2 hydraulic units with combustion engine – Lukas P 650 Series User Manual

Page 34

34

Visual inspection

Hydraulic units

• All hydraulic connections are still tightened

• General tightness, no leakage (sweated oils do not have any in

À uence on the function)

• Obvious damage on the motor/engine, connecting blocks or frame

• Obvious damage to the hydraulic system and/or gasoline tank,

• Side panels present and securely

¿ tted

• Type plate, all activation plates, signs, identi

¿ cation marks and warning labels are present

and legible

• All covers (e.g. exhaust de

À ector) are present and undamaged

• All heat protection mats on the reservoirs are present and undamaged,

• Minimum gap of 10 mm between the reservoirs and hot motor/engine components

• Liquid levels are within the speci

¿ ed tolerances

• Starters are in proper working order and undamaged

• Electric cables are fully functional and undamaged

• Electric starter battery is fully functional and undamaged

• Couplings must be easy to couple

• Dust protection caps must be available

• All necessary accessories (such as sparking plugs, plug spanner and fuel canister) must

be present.

• Toolholder (if available) is undamaged and fully functional

• Carrying handles (if available) are undamaged and fully functional

10.2 Hydraulic units with combustion engine

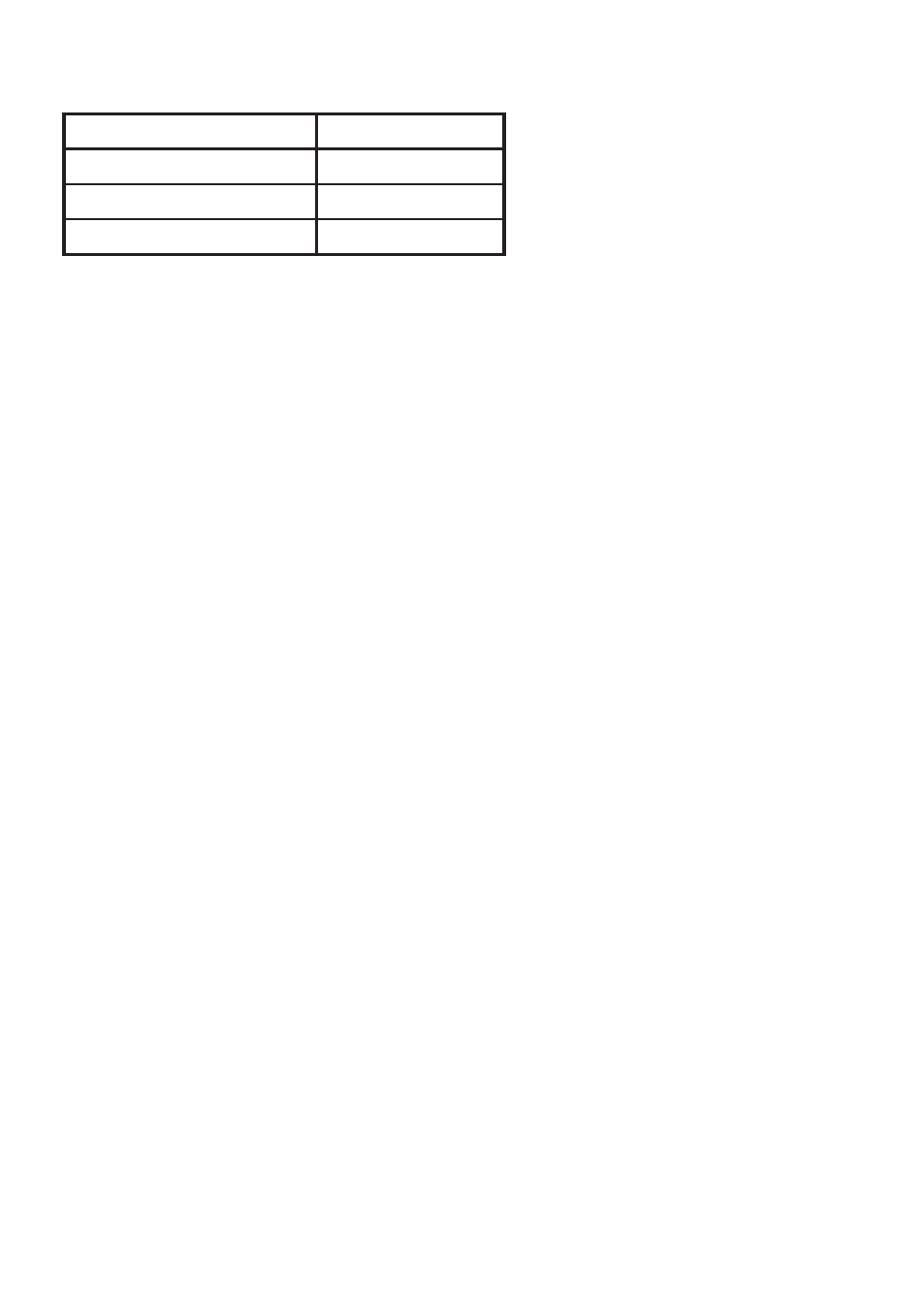

Operating period per day Functional check

up to 1 hour

1 x every year

up to 8 hours

1 x per quarter

up to 24 hours

1 x per month

A functional check should be performed in addition to these intervals if:

-

the unit makes suspicious noises,

-

there are grounds for suspecting that the unit has sustained internal damage.

Should either of the above occur several times within a month or the maximum pressure

is not reached during the functional check, contact LUKAS customer service immediately.

See the chapter "Troubleshooting" for contact details.

10.1.2

Functional

check