Set up, Rubber flat washer seat adjust screw – Hornady Seater Die User Manual

Page 2

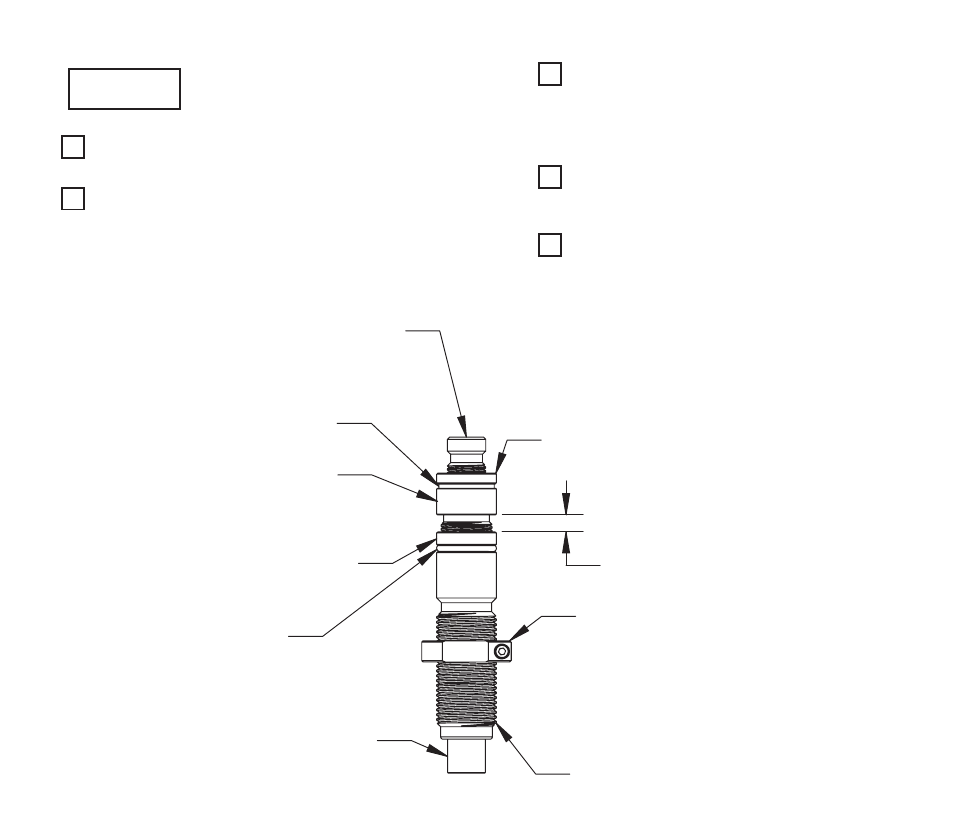

1/4"

Rubber Flat Washer

Seat Adjust Screw

(adjusts bullet seating depth)

Seat Adjust Lock Ring

Sure-Loc Lock Ring

Crimp/Seater Die

Alignment Sleeve

O-Ring

Crimp Adjust Lock Ring

Crimp Adjust Screw

(adjusts bullet seating depth)

set up

1.

As with all dies, disassemble the Crimp/Seater

Die and clean thoroughly.

2.

Reassemble according to illustration, setting the

distance between the Crimp Adjust Screw and

the Crimp Adjust Lock Ring to approximately ¼

inch. When tightened properly, the Crimp Adjust

Lock Ring should have firm tension on the O-ring

against the Seater Die Body.

Depending on the caliber of die set/alignment

sleeve you are using, the Hornady Crimp/Seater Die

will either "taper" or "roll" crimp your cases.

3.

With a case in the shell holder, raise the press

ram to the top of its stroke. Screw the assembled

Crimp/Seater Die into the press until resistance

is felt. This resistance is the case starting to

crimp in the Alignment Sleeve.

4.

Screw the Sure-Loc Lock Ring down against the

press or Lock-N-Load

®

Bushing and lock into

place by tightening the cap screw on the ring.

5.

Loosen the Crimp Adjust Lock Ring while holding

the Crimp Adjust Screw and then back the Crimp

Adjust Screw off approximately ½ turn. Retighten

the Crimp Adjust Lock Ring while holding the

Crimp Adjust Screw.