5 torque requirements, 6 lubrication hydraulic oil, Lubrication specifications – JLG 450AJ Service Manual User Manual

Page 10

SECTION 1 - SPECIFICATIONS

1-2

– JLG Lift –

3120869

1.5

TORQUE REQUIREMENTS

* Check swing bearing bolts for security after first 50

hours of operation and every 600 hours thereafter.

1.6

LUBRICATION

Hydraulic Oil

NOTE: Hydraulic oils must have anti-wear qualities at least

to API Service Classification GL-3, and sufficient

chemical stability for mobile hydraulic system ser-

vice. JLG Industries recommends Mobilfluid 424

hydraulic oil, which has an SAE viscosity index of

152.

NOTE: When temperatures remain consistently below 20

degrees F. (-7 degrees C.), JLG Industries recom-

mends the use of Mobil DTE11.

Aside from JLG recommendations, it is not advisable to

mix oils of different brands or types, as they may not con-

tain the same required additives or be of comparable vis-

cosities. If use of hydraulic oil other than Mobilfluid 424 is

desired, contact JLG Industries for proper recommenda-

tions.

Some machines may be specially equipped with Mobil

EAL224H biodegradable and non-toxic hydraulic oil. This

oil is vegetable oil based and possesses the same anti-

wear and rust protection characteristics as mineral oils,

but will not adversely affect ground water or the environ-

ment when spilled or leaked in small amounts. Mobil

EAL224H has a viscosity of 34 cST at 40° C and a viscosity

index of 213. The operating range of this oil is -18° C to

+83° C.

IT IS RECOMMENDED THAT MOBIL EAL224H HYDRAULIC OIL BE

STORED ABOVE FREEZING (0° C) AS THE OIL MAY APPEAR

CLOUDY AFTER EXPOSURE TO LOW TEMPERATURES FOR

EXTENDED PERIODS OF TIME. THE CLOUDINESS WILL DISAPPEAR

WHEN THE OIL IS WARMED TO AT LEAST 10° C AND AGITATED. DO

NOT ATTEMPT TO "THIN" THE OIL WITH NO.2 DIESEL FUEL. FOR

BEST RESULTS, STORE THE OIL ABOVE FREEZING.

NOTE: Accidentally mixing Mobil EAL224H hydraulic oil with

other mineral oils will cause no loss of performance

characteristics. However, biodegradability may be

reduced and toxicity may be increased, depending

on the oil and level of contamination.

Lubrication Specifications

NOTE: Refer to Lubrication Chart for specific lubrication pro-

cedures..

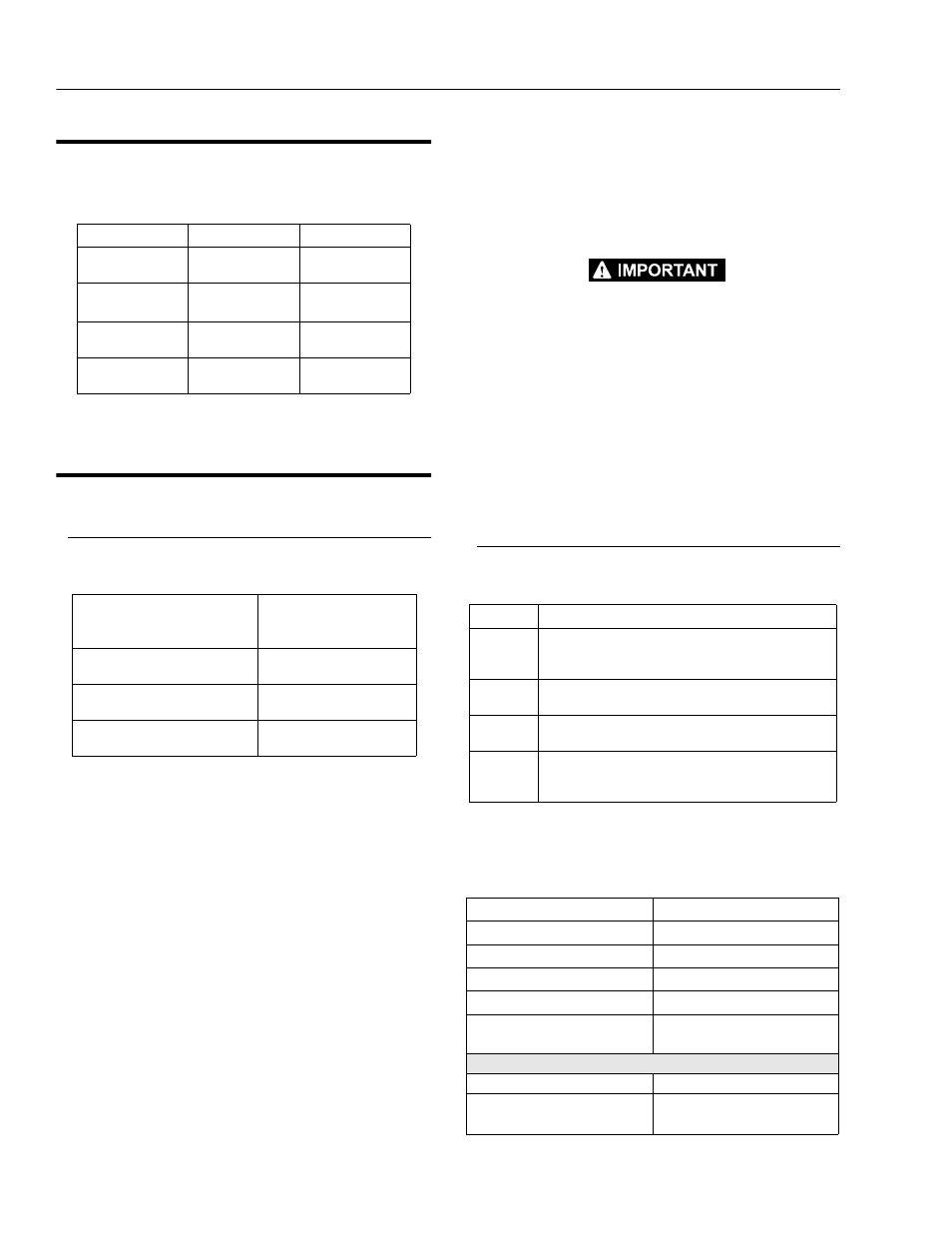

Table 1-1.Torque Requirements

Description

Torque Value

Interval Hours

Wheel Lugs

170 ft. lbs.

(231 Nm)

150

Semi-Track

Wheel Lugs

90 ft. lbs.

(122 Nm)

150

Swing Bearing

(Dry)

220 ft. lbs.

(298 Nm)

50/600*

Swing Bearing

((Loctite)

240 ft. lbs.

(326 Nm)

50/600*

Table 1-2.Hydraulic Oil

Hydraulic System

Operating

Temperature Range

S.A.E. Viscosity

Grade

+0° to + 180° F

(-18° to +83° C)

10W

+0° to + 210° F

(-18° to +99° C)

10W-20, 10W30

+50° to + 210° F

(+10° to +99° C

20W-20

Table 1-3.Lubrication Specifications.

KEY

SPECIFICATIONS

MPG

Multipurpose Grease having a minimum dripping point of 350

degrees F. Excellent water resistance and adhesive qualities; and

being of extreme pressure type (Timken OK 40 pounds minimum).

EPGL

Extreme Pressure Gear Lube (oil) meeting API Ser-

vice Classification GL-5 or Mil-Spec Mil-L-2105.

HO

Hydraulic Oil. API Service Classification GL-3, SAE

10W-20, Viscosity Index 152, e.g. Kendall Hyken 052.

EO

Engine (crankcase) Oil. Gas - API SF/SG class, MIL-L-

2104. Diesel - API CC/CD class, MIL-L-2104B/MIL-L-

2104C.

Table 1-4. Mobil EAL Envirosyn H 46 Specs

Type

Synthetic Biodegradable

ISO Viscosity Grade

46

Specific Gravity

.910

Pour Point, Max

-44° F (-44° C)

Flash Point, Min.

500° F (260° C)

Weight

7.64 lb. per gal.

(0.9 kg per liter)

Viscosity

at 40° C

45 cSt

at 100° C

8.0 cSt

Viscosity Index

153

Updated 2-16-00