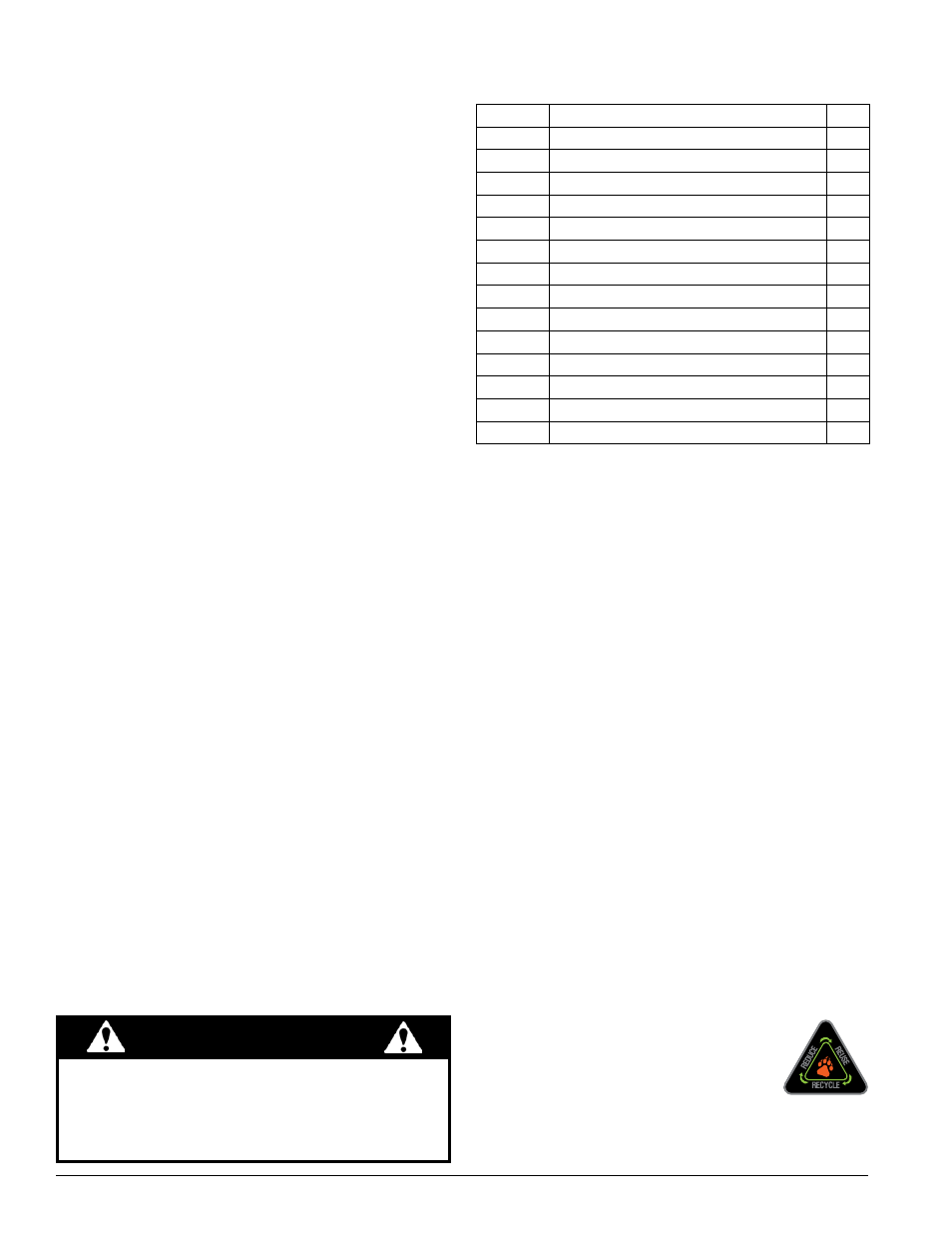

ELECTrOnIC FEED PArTS LIST (Pn 73244)

Pn

DESCrIPTIOn

QTY

12674

CONTROL, LOFA HyDRAuLIC

1

12813

HARNESS, AuTO FEED

1

15602

wASHER, #6 SAE FLAT

4

15640

NuT, M4-0.7 ZP HEX

8

73242-12 BRACKET, PROXIMITy SENSOR

1

12828

CONNECTOR, #10 INSuLATED RINg

2

12829

CONNECTOR, #10 INSuLATED FORK

3

12830

CONNECTOR, .25 INSuLATED MALE

2

17320

STRAP, NyLON TIE-11”

4

16967

vALvE, SOLENOID CARTRIDgE

1

16968

COIL, SOLENOID vALvE

1

73243

INSTRuCTIONS, AuTO FEED

1

15282

BOLT 5/16*1 1/2 gR5 HEX CPS ZP

1

15225

SCREw, #10 X 3/4 HEX TAP SC

1

EChO BEAr CAT

www.bearcatproducts.com

237 Nw 12th Street, west Fargo, ND 58078-0849

Phone: 701.282.5520 • Toll Free: 800.247.7335 • Fax: 701.282.9522

E-mail: [email protected] • [email protected]