Interface and outputs – IKA KS 130 control User Manual

Page 30

Control error codes:

ATTENTION! If an error code is encountered, an audio warning

signal is generated and the red Off signal light goes on in the dis-

play field. First, please try to continue operating by turning the

device off and back on again. If it is still not possible to elimina-

te an errorafter an extended wait, please contact our service

department. If you do so, you should always tell us what error

code has been encountered. This simplifies the process of

tracking down the error and makes it possible to form a prelimi-

nary opinion.

Error code

Error

Cause of the error

Er 2

No communication bet- -Interface not connected

ween PC and control de- -PC is not sending any

vice in remote operation data within the amount

with active watchdog func- of time set by the watch-

tion in Mode 1

dog

Er 3

Internal device tempe-

-Permissible ambient

rature too high

temperature exceeded

Er 4

Motor locked or over-

-Agitator table is being

loaded, Problem with

hindered in its stroke motion

read fork signal

-Internal device error

Er 9

Error while reading

-BLP Logik

stored values.

Er 41

Triac defective

-Internal device error

Er 42

Safety relay defective

-Internal device error

WD

No communication bet- -Interface not connected

ween PC and contol de- -PC is not sending any

vice in remote operation data within the amount

with active watchdog func- of time set by the watch-

tion in Mode 1

dog

30

032007

(KS 130 control version only)

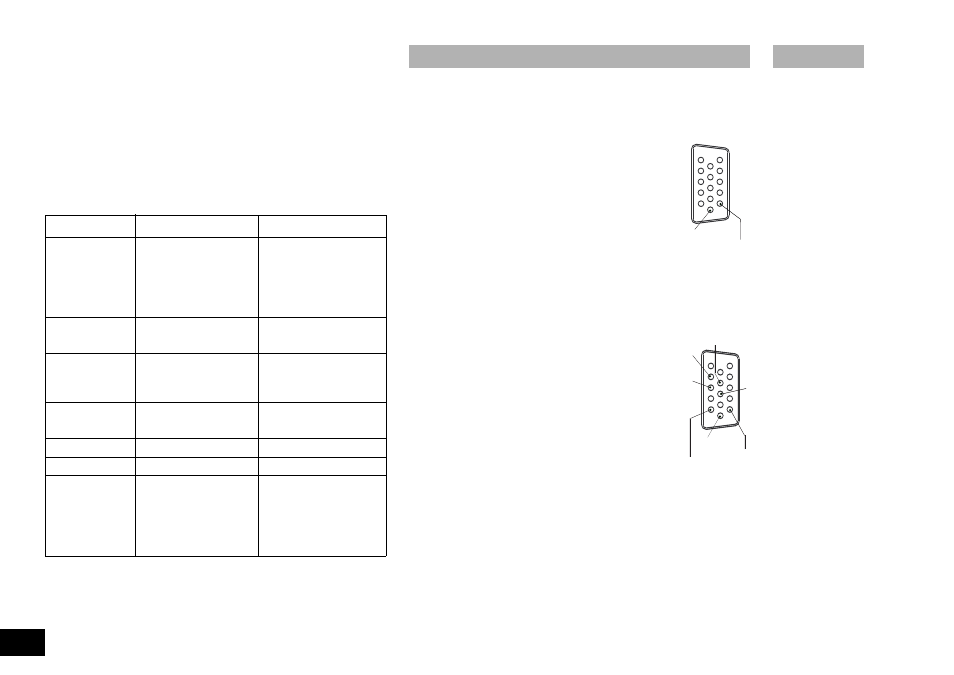

The KS 130 control is equipped with a 15-pin SUB-D connector on the rear

side of the device. The pins are assigned in operatin with analog and seri-

al signals.

Analog autput

Voltage values for the speed measurement quantify

are present on the analog pins.

(10)

Analog GND

(15)

Speed measurement value 1VDC / 1000 rpm

RS 232 C serial interface

The serial assignment of the socket can be used to control the device

externally by means of a PC and a suitable application program.

Configuration of the serial RS 232 C interface

• The function of the interface line between the laboratory device and the

automation system is a selection of the signals specified in

EIA Standard RS 232 C, corresponding to DIN 66020 Part

1. For the assignment of the signals, please refer to the illu-

stration.

• Standard RS 232 C applies to the elctronic properties of

the interfaces and the assignment of signal states in accor-

dance with DIN 66259 Part1.

• Transmission procedure: Asynchronous character

transmission in start-stop

mode

• Type of transmission:

full duplex

• Character format:

Character creation according to the data format

in DIN 66022 for start-stop mode. 1start bit;

7character bits; 1parity bit (even); 1stopbit.

• Transmission speed:

9600 baud

• Data flow conrol:

RTS/CTS hardware handshake

• RTS:

(Pin 7) LOW (positive tension)

/ PC may send

• RTS:

(Pin 7) HIGH (negative tension)

/ PC may not send

Interface and outputs

5

1

0

1

5

1

6

1

1

Analog GND

1V = 1000 1/min

5

1

0

1

5

1

6

1

1

Analog GND

RS232_GND

TxD

RxD

RTS

CTS

1V = 1000 1/min