JLG 19AMI Service Manual User Manual

Page 32

SECTION 2 - SERVICE PROCEDURES

2-18

– JLG Lift –

3121190

event that an unacceptable condition occurs, the head

should be replaced.

Piston

Visually inspect the outside surface for scratches or pol-

ishing. Deep scratches are unacceptable. Polishing indi-

cates uneven loading and when this occurs, the diameter

should be checked for out-of-roundness. If out-of-round-

ness exceeds 0.007", this is unacceptable. Check the con-

dition of the dynamic seals and bearings looking

particularly for metallic particles embedded in the bearing

and in the piston seal surface. Remove the seals and

bearings. Damage to the seal grooves, particularly on the

sealing surfaces, is unacceptable. In the event that an

unacceptable condition occurs, the piston should be

replaced.

Tube Assembly

Visually inspect the inside bore for scratches and pits.

There should be no scratches or pits deep enough to

catch the fingernail. Scratches that catch the fingernail but

are less than 0.5 inch long and primarily in the circumfer-

ential direction are acceptable provided they cannot cut

the piston seal. The roughness of the bore should be

between 10 and 20 µ inches RMS. Significant variation

(greater than 8 µ inches difference) are unacceptable. In

the event that an unacceptable condition occurs, the tube

assembly should be repaired or replaced.

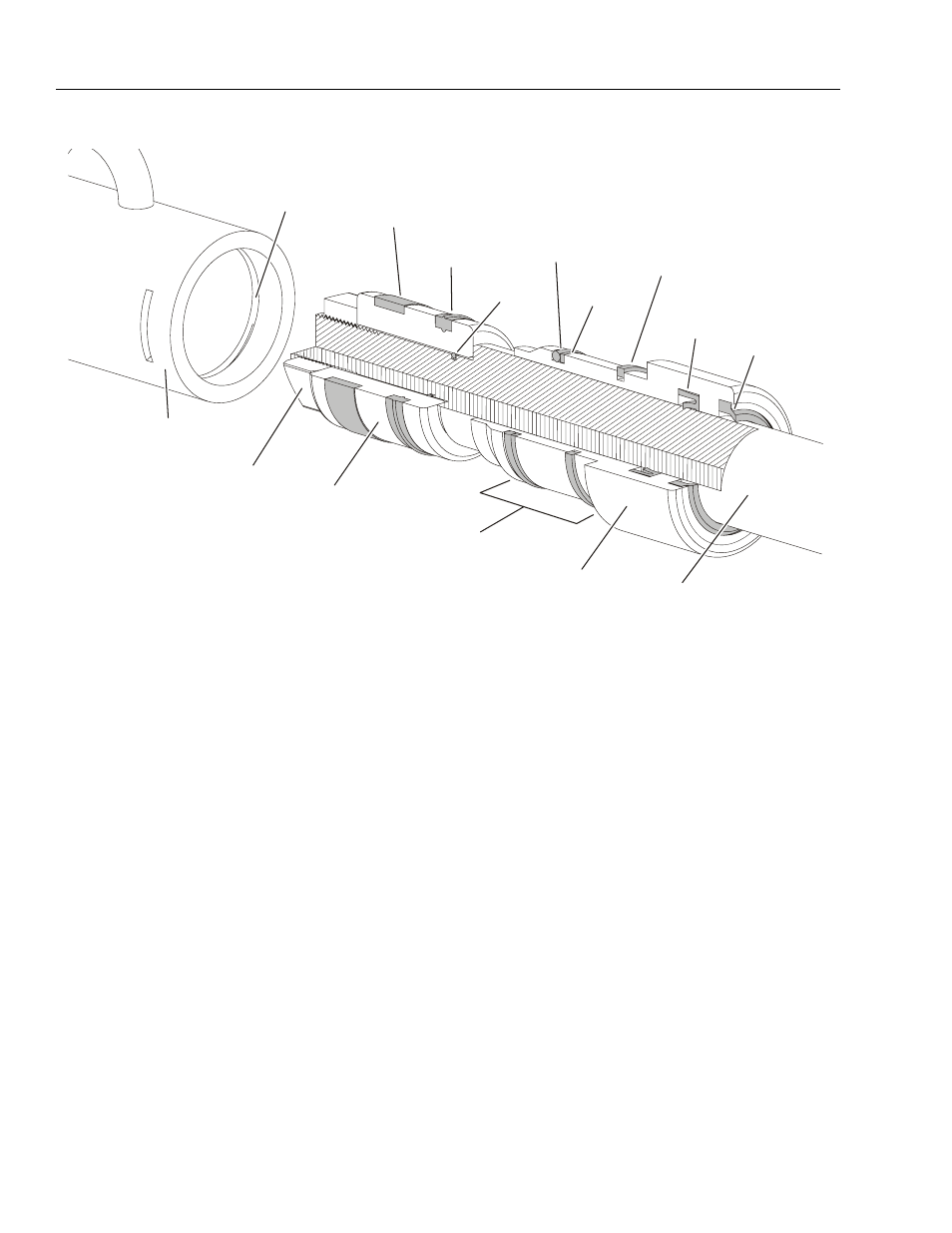

Figure 2-1. Lift Cylinder Internal Component Assembly Cross-Section.

PISTON

LOCKNUT

(Torque

175-200 Ft. Lb.)

WEAR

RING

PISTON

SEAL

O-RING

O-RING

BACKUP

RING

CYLINDER

HEAD

RETAINING

RING

RETAINING RING

GROOVE

ROD

SEAL

ROD

WIPER

CYLINDER

HEAD

WHEN ASSEMBLING

CYLINDER

APPLY ANTI-SEIZE

COMPOUND

AROUND THE HEAD

IN THIS AREA ONLY

CYLINDER

TUBE

ASSEMBLY

CYLINDER

ROD