Assuming normal wear, Adjustment – JLG 450AJ ANSI Service Manual User Manual

Page 99

SECTION 2 - PROCEDURES

3120749

– JLG Lift –

2-81

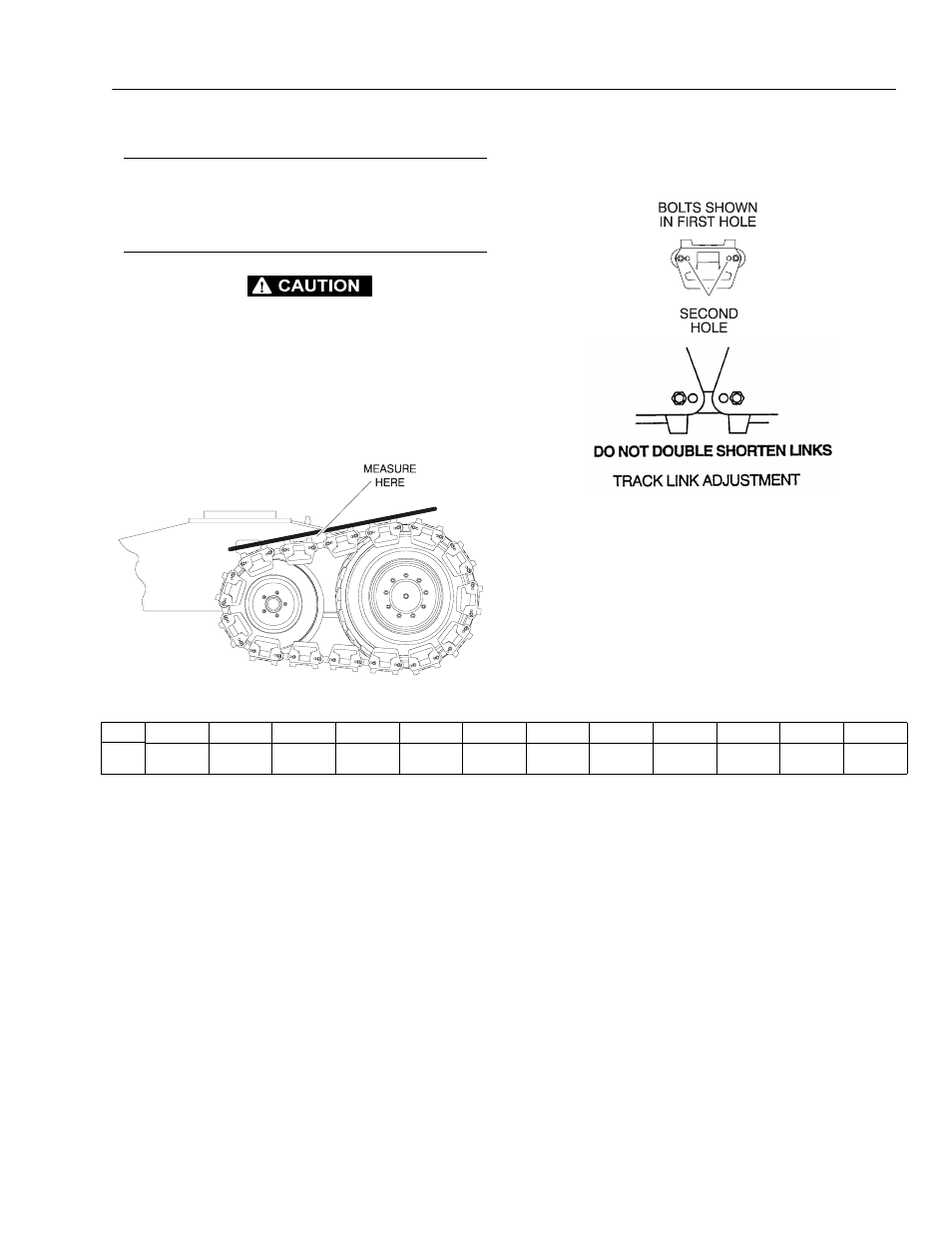

Assuming Normal Wear

It is normal for the bushing to wear down to the bolt and

for the link hole to wear oblong till it is ready to break out

the end.

Adjustment

IMPROPER SLACK ADJUSTMENT COULD CAUSE TRACK PARTS

TO BREAK.

Place a straight edge long enough to reach from the idler

to the drive wheel on the tracks. Measure the maximum

amount of track sag from the high point of the track seg-

ment to the bottom of the straight edge. Properly adjusted

track will have approximately 1 to 2 inches (25 to 50 mm)

slack.

To adjust the slack measurement, move the bolts from the

first hole to the second to create less slack, or from the

second to the first to create more slack.

Table 2-6.Adjustment Chart

Move

1 Hole

2 Holes

3 Holes

4 Holes

5 Holes

6 Holes

7 Holes

8 Holes

9 Holes

10 Holes

11 Holes

12 Holes

Equals

0.81 in

(20.5 mm)

1.62 in

(41 mm)

2.43 in

(62 mm)

3.25 in

(82.5 mm)

4.06 in

(103 mm)

4.87 in

(124 mm)

5.68 in

(144 mm)

6.50 in

(165 mm)

7.31 in

(186 mm)

8.12 in

(206 mm)

8.93 in

(227 mm)

9.75 in

(248 mm)