JLG 20VP (3120848) Operator Manual User Manual

Page 15

SECTION 2 - PREPARATION AND INSPECTION

3120848

– JLG Lift –

2-3

when using the machine for spraying paint or any material

which could cover these surfaces and reduce legibility.

Operation and Safety Manual

Ensure a copy of manual is enclosed in the manual stor-

age box.

Lubrication

For those parts pointed out in the Walk-Around Inspection

requiring lubrication, refer to the Lubrication Chart, Figure

2-4., for specific time interval requirements.

2.5

DAILY FUNCTIONAL CHECK

TO AVOID INJURY DO NOT OPERATE A MACHINE UNTIL ALL

MALFUNCTIONS HAVE BEEN CORRECTED. USE OF A MALFUNC-

TIONING MACHINE IS A SAFETY VIOLATION.

Once the Walk-Around Inspection is complete, a Func-

tional Check of all systems should be performed in an

area free of overhead and ground level obstructions. Per-

form a Functional Check in accordance with the following

procedures:

Set-up machine for operation, according to instructions in

Section 4-3, “Machine Operation”.

Ground Controls

1.

With key switch turned to GRND position (clock-

wise), operate the platform up and down switch

(located in lower access hole with hydraulic fluid res-

ervoir). Raise and lower platform .5m to 1m (2 ft. to 3

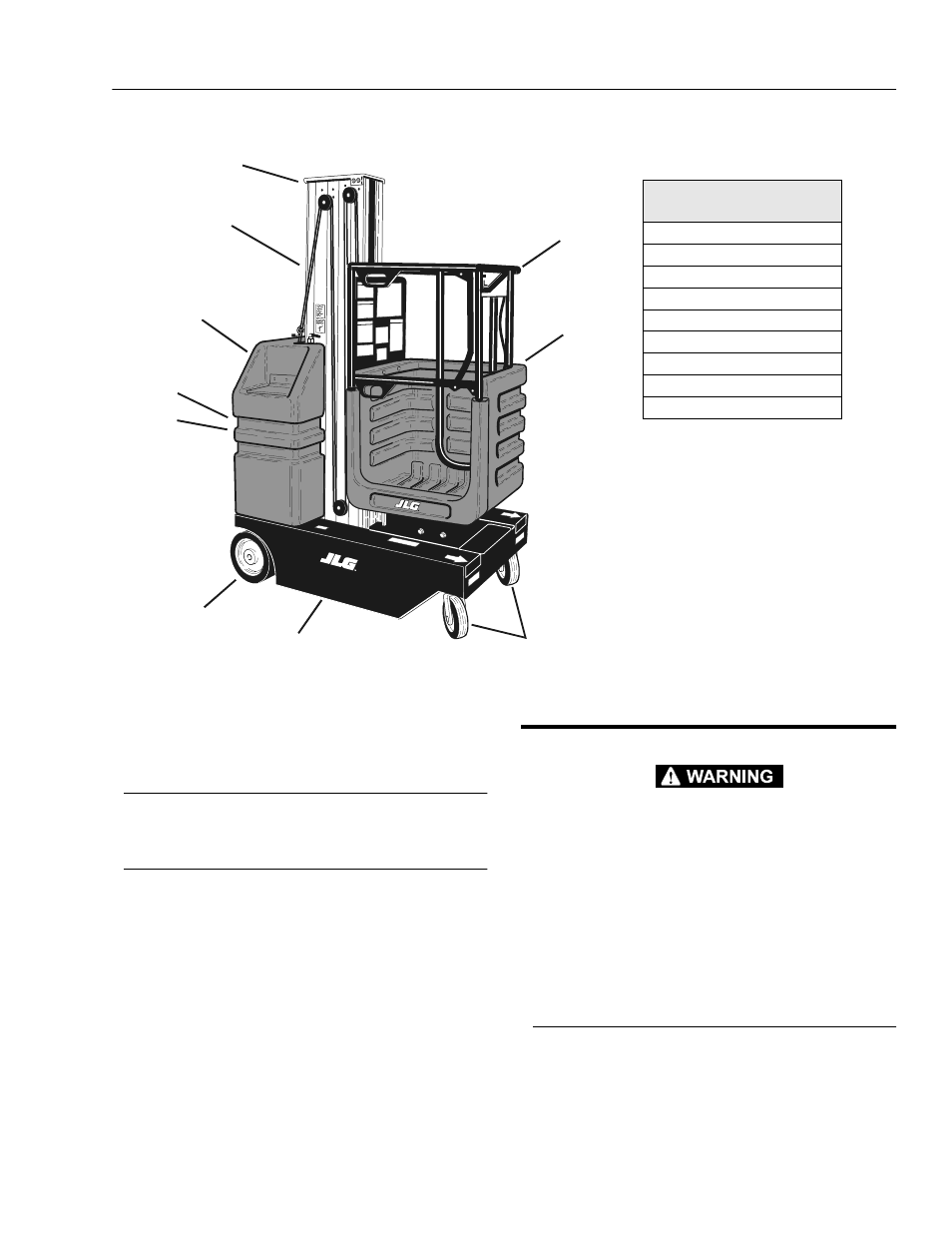

Figure 2-1. Daily Walk-Around Inspection.

1

1

2

3

4

5

6

7

8

9

Daily Walk-Around

Inspection Items

1. Drive and Castor Wheels

2. Base Frame

3. Battery/Battery Charger

4. Motor/Pump/Reservoir Unit

5. Ground Controls

6. Mast Assembly

7. Manual Brake ReleaseControl

8. Platform Assembly

9. Platform Controls