11 drive card setup procedures – JLG 660SJ Service Manual User Manual

Page 130

SECTION 4 - BOOM & PLATFORM

4-28

– JLG Lift –

3120840

3.

Install new seals (11), back-up ring (12), cap bearing

(13), bearing packing (14) and thrust ring (10) on

end cap (5).

4.

Place the actuator in the vertical position, install the

piston sleeve (3) in timed relation to the housing (1).

DO NOT MISALIGN THE SLEEVE TOO MUCH ANY ONE WAY, AS IT

WILL MARK THE CYLINDER BORE.

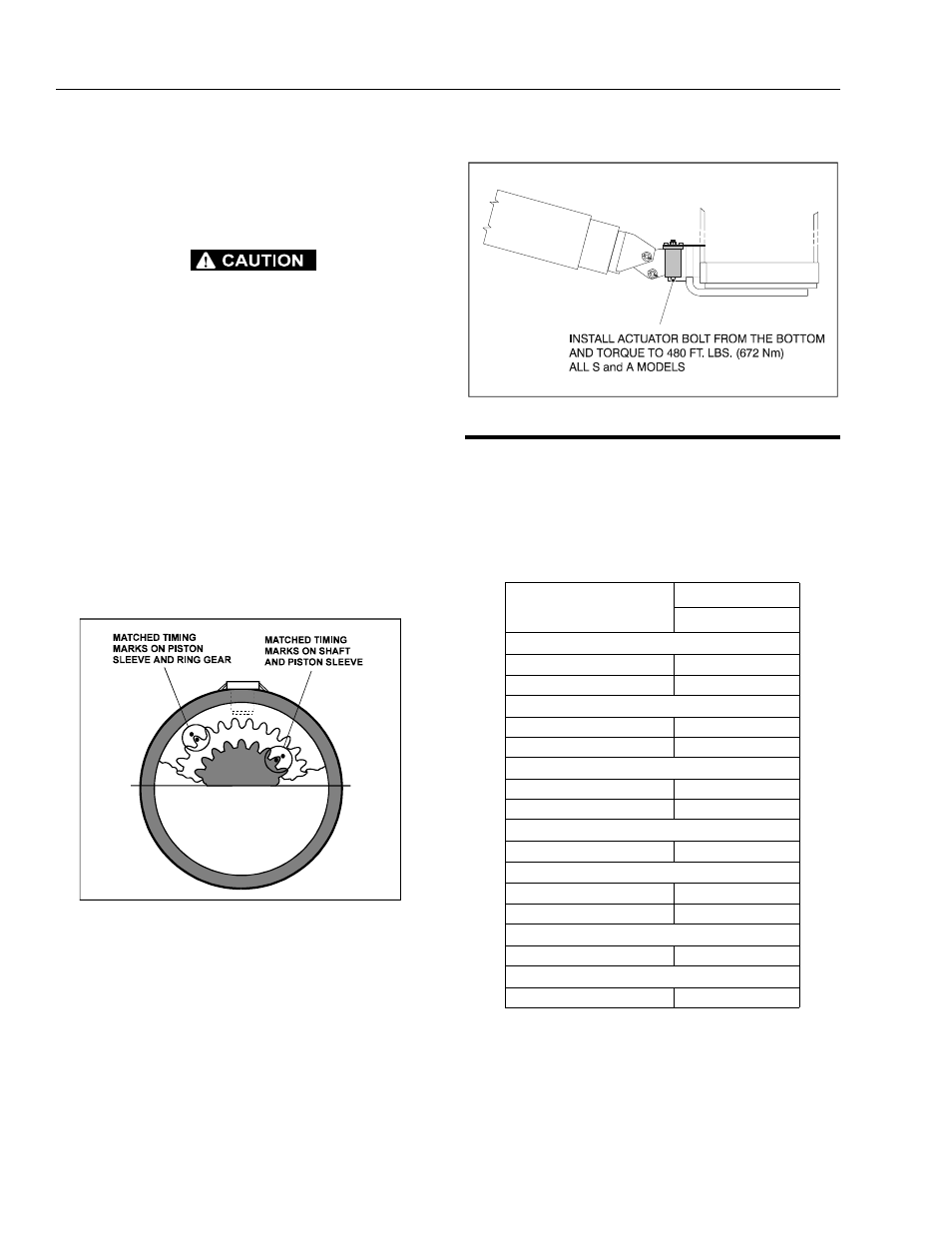

NOTE: The timing marks (the small punch marks on the

face of each gear), must be aligned for proper shaft

orientation. (See Actuator Timing.)

5.

Install the shaft (2) into housing (1) by aligning the

proper punched timing marks. (See Actuator Tim-

ing.)

6.

Temporarily tape the threaded portion of the shaft

will help installation past the shaft seals (masking

tape).

7.

The end cap (5) is torqued to 54 - 68 Nm, such that

the actuator begins rotation at approximately 6.9 Bar

pressure.

8.

The end cap must be secured against the shaft by

installing axial set screws (4).

4.11 DRIVE CARD SETUP PROCEDURES

NOTE: The following procedures are to be used as a begin-

ning basis for controller adjustment. After completing

the procedure, final adjustments are to be made

based on the machines function speed.

Figure 4-35. Actuator Timing

Table 4-1. Function Speeds

Function

Function Speed

In Seconds

Telescope

Extend

48-61

Retract

24-32

Lift

Up

46-60

Down

33-43

Articulating Jib Boom

Up

22-29

Down

16-22

Swing Speed

Full 360°

79-101

Platform Rotation

Left

22-30

Right

22-30

Drive Speed (2WD)

28-32 @ 200ft.

Drive Speed (4WD)

32-36 @ 200ft.