Worn parts – JLG X550AJ Operator Manual User Manual

Page 116

SECTION 6 - GENERAL SPECIFICATIONS AND OPERATOR MAINTENANCE

6-14

– JLG Lift –

3128791

Tightening of the track

• Connect a grease gun to grease valve 2 and add grease

until belt tension is within the specified values.

NOTE: If the track does not return to the specified values by

following the above procedure immediately discon-

tinue use and contact service personnel.

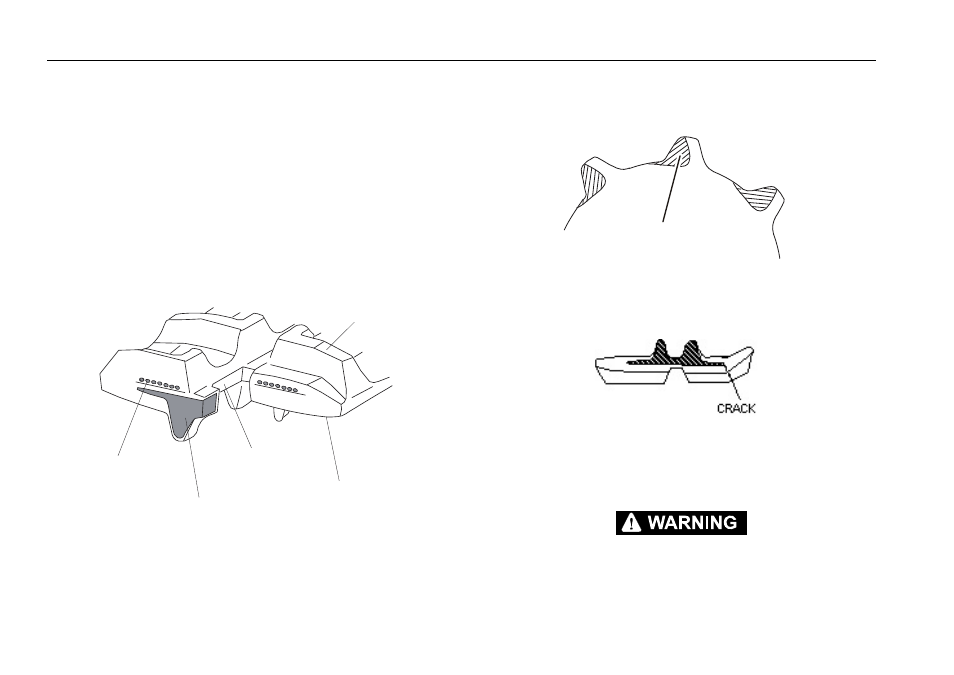

Checking the rubber tracks

• If broken steel ropes are noted discontinue use until

damaged components are replaced

• If broken metal cores are noted discontinue use until

damaged components are replaced

• If metal cores are separating discontinue use of the

machine until the damaged components are replaced.

• If abrasive or fatigue cracks are noted it is recommended

the machine be removed from service until the compo-

nents are replaced.

Track Torque

It is extremely important to apply and maintain proper track

mounting torque.

TRACK NUTS MUST BE INSTALLED AND MAINTAINED AT THE

PROPER TORQUE TO PREVENT LOOSENING OF THE TRACK, BRO-

KEN STUDS, AND POSSIBLE DANGEROUS SEPARATION OF THE

TRACK FROM THE TEETH.

&'()*

)+%&&,%,'

-&./0.(%

/%0'$(.'0%

'('$(.'0%

)*10%0%

%1,2%$2*0%//,&%

CARVED PROFILE

STEEL ROPES

METAL CORE

SPROKET

HOLE

WHEEL SIDE

Worn Parts