Service, Torque chart, Service tools – MBW EXA30 User Manual

Page 10: Exciter disassembly, Exciter assembly, Ervice, Torque chart service tools exciter disassembly

- 7 -

S

ERVICE

Assembly and disassembly should be performed by a

service technician who has been factory trained on MBW

equipment. The unit should be clean and free of debris.

Pressure washing before disassembly is recommended.

• Prior to assembly, wash all parts in a suitable cleaner or

solvent.

• Check moving parts for wear and failure. Refer to the

Replacement section in this manual for tolerance and

replacement cycles.

• All shafts and housings should be oiled prior to pressing

bearings. Also, ensure that the bearings are pressed

square and are seated properly.

• All bearings should be replaced when rebuilding any

exciter or gearbox.

• All gaskets and seals should be replaced after any

disassembly.

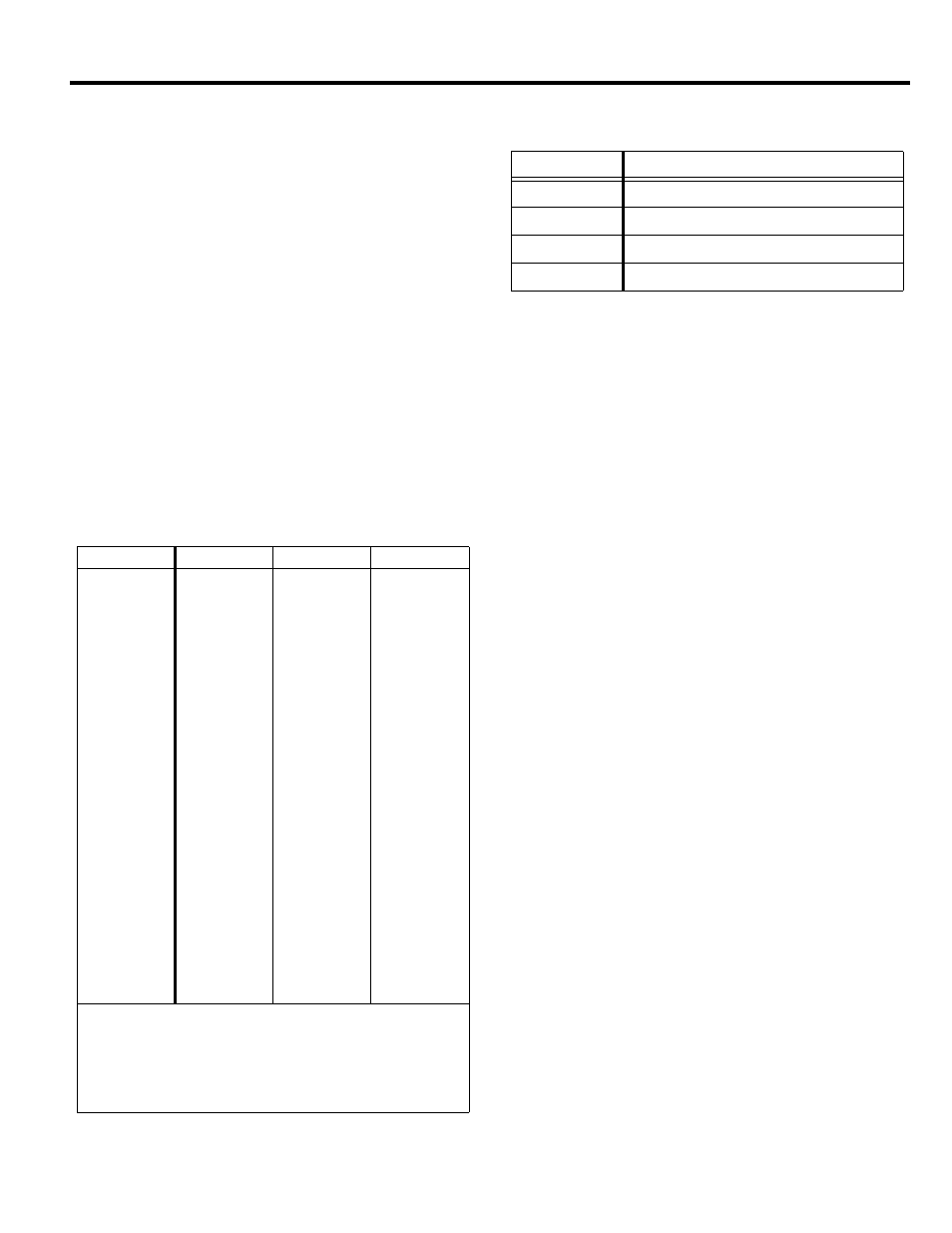

Torque Chart

Service Tools

Exciter Disassembly

1.

Drain exciter oil by removing both plugs (#22) and

slightly tipping exciter assembly towards the plugs.

2.

Remove both socket head cap screws (#24) securing

hydraulic motor (#18). Remove motor.

3.

Remove 14 bolts (#25) securing cover (#9) to exciter

housing and remove cover.

4.

Remove both snap rings (#19) and slide gears (#12

& #10) off.

5.

Remove 8 bolts (#25) securing cover (#8) to exciter

housing, Remove cover.

Note: If removing bearings from shaft assemblies or

housing, bearings MUST be replaced.

6.

Press both exciter shafts (#20) out of housing (#7),

use care not to damage shaft splines.

7.

Remove snap rings (#1) and press both bearings (#6)

from housing (#7).

8.

(A puller will be required to do this step) Remove

snap rings (#6) from both exciter shafts (#20) and

remove inner races.

9.

Remove both snap ring (#1) securing bearings (#4) in

cover (#8). Remove 4 bolts and washers (#23).

10. Support cover (#8) and use a brass punch to tap out

bearings (#4) alternate from side to side of each

bearing to eliminate binding of the bearing.

Exciter Assembly

Refer to Exciter Assembly, page 12.

1.

Press inner race of bearing (#4) onto exciter shaft

(#20) and install snap ring (#6). Repeat procedure on

second exciter shaft.

2.

Press remaining portion of bearing (#4) into cover

(#8) and install snap ring (#1). Repeat procedure on

second bearing.

3.

Press both bearings (#5) into housing (#7) and install

snap rings (#1).

SIZE

GRADE 2

GRADE 5

GRADE 8

1/4-20

49 in

•

lbs

76 in

•

lbs

9 ft

•

lbs

1/4-28

56 in

•

lbs

87 in

•

lbs

10 ft

•

lbs

5/16-18

8 ft

•

lbs

13 ft

•

lbs

18 ft

•

lbs

5/16-24

9 ft

•

lbs

14 ft

•

lbs

20 ft

•

lbs

3/8-16

15 ft

•

lbs

23 ft

•

lbs

33 ft

•

lbs

3/8-24

17 ft

•

lbs

26 ft

•

lbs

37 ft

•

lbs

7/16-14

24 ft

•

lbs

37 ft

•

lbs

52 ft

•

lbs

7/16-20

27 ft

•

lbs

41 ft

•

lbs

58 ft

•

lbs

1/2-13

37 ft

•

lbs

57 ft

•

lbs

80 ft

•

lbs

1/2-20

41 ft

•

lbs

64 ft

•

lbs

90 ft

•

lbs

9/16-12

53 ft

•

lbs

82 ft

•

lbs

115 ft

•

lbs

5/8-11

73 ft

•

lbs

112 ft

•

lbs

159 ft

•

lbs

5/8-18

83 ft

•

lbs

112 ft

•

lbs

180 ft

•

lbs

3/4-16

144 ft

•

lbs

200 ft

•

lbs

315 ft

•

lbs

1-8

188 ft

•

lbs

483 ft

•

lbs

682 ft

•

lbs

1-14

210 ft

•

lbs

541 ft

•

lbs

764 ft

•

lbs

1-1/2-6

652 ft

•

lbs

1462 ft

•

lbs

2371 ft

•

lbs

M 6

3 ft

•

lbs

4 ft

•

lbs

7 ft

•

lbs

M 8

6 ft

•

lbs

10 ft

•

lbs

18 ft

•

lbs

M 10

10 ft

•

lbs

20 ft

•

lbs

30 ft

•

lbs

CONVERSIONS

in

•

lbs x 0.083 = ft

•

lbs

ft

•

lbs x 12 = in

•

lbs

ft

•

lbs x 0.1383 = kg

•

m

ft

•

lbs x 1.3558 = N

•

m

Part No.

Description

16163

Torsion mount install tool

16184

Rubber lubricant (included with 16163)

00709

Exciter shim, .005”

09379

Drum Puller