JLG 660SJ Service Manual User Manual

Page 22

SECTION 1 - SPECIFICATIONS

1-4

– JLG Lift –

3120840

Platform Rotate: Platform level and completely rotated

one direction. Rotate the opposite direction, Record Time.

Rotate the other direction, Record Time.

Articulating Jib: Platform level and centered with the

boom. Start with the Jib down. Jib Up, Record Time. Jib

Down, Record Time.

Test Notes

1.

Stop watch should be started with the function, not

with the controller or switch.

2.

All speed tests are run from the platform. These

speeds do not reflect the ground control operation.

3.

The platform speed knob control must be at full

speed (turned clockwise completely).

4.

Function speeds may vary due to cold, thick hydrau-

lic oil. Test should be run with the oil temperature

above 100° F (38° C).

5.

Some flow control functions may not work with the

speed knob clicked into the creep position.

1.5

TORQUE REQUIREMENTS

Table 1-1. Function Speeds (In Seconds)

Function

600S

600A

Lift Up

46-60

26-32

Lift Down

33-43

26-32

Swing Right & Left*

79-101

79-101

Telescope Out

50-67

35-50

Telescope In

25-33

22-30

Platform Rotate Right & Left**

16-25

16-25

Jib Up

22-34

22-34

Jib Down

16-26

16-26

Lower Lift Up

N.A.

37-50

Lower Lift Down

N.A.

28-38

Lower Telescope Out

N.A.

15-23

Lower Telescope In

N.A.

09-15

Drive Forward & Reverse (2WD)

28-33

35-42

Drive Forward & Reverse (4WD)

31-37

31-37

Drive Above Horizontal - Forward &

Reverse (2WD & 4WD)

43-136

43-136

Drive Horizontal - Forward & Reverse

N.A.

84-70

*Max 10% Difference Between Left & Right

**Max 15% Difference Between Left & Right

4150130 -E

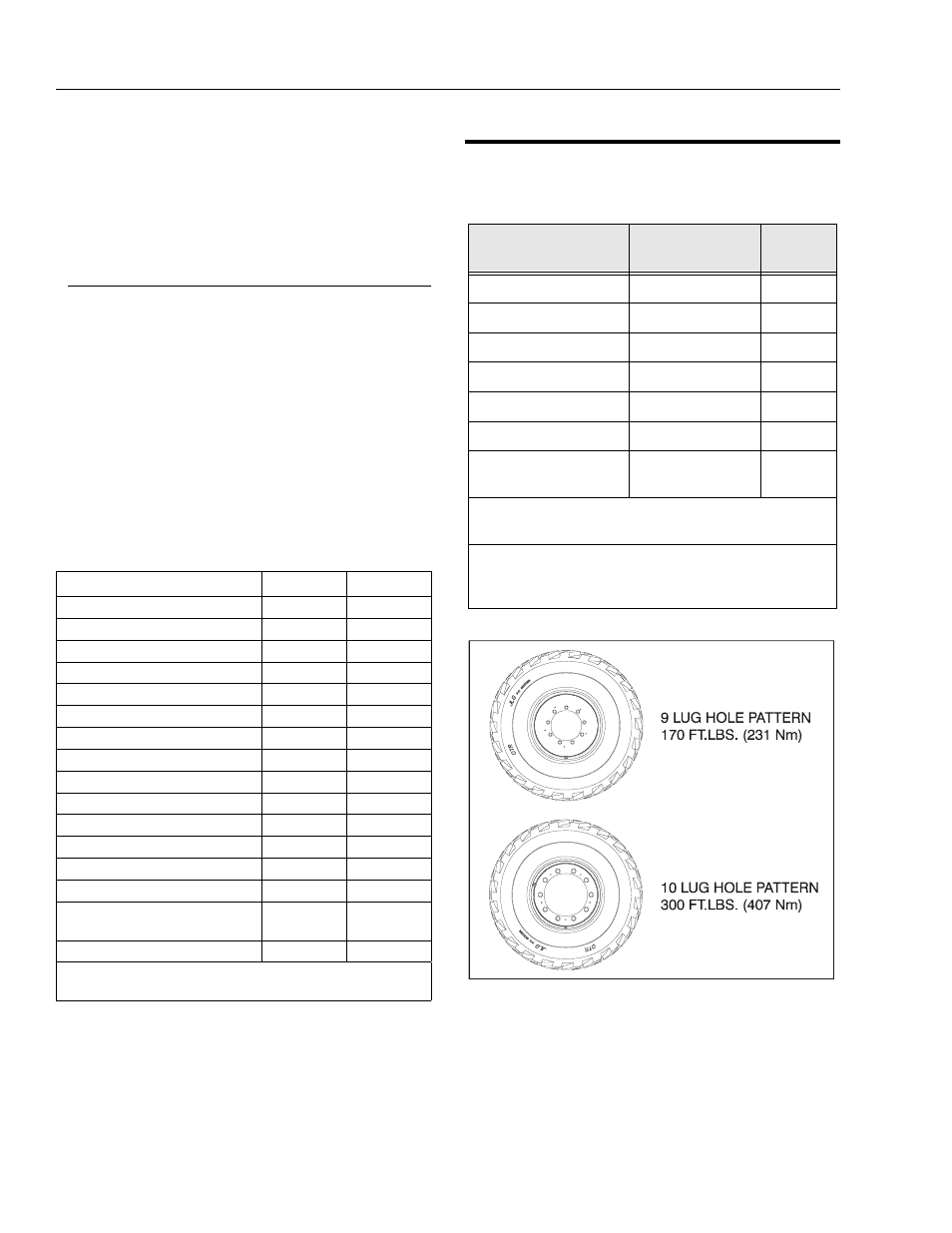

Table 1-2. Torque Requirements

Description

Torque Value

(Dry)

Interval

Hours

Bearing To Chassis

See Note

50/600*

Bearing To Turntable

See Note

50/600*

Wire Rope

15 ft. lbs (20 Nm)

150

Wheel Lugs (S Models)

see Figure 1-1.

150

Wheel Lugs (A Models)

170 ft. lbs. (231 Nm)

150

Engine Mounting Bolts

165 ft. lbs. (231 Nm)

A/R

Engine Manifold Mounting

Bolts

30 ft. lbs. (42 Nm)

A/R

*Check swing bearing bolts for security after first 50 hours of operation

and every 600 hours thereafter. (See Swing Bearing in Section 3.)

NOTE: When maintenance becomes necessary or a

fastener has loosened, refer to the Torque Chart

to determine proper torque value.

Figure 1-1. 600S Lug Torques