Lukas Hydraulic Hoses User Manual

Page 8

8

GB

Periods for tests and replacement

7.

Technical data

8.

Checks:

The hose lines should be inspected for visible damage and defects each time prior to being

placed in service. Moreover, their condition should be checked at least once a year by an

expert

1)

.

1)

An expert is a person who, based on technical training and experience, has enough

knowledge in the field of hydraulics and is familiar enough with the applicable general,

statutory and other binding rules regarding occupational safety that he/she is able to

assess the safe working condition of the product.

Replacement:

The hose lines absolutely must be replaced if they show any damage or if there are doubts

about their durability or functional performance! However, the hose lines should also be

replaced at regular intervals due to aging.

Maximum storage time or service life:

Storage:

4 years from the date of manufacture

Normal use:

6 years (including a maximum of 2 years in storage) from the date of

manufacture

Continuous use: 2 years from the date of manufacture

Operation in use with rescue equipment:

10 years from the date of manufacture

Examples of defects for which a replacement is absolutely necessary:

- Damage to the outer layer up to the insert (e.g. due to chafed areas, cuts, cracks, etc.).

- Embrittlement of the outer layer.

- Deformations of the natural shape of the hose lines (e.g. delaminating, blister formation,

crushed spots, kinks, etc.).

- Unsealed places.

- Damage, deformation or corrosion of the fitting or metal insert (except for light scratches

on the fitting).

- Migration of the hose out of the fitting.

- Storage times and service life exceeded.

Operating fluid:

Mineral oil according to DIN EN ISO 6743-4

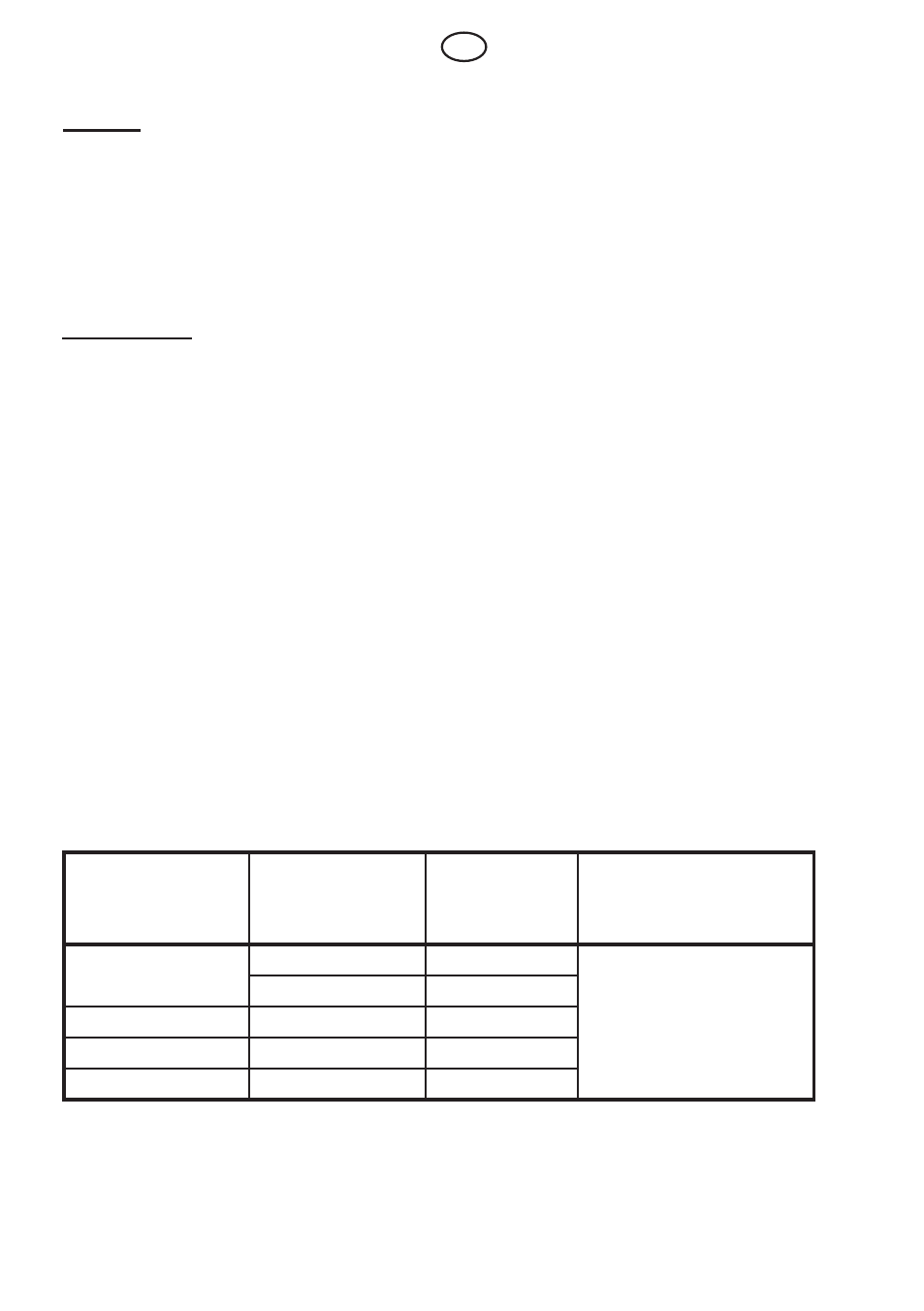

nominal diameter

max. operating

pressure

bending

radius

temperature resistance

[bar]

[mm]

DN 4

700

25

-40°C … +71°C

(-40°F … +160°F)

1600

100

DN 5

2500

175

DN 6

≤720

38

DN 10

≤530

120