Cylinder disassembly, Cylinder disassembly -18 – JLG 19BD Service Manual User Manual

Page 40

SECTION 2 - SERVICE PROCEDURES

2-18

– JLG Lift –

3121154

Cylinder Disassembly

1. Before disassembling the cylinder, clean away all

dirt and foreign substances from openings, particu-

larly the head area.

NOTE: Always protect the chrome surface of the cylinder

rod during assembly and disassembly. Any damage

to this surface will require replacement of the rod.

2. Extend the rod until the piston bottoms out against

the cylinder head.

3. Compress the head retraining ring enough to allow

the the cylinder head to be removed.

4. Carefully slide the head/rod/piston assembly out of

the cylinder tube. A gentle tap on the head assembly

may be required to remove the head from the cylin-

der tube.

5. Place the head/rod/piston assembly on a surface

that will not damage the chrome.

6. Remove the piston locknut and separate the piston

from the rod.

7. Slide the head off the rod from the piston end.

NOTE: When removing the old seals use only blunt tools, be

sure there are no sharp edges that may damage the

seal grooves during removal. Scratching the groove

may cause by-pass.

8. Remove and discard all old seals.

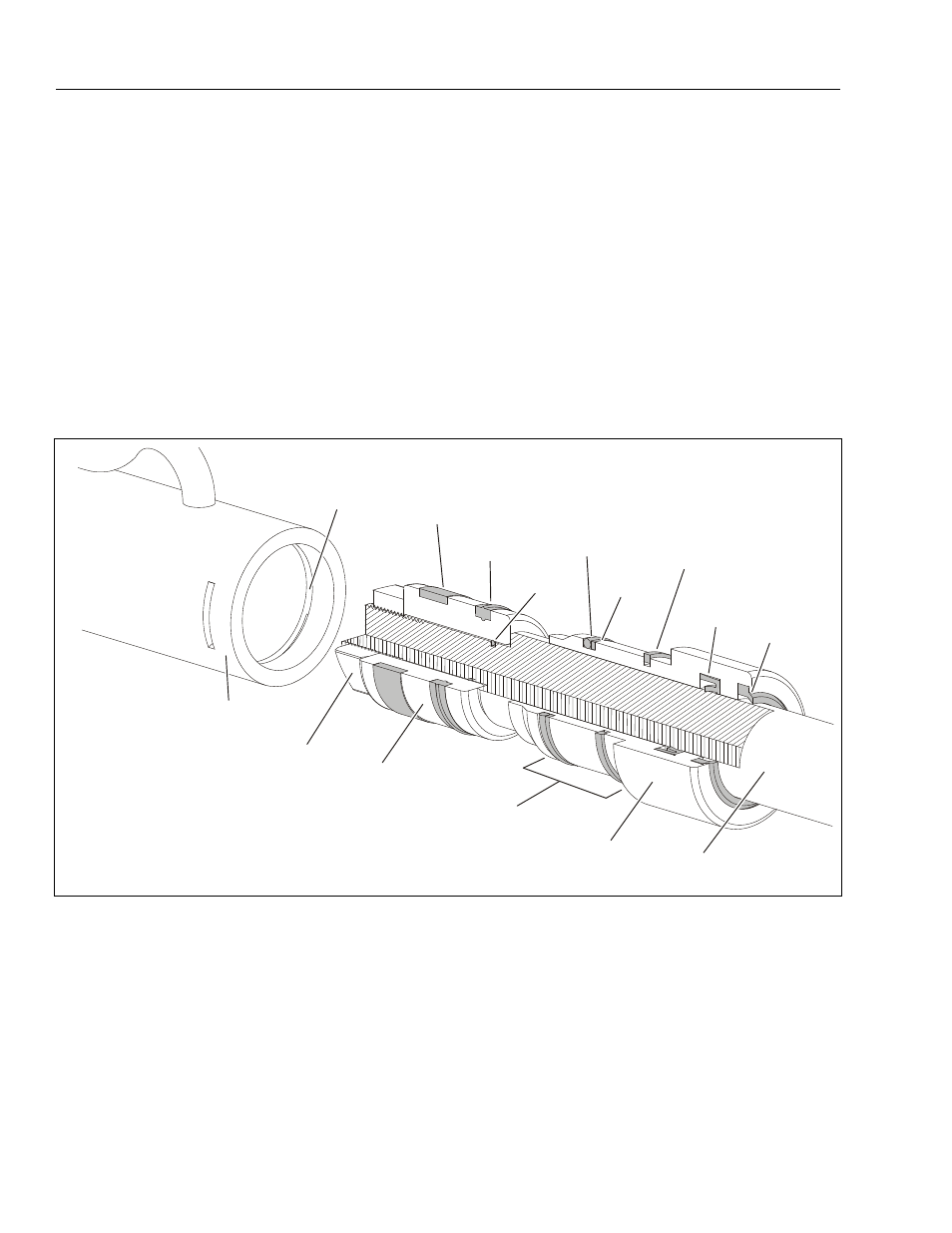

Figure 2-3. Lift Cylinder Internal Component Assembly Cross-Section.

PISTON

LOCKNUT

(Torque

175-200 Ft. Lb.)

WEAR

RING

PISTON

SEAL

O-RING

O-RING

BACKUP

RING

CYLINDER

HEAD

RETAINING

RING

RETAINING RING

GROOVE

ROD

SEAL

ROD

WIPER

CYLINDER

HEAD

WHEN ASSEMBLING

CYLINDER

APPLY ANTI-SEIZE

COMPOUND

AROUND THE HEAD

IN THIS AREA ONLY

CYLINDER

TUBE

ASSEMBLY

CYLINDER

ROD