Transportation, 2 hoisting by crane, Machine weights – Snorkel MB20N-sn0001-0131 User Manual

Page 4: 1 hoisting by fork-lift

Transportation

MB20N/MB26

2.0

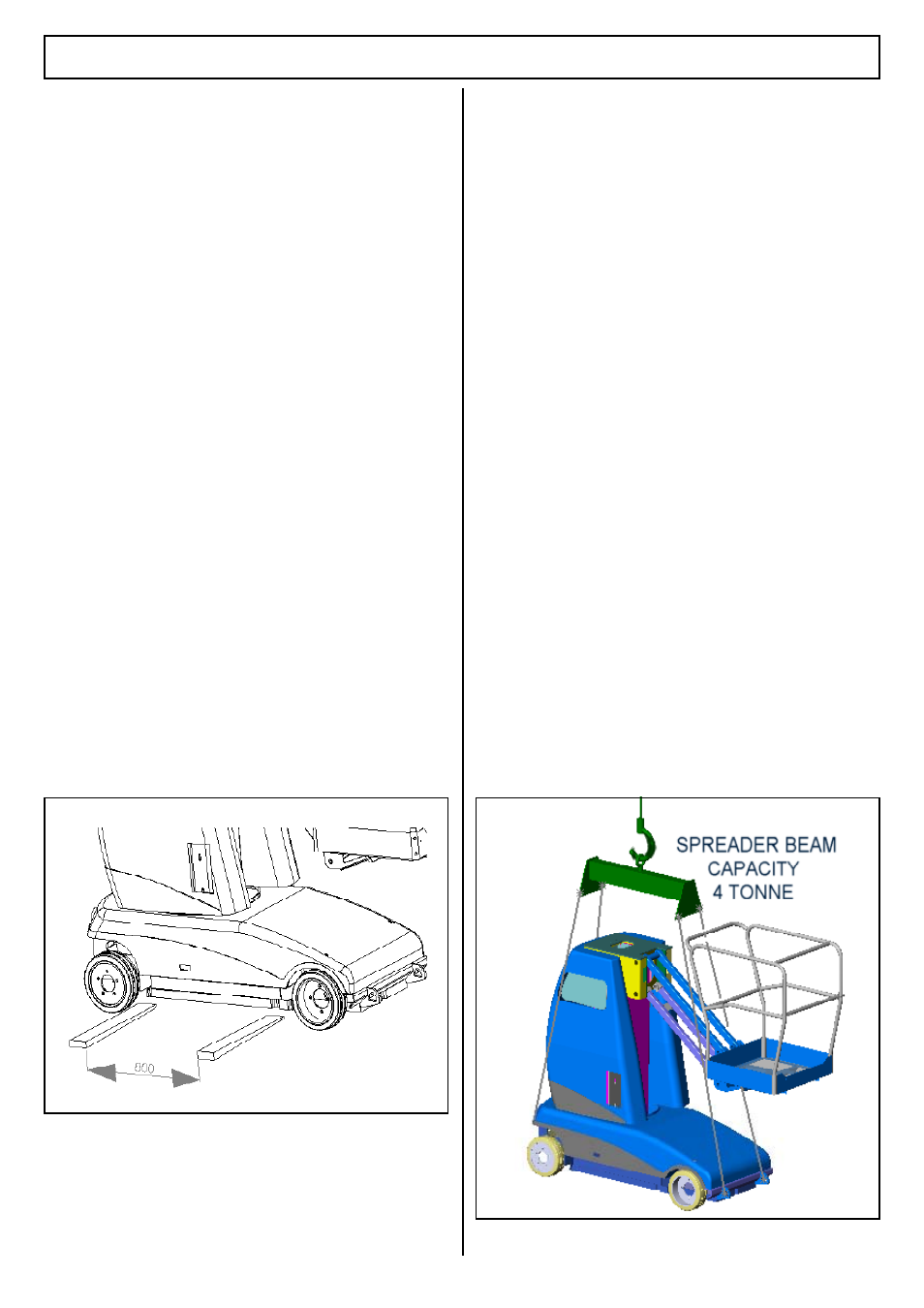

2 Hoisting By Crane

The MB20/26 may be lifted by an overhead hoist/

crane subject to the following strict procedure.

Raise the jib to clear the lifting straps as shown.

Use 4 No. separate lifting straps connected to a

spreader beam. DO NOT use a lesser number of

threaded straps as these could slip and lead to

instability. The recommended minimum capacity of

EACH of the 4 straps is 2 tonne and the minimum

length of each strap is 2 metres. Damage to the

covers and/or cage rails can occur if a spreader

beam is not deployed during a crane lift.

Apply the straps via 1 tonne shackles to each of the 4

lifting lugs on the chassis. See the figure below.

DO NOT apply lifting straps to any other part of the

machine.

The MB20/26 may be lifted by forklift subject to the

following strict procedure.

Ensure that the mast and jib are fully stowed and that

the pothole bars are fully retracted (raised).

Machine Weights

Before transporting or lifting the MB20N/26 machine

be aware of its weight. It is very important to realise

that the centre of gravity of the stowed machine is

approximately 80 cm above ground and in the plane

of the energy chain which is located on the back of

the mast.

MB20N CE Version = 2554 kg

MB20N US Version = 3042 kg

(6708 lbs)

MB26 CE Version = 2413 kg

MB26 US Version = 2950 kg

( 6505 lbs)

In cases of particular difficulties with lifting or shipping

it is possible to remove the single block ballast from

the machine. Remove the 13 screws connecting the

ballast cover to the mast. Undo the 4 bolts connecting

the ballast to the mast and use a forklift to remove the

ballast block. The ballast block weighs 850 kg on the

CE version and 1300 kg on the US version. This

work may not be carried out without the written

permission of UpRight Ireland engineering

department. (Tel. 353 1 2024100).

1 Hoisting by Fork-Lift

Adjust the forks so that the minimum clearance

between them is 800mm as shown below.

Approach the machine from either side but place the

fork as close as possible to the front wheel as shown.

Never approach the MB20 from the front or rear

while fork lifting.

Use maximum forklift tilt as soon as possible when

raising the MB20/26.

If travelling over sloped or uneven ground it is

strongly recommended to temporarily tie the MB20 jib

mount structure to the forklift mast as a safety

precaution.

FRONT

Page 3